Essential Documentation for Manufacturing Bare PCBs and FPCs

FlexPros2025-09-02T13:30:43+00:00When placing an order with PICA Manufacturing Solutions for bare Printed Circuit Boards (PCBs) or Flexible Printed Circuits (FPCs), having the correct documentation and files is crucial. This ensures smooth production, meets quality standards, and aligns with your specific requirements. This article outlines the mandatory and good-to-have documents and files essential for manufacturing bare PCBs and FPCs.

Mandatory Documentation and Files

- Gerber Files

Gerber files are the standard format for PCB design and are crucial for the manufacturing process. They contain detailed information about every layer of the PCB, including copper tracking layers, solder mask, legend, and drill files. These files are the blueprint for the PCB manufacturer to follow, ensuring the correct layout and connections.

- Drill Files

Drill files, often included within Gerber files but sometimes provided separately, contain data on all the drilling locations and sizes for vias and mounting holes. Accurate drill files are vital to ensure the correct placement and size of holes, which affect component mounting and the board’s overall functionality.

- Fabrication Drawing

A fabrication drawing includes essential information for the PCB manufacturer, such as board dimensions, number of layers, special fabrication instructions, tolerances, and any specific requirements like impedance control. This document ensures that the manufacturer understands the physical and technical specifications of the PCB.

- Bill of Materials (BOM)

For bare boards, the BOM includes details on materials used for the board layers, finishes, and any other non-component materials required. This document ensures that the manufacturer uses the correct materials, which can impact the board’s performance and durability.

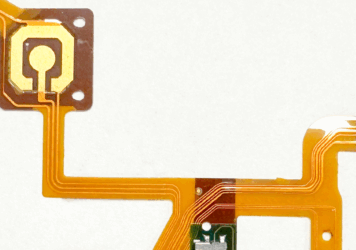

- Material Specifications

Material specifications provide detailed requirements for the substrate materials. This is especially important for FPCs, where material properties can significantly impact performance, such as flexibility, durability, and thermal management.

- Stack-up Information

Stack-up information specifies the layer structure of the PCB, including the thickness of each layer, the material used, and the order of the layers. This is crucial for FPCs, where flexibility and layer order affect the circuit’s performance and reliability.

- Electrical Properties Requirement

This document consolidates the specifications for impedance, resistance, capacitance, and inductance. It ensures that all electrical properties meet the precise requirements necessary for the circuit’s performance, maintaining signal integrity and functional reliability.

- Surface Finish Specifications

Surface finish specifications detail the type of surface finish required for the PCB, affecting solderability and protection against oxidation. This document helps ensure the board’s longevity and reliability in various environments.

- Quality Requirements

Quality requirements specify the standards and quality checks required, possibly including adherence to industry standards like IPC. This document ensures that the PCBs meet quality expectations and industry norms.

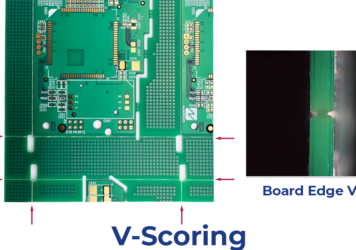

- Panelization Guidelines

If the PCBs are to be manufactured in a panelized form, this document outlines the setup, including tab routing and V-score guidelines. Proper panelization can optimize production efficiency and reduce costs.

- Panel Drawing

If the parts are to be shipped in panel form, it is necessary to provide a detailed panel drawing. This drawing must include all relevant dimensions and specify the quantity of X-outs (defective or non-functional parts) in each panel. This information is essential for accurate manufacturing and quality control.

- Packaging

If the customer has specific packaging requirements, these must be communicated prior to manufacturing. In the absence of specific instructions, standard packaging procedures will be applied to ensure the parts are adequately protected during shipping and handling while meeting customer expectations.

Start Your Project Today!

Contact us today to schedule an appointment to speak with a PICA Manufacturing Solutions engineer today. We look forward to hearing about your project!

Good to Have Documentation and Files

- Netlist File

A netlist file describes the electrical connections between various parts of the circuit. Having this file can aid in testing the PCB after manufacture to ensure all connections are correct.

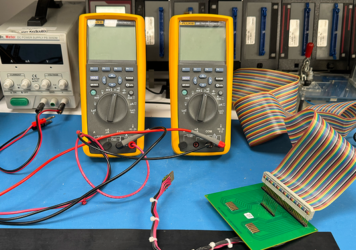

- Test Specifications

Test specifications provide detailed instructions on how to test the PCB during and after manufacturing to ensure it meets design specifications. This helps in identifying and rectifying issues early in the production process.

- Regulatory and Compliance Information

This includes information on RoHS compliance, REACH compliance, conflict minerals reporting, IPC standards, and other industry-specific regulatory requirements. Compliance ensures that your PCBs meet legal and industry standards, avoiding potential penalties and market restrictions.

Providing comprehensive and accurate documentation is crucial for the successful manufacturing of bare PCBs and FPCs at PICA Manufacturing Solutions. This ensures that our team has all the necessary information to produce high-quality boards that meet your specifications and industry standards. By supplying both mandatory and good-to-have documents, you can help us optimize our production processes, reduce errors, and enhance the overall quality of your products.

If you have any questions or need assistance with your documentation, PICA’s expert engineers are always available to help guide you through the process and ensure your project is a success.