Benefits

High Thermal Conductivity: Excellent thermal conductivity allows more efficient heat dissipation in products such as LED lighting and automotive electronics.

High Temperature Capability: They can withstand much higher heat environments. They have a much lower CTE (Coefficient of Thermal Expansion). Reducing the risk of component failure during thermal cycling.

Mechanical Strength and Capability: Ceramic materials have high mechanical strength and rigidity making the PCBs more resistant to physical stress, bending, and warping. Making them much more suitable for electronics in harsh environments subject to vibrations and shocks.

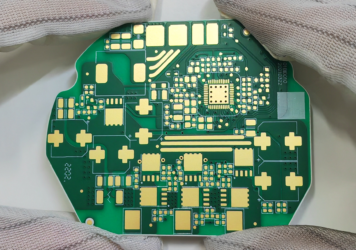

Design Flexibility: Because of their excellent dimensional stability ceramic PCBs are better suited than traditional PCBs for designs with fine traces and high-density interconnects. They provide an excellent platform for miniature and nano electronics.

Long-Term Reliability: These PCBs are less prone to degradation, and aging over time. They are more durable than conventional PCBs.

Applications

Power Electronics: Power modules, motor drives and LED lighting applications.

RF/Microwave Communication: Due to their high frequency performance they are suitable for wireless communications devices, radar systems, satellite communications.

Defense and Aerospace: (Optional since we do not build mil spec PCBs) Avionics, missile guidance systems, and radar systems. Their ruggedness, reliability, and resistance to high temperatures make them well-suited for defense and aerospace applications.

Automotive Electronics: Engine control modules, power management and high temperature operations.

High Power Applications: Solar inverters, Electric vehicle charging stations and industrial motor controls.

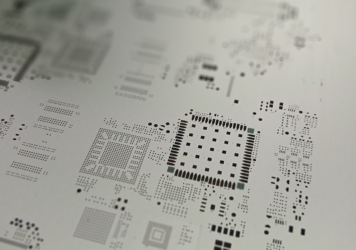

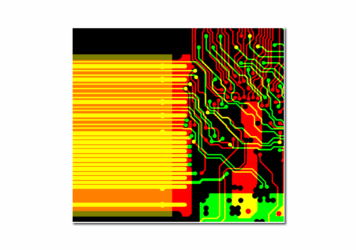

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

Streamlining PCB Production with DFM at PICA Manufacturing Solutions

Design for Manufacturability (DFM) is a proactive process integral to the PICA Way, ensuring a product design aligns with each...

Guidelines for Consigning Components & PCBs to PICA

At PICA Manufacturing Solutions, we occasionally receive printed circuit boards (PCBs) and/or components consigned by our customers for their projects....

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advanced Surface Finishes for Enhanced PCB Performance

This blog is an introduction to a white paper that contains additional information on surface finishes including: Immersion Silver or...

