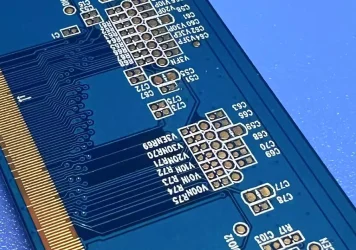

As technology continues to advance at a rapid pace, the demand for smaller, faster, and more powerful electronic devices has reached an all-time high. This is where Fineline PCB / High Density Interconnect (HDI) PCB Electronics Manufacturing comes into play, revolutionizing the world of electronics. These cutting-edge circuit boards are becoming the go-to solution for designers and engineers, offering a higher density of components and interconnections than traditional PCBs.

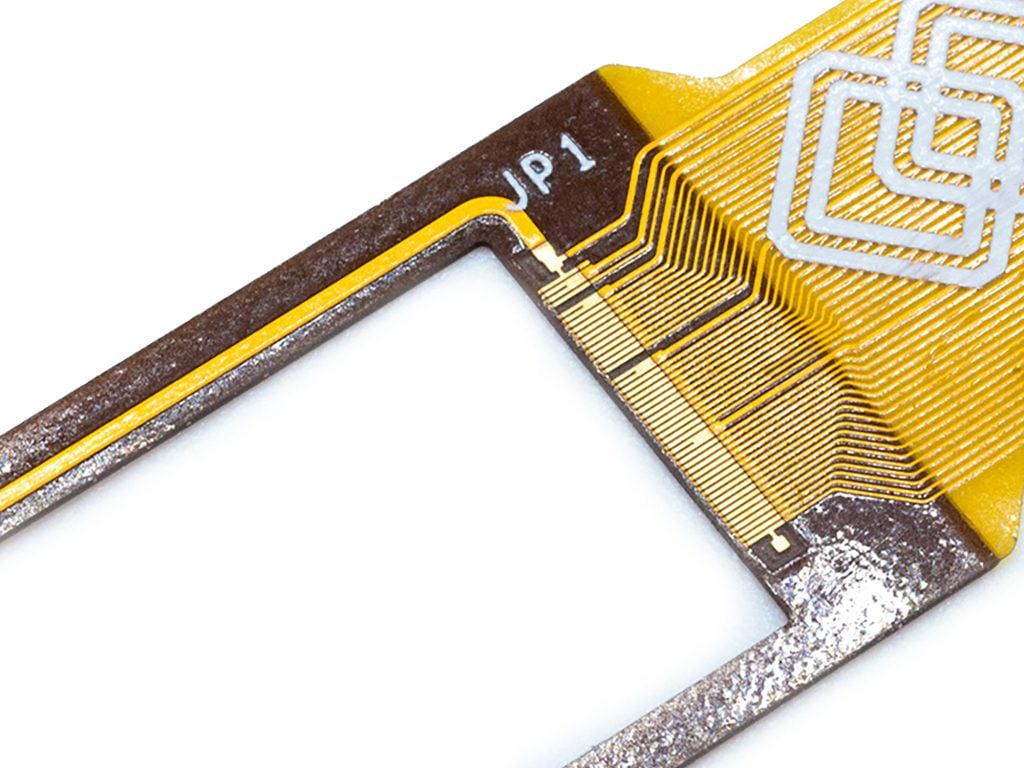

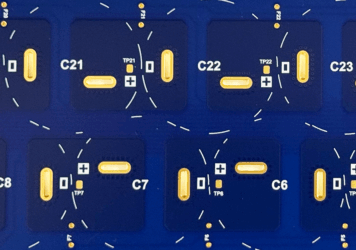

One of the key advantages of Fineline PCB / High Density Interconnect PCBs is their ability to accommodate a greater number of components in a smaller space. By utilizing intricate layers of copper traces and vias, these advanced circuit boards enable the transmission of signals and power between different components with utmost efficiency. This breakthrough technology allows for a more compact and efficient design, resulting in electronic devices that are not only smaller and more lightweight but also deliver superior performance.

The production process of these intricate circuit boards involves several steps that require precision and expertise. It all begins with Laser Direct Imaging (LDI) that can achieve line and space down to 2mils in mass production and 1 mil in small volume. The next step involves laser drilling, which creates tiny holes for interconnections, allowing for a higher density of components. Then, a series of electroplating processes is employed to form the conductive pathways, followed by the application of multiple layers of insulating material. Finally, the PCB is subjected to rigorous Automatic Optical Inspection (AOI) and flying probe testing to ensure its reliability and functionality.

In conclusion, the production of Fineline PCB / High-Density Interconnect (HDI) PCBs is a complex and intricate process that demands the expertise of skilled engineers and technicians. From designing the layout to laser drilling, electroplating, and layering, each step is executed with precision to create high-quality Fineline PCB / High Density Interconnect PCBs.

These compact and powerful circuit boards are at the forefront of innovation in the electronics industry, enabling the development of smaller, more efficient, and more advanced electronic devices that shape our modern world.

For technical information on PICA’s Fineline Flex PCB capabilities, click the button below.

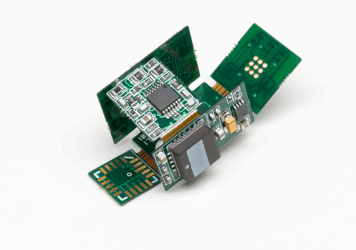

Designing Rigid-Flex Circuits: What Engineers Need to Know

Rigid-flex PCBs combine the best of both worlds—the durability of rigid boards and the versatility of flexible circuits—into a...

Explore the Possibilities of Flexible Circuit Design with the PICA Flex Sample Kit

Designing flexible circuits isn’t just about choosing the right materials, it’s about understanding how all the pieces come together under...

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing When it comes to PCB and flex circuit manufacturing,...

PICA Manufacturing Solutions 30th Anniversary

From Flexible Circuits to Flexible ThinkingOur journey began in 1995 through a strategic partnership with M-Flex, providing engineering and sales...

Guide to PCB & FPC Manufacturing Processes

This blog is an excerpt from the white paper Guide to PCB & FPC Manufacturing Processes: Subtractive, Semi-Additive & Additive...

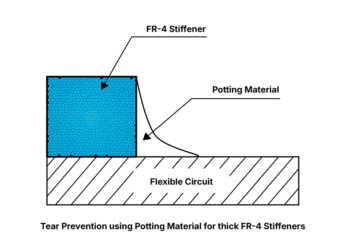

How to Protect Your Flex Circuits: Strain Relief and Tear Resistance Strategies

How to Protect Your Flex Circuits: Strain Relief and Tear Resistance StrategiesFlexible circuits—such as FFCs, FPCs, and rigid-flex assemblies—offer unparalleled...

Designing High Voltage PCBs: Key Layout and Material Considerations

When working with high-voltage circuits, design priorities shift. While many PCBs focus on high-speed signaling, impedance control, or component density,...

The Rise of the Nimble Enterprise: Why Outsourcing Supply Chain Expertise Makes Strategic Sense

There was a time when business success was measured by how much a company could do in-house. From raw material...