For technical information on PICA’s Assembly capabilities, click the button below.

Benefits

Efficiency: Allows for more efficient production processes. Specialized tasks can be assigned to different teams and or automated systems thus streamlining the manufacturing process.

Cost-Effectiveness: By using prefabricated components, manufacturers can reduce production costs as they avoid the need for individual customer manufacturing of each part.

Quality Control: Since components are produced under strict quality standards, the final assembly will have higher quality and reliability.

Scalability: By using component assembly manufacturers can easily scale production rates by the number of parts being assembled. Modern pick and place machines allow for the consistent and reliable assembly of thousands of parts as needed.

Time-Savings: By using modern machines such as pick, and place and wave solder production is quick and efficient.

Design Flexibility: A wide range of parts and components can be incorporated into the assembly process as needed.

Interchangeability: Components are often interchangeable, making maintenance and repairs easier and more cost-effective.

Safety: With better quality control and precision in the assembly process, the risk of defects and failures is reduced enhancing overall product safety.

Applications

Manufacturing: Component assembly is widely used in manufacturing industries such automobiles, computers, appliances, machinery, and equipment.

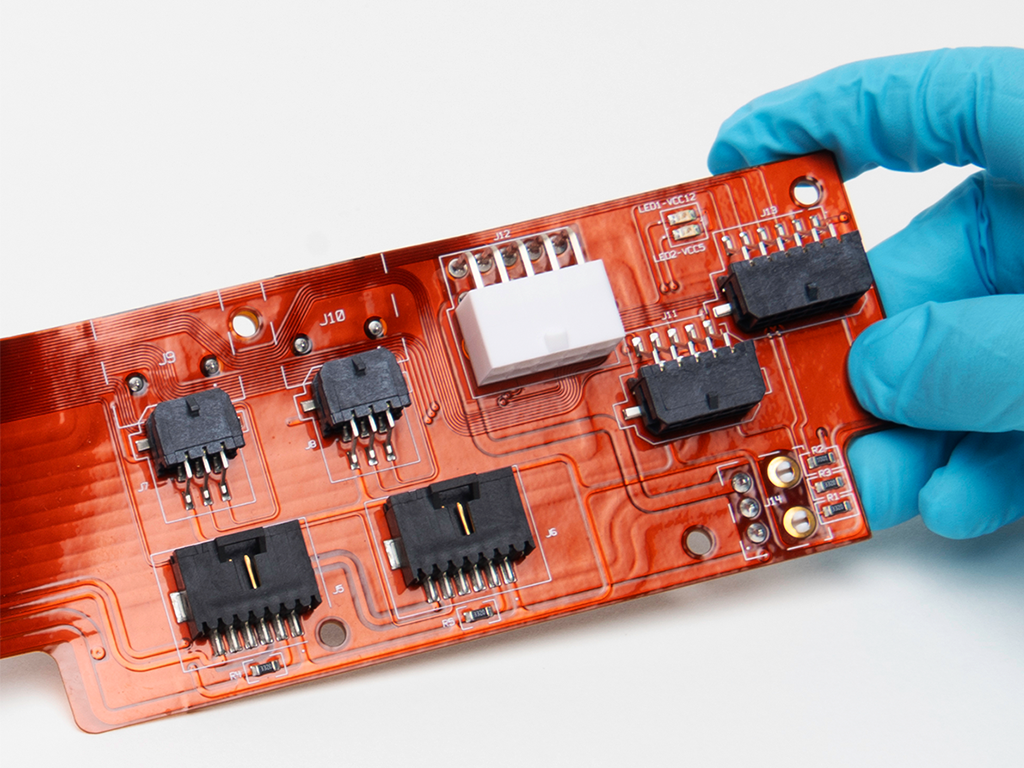

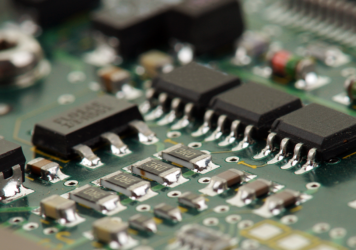

Electronics: This technology is used in putting together integrated circuits, resisters, capacitors, and other electronic components onto circuit boards to create electronic devices.

Construction: Can be used for putting together prefabricated, building elements like walls and floors.

Robotics: It is used in constructing robotics, such as motors and sensors and actuators creating functional robotic systems.

Aerospace: It is crucial for constructing aircraft and spacecraft ensuring the precise integration of various components for safe and reliable operation.

