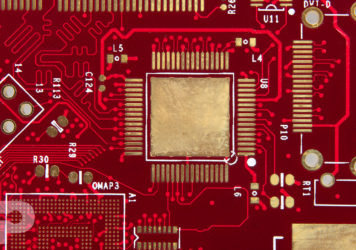

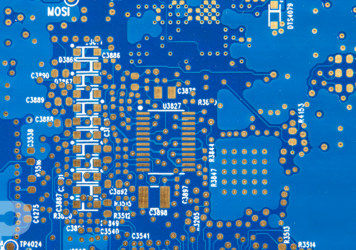

Blind and buried vias are essential components in Printed Circuit Board (PCB) design, enabling complex electrical connections within layers of a circuit board while optimizing space in compact electronic devices. These vias require creating tiny apertures and pathways in the substrate, typically comprised of FR-4 or other high-performance materials, to facilitate seamless connections throughout the board, especially when spatial constraints demand advanced solutions.

Blind vias connect outer layers to one or more inner layers, saving space and minimizing signal stubs during drilling, which enhances signal integrity. Buried vias establish connections solely within inner layers, conserving valuable real estate without disturbing top or bottom layer components or traces. These vias are particularly prominent in High-Density Interconnect (HDI) PCBs, crucial for miniaturization and enhanced performance in devices like cell phones, laptops, wearables, and medical equipment.

However, integrating blind and buried vias poses challenges, adding complexity and escalating production costs. Careful drill depth consideration is vital to avoid signal distortion or improper connections, necessitating collaboration with PCB manufacturers to optimize design and mitigate manufacturing risks.

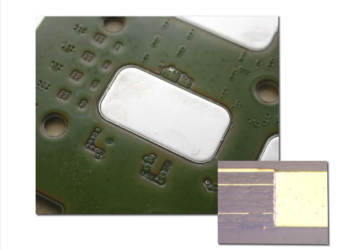

Manufacturing these vias involves meticulous drilling, whether through mechanical or laser methods, and plating processes, as outlined in PICA internal workmanships. Precision is crucial to ensure reliable connections and mitigate risks of voids or pinholes in solder joints.

At PICA, we specialize in blind and buried via technology, employing laser drilling, vapor formation, dielectric material application, and precise layer stacking and lamination. Laser technology controls via size, shape, and depth, ensuring reliable connections in complex circuitry while minimizing interference and crosstalk.

Beyond manufacturing, we provide technical consultancy, offering design insights and manufacturing advice to clients. With PICA, you can trust that your blind and buried Microvias meet the highest standards of performance and reliability. Contact us for inquiries about our capabilities with blind and buried vias.

All too often Printed Circuit boards are viewed as simple two-dimensional surfaces. Nowhere is this oversimplification more evident than in the complex structure of Vias. These essential structures are critical to the form and function of any PCB with more than a single layer. Without these vias modern electronics would not be possible in the way we know them today. This paper delves into the importance of via protection, what the Institute for Printed Circuits (IPC) recommends, the types of via protection, their applications, and the inherent limitations and trade-offs.

Printed Circuit Boards (PCBs) form the backbone of modern electronic devices, providing the physical platform for mounting and interconnecting electronic components. Among the essential elements in PCB design are vias—small holes that allow electrical connections between different layers of the board. Vias play a role in ensuring efficient routing of electrical signals, managing thermal performance, and optimizing space within complex multi-layer boards.

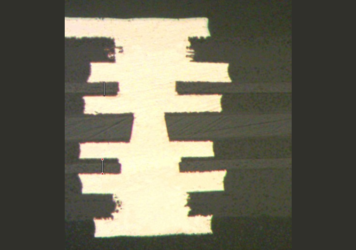

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

Essential Documentation for Manufacturing Bare PCBs and FPCs

When placing an order with PICA Manufacturing Solutions for bare Printed Circuit Boards (PCBs) or Flexible Printed Circuits (FPCs), having...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advanced Surface Finishes for Enhanced PCB Performance

This blog is an introduction to a white paper that contains additional information on surface finishes including: Immersion Silver or...

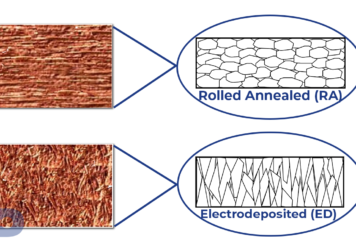

The Best Copper Conductor for Flex-to-Install & Dynamic Applications

When it comes to choosing the right conductor material for flexible printed circuits (FPC), the primary consideration revolves around how...

Printed Circuit Board (PCB) Via Protection: Strategies and Standards

This blog is an introduction to a larger white paper that features 7 different via protection types. Download the full white...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...

6-Layer ELIC Rigid Flex Printed Circuit Board / Rigid Flex PCB

A 6-Layer ELIC (Every Layer Inter-connect) Rigid Flex Printed Circuit Board / Rigid Flex PCB is an advanced and...