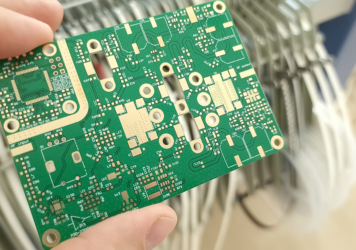

For more technical information on PICA’s Printed Circuit Boards capabilities, click the button below.

Benefits

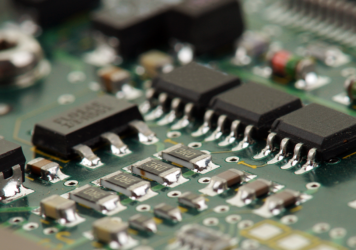

Single-Sided PCBs:

Simplicity and lower cost of production.

Easier to design and manufacture.

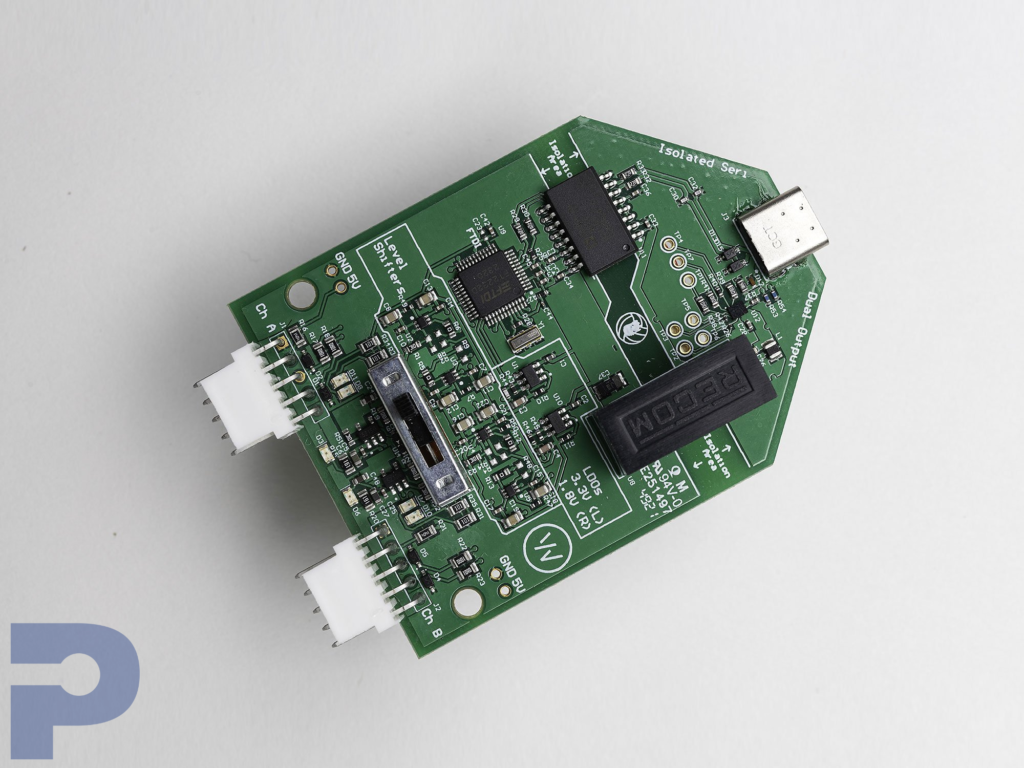

Double-Sided PCBs:

Increased circuit density and complexity compared to single-sided PCBs.

Ability to incorporate surface-mount components on one side.