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

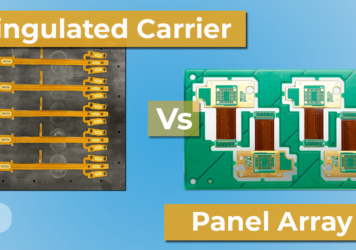

Navigating SMT Assembly Methods for Flexible Circuits Part 2

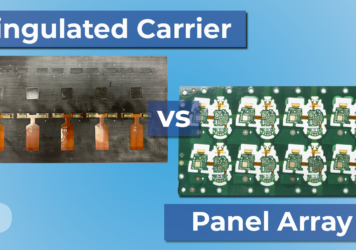

Part 2: Comparing Panel Array vs. Singulated Carrier AssemblyIn the first part of this series, we explored the key considerations...

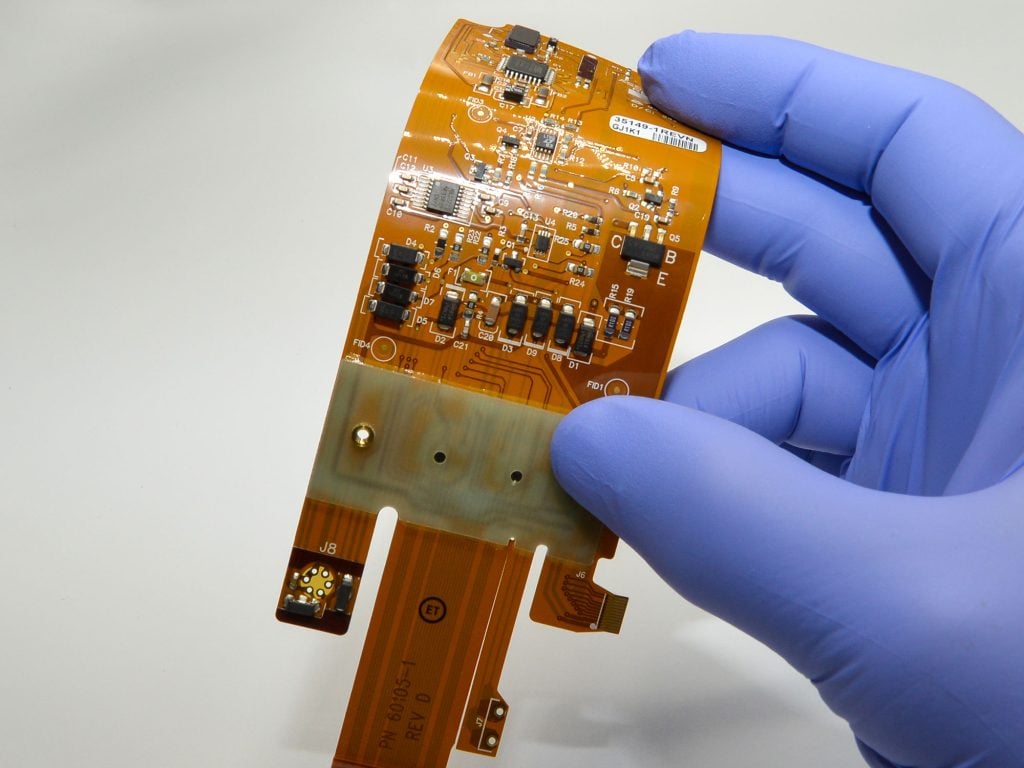

Navigating SMT Assembly Methods for Flexible Circuits

This blog is the first in a two-part series that delves into the critical factors you need to consider when...

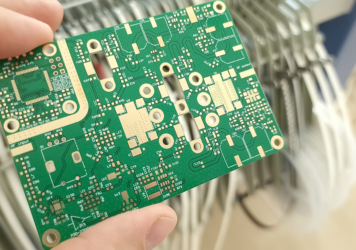

Guidelines for Consigning Components & PCBs to PICA

At PICA Manufacturing Solutions, we occasionally receive printed circuit boards (PCBs) and/or components consigned by our customers for their projects....

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

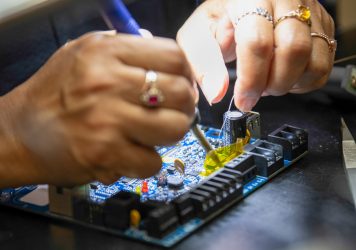

Advance Soldering Techniques for Printed Circuit Board Assembly

Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy,...

Large Thermal Mass Component Hand Soldering

While mass soldering processes dominate soldering applications, hand soldering remains critical in electronics manufacturing. Existing processes (e.g. convection oven reflow,...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.