Benefits

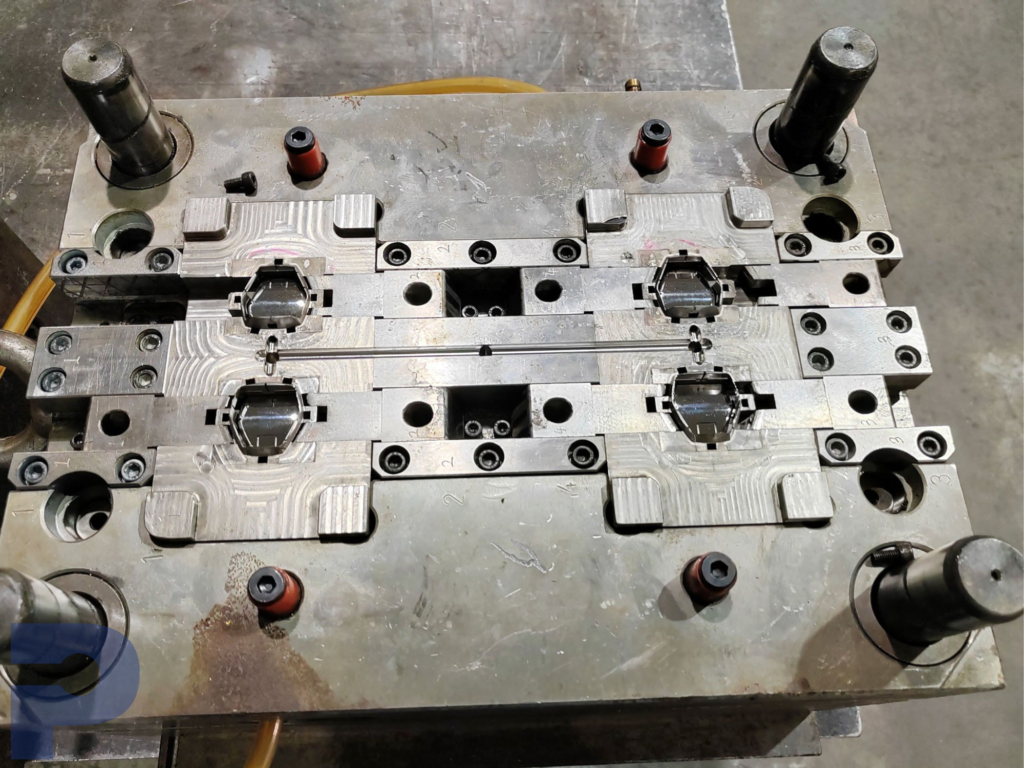

High Efficiency: Injection molding is a highly efficient process that can produce large amounts of parts quickly, enabling cost-effective mass production.

Precision and Complexity: The process allows for the creation of complex and intricate designs with high precision, ensuring consistent quality in each part.

Material Variety: A wide range of plastic materials can be used in injection molding allowing manufacturers to choose materials with specific properties to suit the application.

Low Waste: injection molding generate minimal scrap, as any excess material can be reground and reused for future production runs.

Automation: Injection molding can be highly automated reducing labor costs and minimizing human error.

Surface Finish: The process can produce parts with excellent surface finish, eliminating the need for additional finishing operations in many cases.

Design Flexibility: Injection molding provides designers with the flexibility to incorporate various features such as undercuts and inserts into the mold, expanding the range of possible designs.

Applications

Automotive Parts: Dashboards, bumpers, interior components and more.

Consumer Goods: Bottles, containers, toys, and kitchenware.

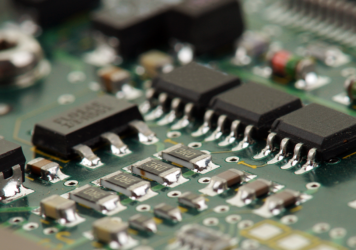

Electronics: Housings for electronic components. Connectors and enclosures.

Medical Devices: Syringes, vials, medical equipment components.

Packaging: Caps, closures, and packaging containers.

Aerospace Components: Various parts for aircraft and space vehicles.

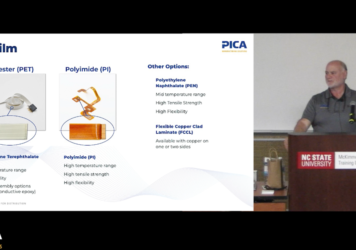

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

Driving Innovation in PCB Manufacturing: Insights from PCB Carolina 2024

PCB Carolina 2024 brought together industry leaders to explore advancements in PCB design and manufacturing. Joe DiPalermo, our Director of...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

Compliance: Ensuring Safety and Performance in Flexible Printed Circuit Manufacturing

When developing and manufacturing flexible printed circuits (FPCs), adhering to industry standards ensures reliability, safety, and performance. Two pivotal standards...

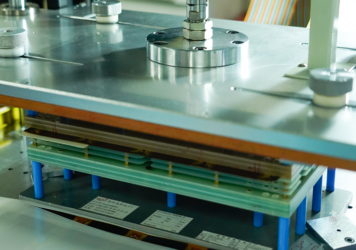

Understanding Tooling in Flex Printed Circuit Manufacturing: Fixtures, Artwork, and Testing (Part 2)

In Part 1 of this series, we discussed the essential role of mechanical tooling in Flexible Printed Circuit (FPC) manufacturing....

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Why X-Ray inspection is essential in flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA) processes

In the realm of flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA), X-ray inspection...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.