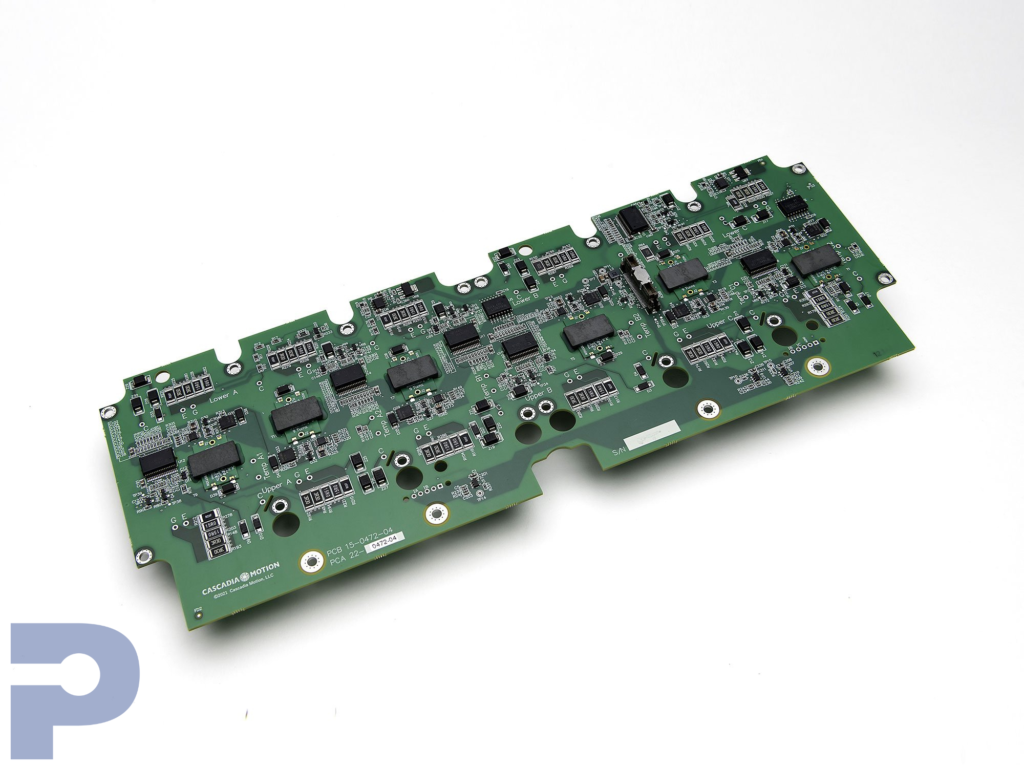

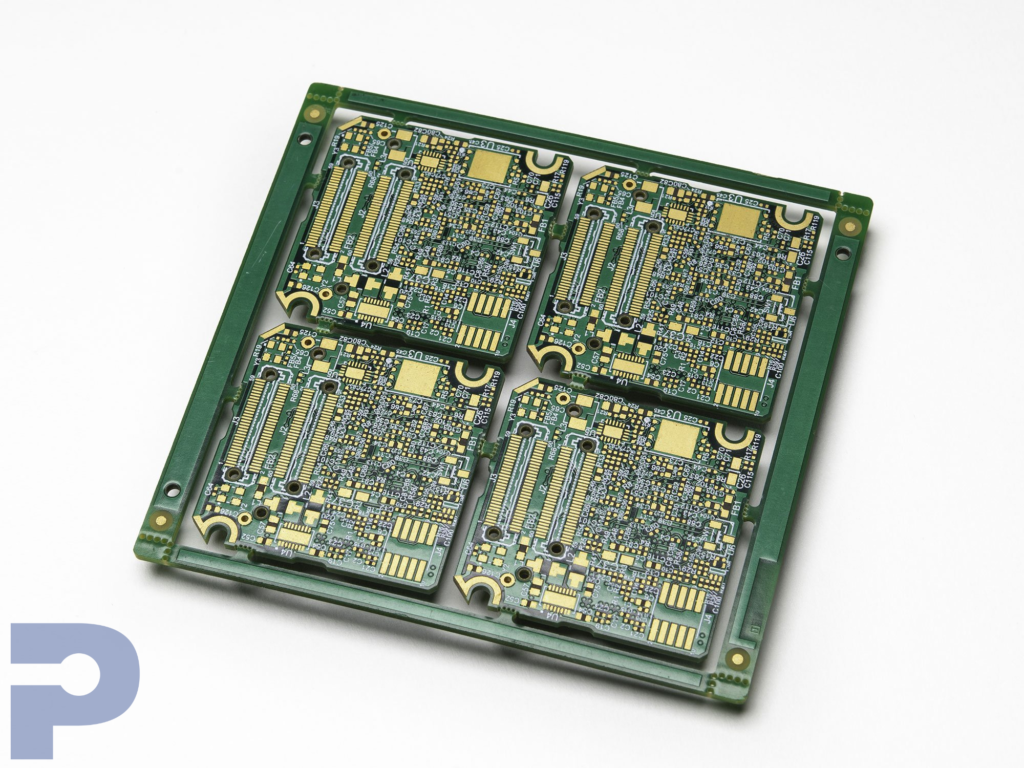

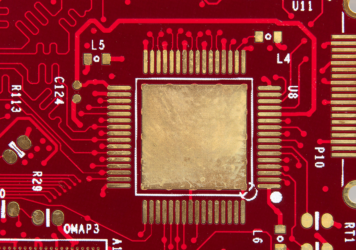

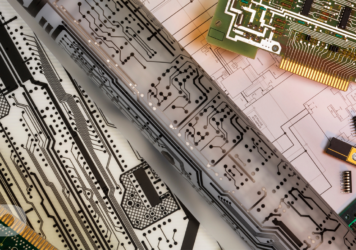

Multi-Layer PCBs:

Higher component density and complex circuitry.

Improved signal integrity and reduced electromagnet interference.

Applications

Single-Sided PCBs:

Low complexity and cost-sensitive electronics such as calculators, remote controls, and basic control systems.

Double-Sided PCBs:

Consumer electronics, audio/video equipment, industrial controls. Automotive electronics and a wide range of electronic devices.

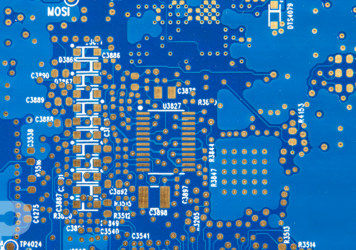

Multi-Layer PCBs:

High performance computers, smartphones, networking equipment, medical devices, aerospace systems, automotive electronics and any electronics requiring advanced functionality and miniaturization.

Understanding PCB Via Holes: Through-Holes, Blind Vias, Buried Vias, & More

Printed Circuit Boards (PCBs) form the backbone of modern electronic devices, providing the physical platform for mounting and interconnecting electronic...

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

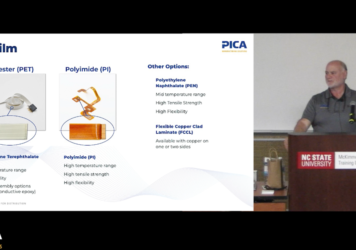

