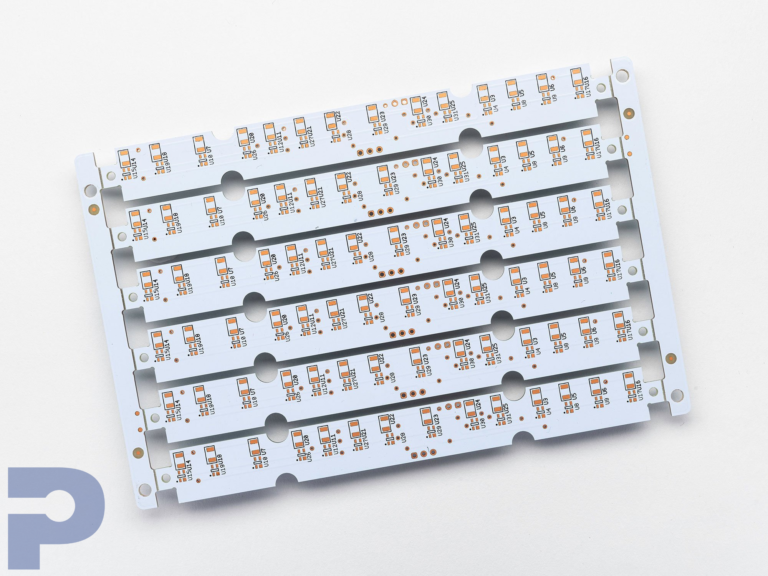

Metal Core Printed Circuit Boards (MCPCBs) revolutionize thermal management in electronic systems. Unlike traditional printed circuit boards, MCPCBs feature a metal core—typically aluminum or copper—sandwiched between layers of dielectric and copper traces. This design significantly enhances heat dissipation and thermal performance, making them indispensable in high-power electronic applications.

The metal core of a metal core printed circuit board (MCPCB) acts as a highly efficient heat spreader, redirecting heat away from sensitive components to less critical areas such as the metal heatsink backing. This property is especially crucial in systems where overheating can lead to performance degradation or even failure.

In essence, metal core printed circuit boards represent a sophisticated solution to thermal challenges in modern electronics, offering unparalleled heat dissipation capabilities and reliability for demanding applications.

At PICA Manufacturing Solutions, metal core printed circuit boards follow similar processes and design rules as the conventional printed circuit boards, allowing for seamless integration into existing production lines. Whether for prototyping or large-scale production, PICA Manufacturing Solutions offers MCPCB manufacturing services tailored to specific requirements, ensuring optimal thermal management solutions for diverse electronic applications.

Contact us with any questions on our MCPCB design and Manufacturing capabilities. We look forward to hearing from you and your design needs.

Benefits

Heat Dissipation: Metal core printed circuit boards dissipate heat efficiently. The metal core acts as a heat sink spreading the heat created by the components over a wider area on the board’s surface to prevent overheating and providing more reliable operation of electronic components.

Improved Reliability: They maintain cooler heat management. By maintaining lower temperatures Metal core printed circuit board’s contribute to improved reliability and longevity of electronic devices. Cooler components experienced less stress and are less prone to failure due to thermal expansion and solder joint fatigue.

Thermal Management: Metal core printed circuit boards provide better thermal management capabilities and improved CTE (coefficient of thermal expansion) which allows better function of heat generating components and enables the designing in of higher power components.

Applications

Metal core printed circuit boards are used in the following applications:

Medical Devices: Where precise and exact electronic components are required, and thermal management is critical.

Automotive Electronics: Offering thermal management in rugged and heat prone environments.

LED Lighting: Controlling and lowering the heat generated by LEDs.

Power Supplies: Devices that generate power and thus heat by helping to lower that heat.

Consumer Electronics: Audio amplifiers, RF Modules, solar inverters, and computer hardware including date storage.

For more specific and detailed information about MCPCBs and PICA’s experience and capabilities click here.

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.