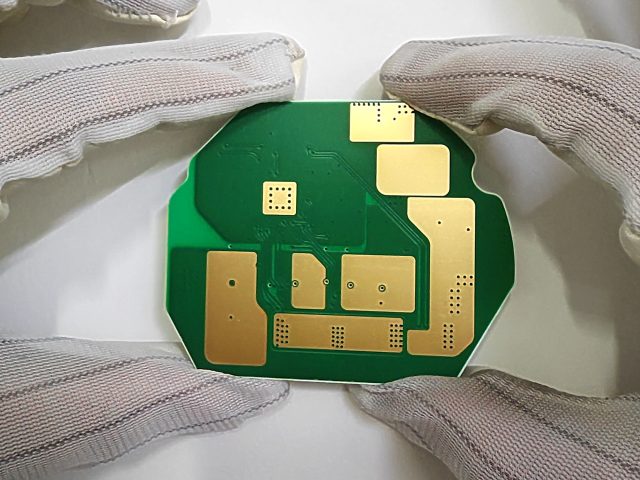

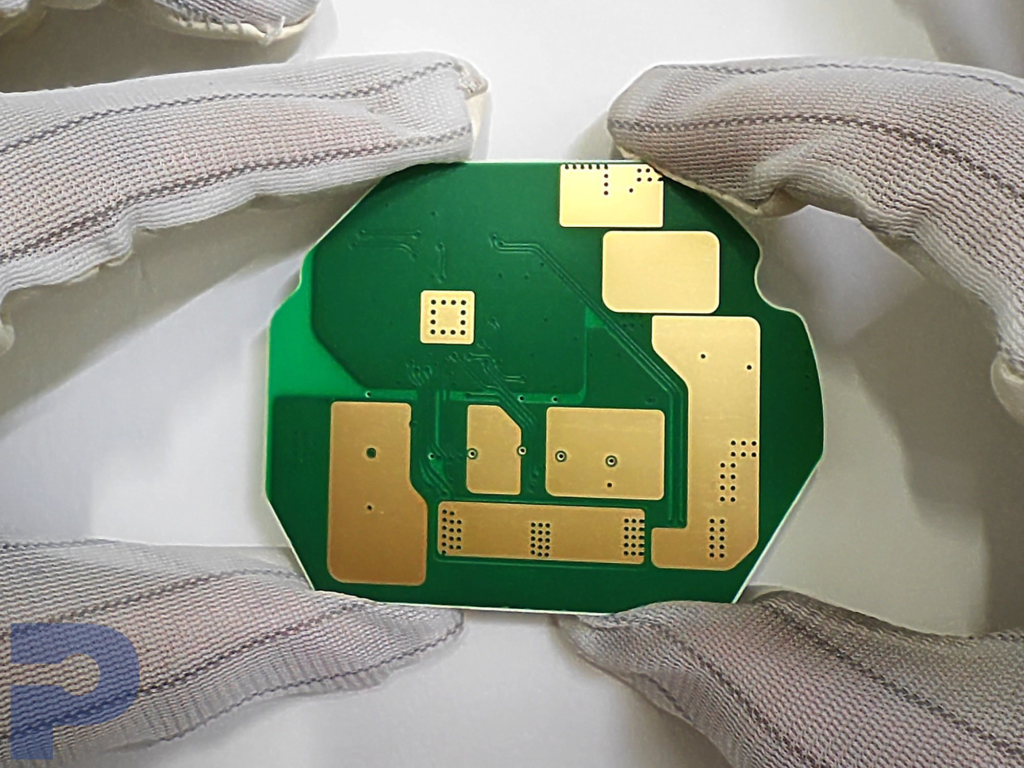

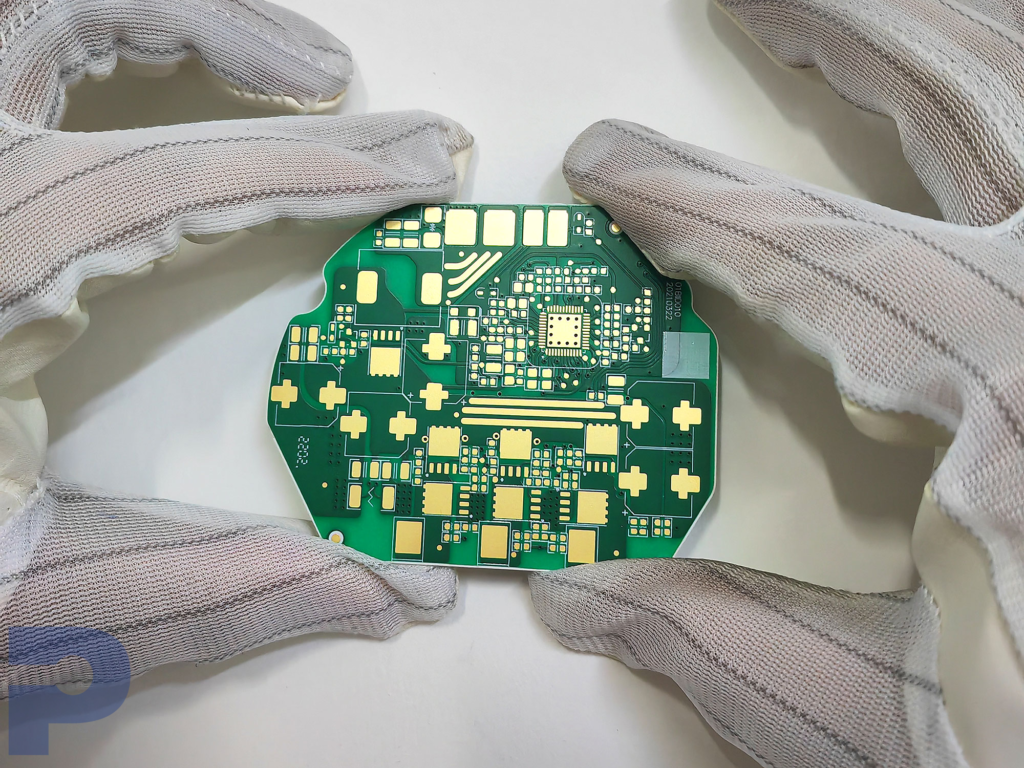

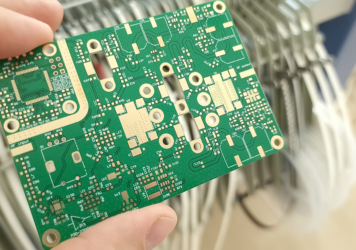

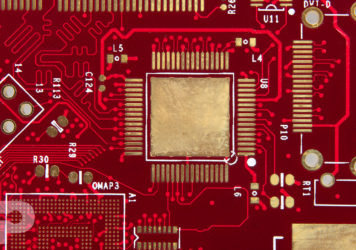

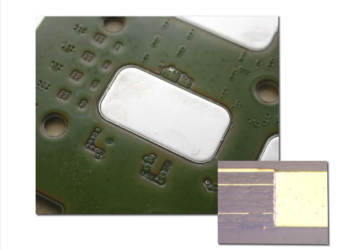

The Rise of Ceramic Substrate Printed Circuit Board

Ceramic substrate PCBs (Printed Circuit Boards) represent a significant advancement in circuit board technology, especially when compared to traditional...

What is Differential Impedance?

In the fast-paced realm of the PCB (Printed Circuit Board) industry, achieving optimal signal integrity is crucial for the...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.