Driving Innovation in PCB Manufacturing: Insights from PCB Carolina 2024

PCB Carolina 2024 brought together industry leaders to explore advancements in PCB design and manufacturing. Joe DiPalermo, our Director of...

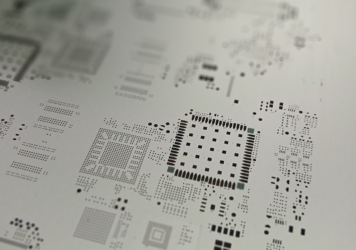

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

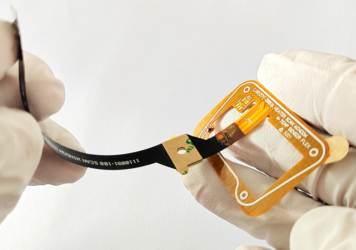

Common Mistakes Made by PCB Designers When Designing Flexible Circuits (FPCs)

Flexible Printed Circuits (FPCs) are widely used due to their lightweight, flexible, and compact nature, making them ideal for...

Guidelines for Consigning Components & PCBs to PICA

At PICA Manufacturing Solutions, we occasionally receive printed circuit boards (PCBs) and/or components consigned by our customers for their projects....

Essential Documentation for Manufacturing Bare PCBs and FPCs

When placing an order with PICA Manufacturing Solutions for bare Printed Circuit Boards (PCBs) or Flexible Printed Circuits (FPCs), having...

Printed Circuit Board (PCB) Via Protection: Strategies and Standards

This blog is an introduction to a larger white paper that features 7 different via protection types. Download the full white...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.