Thermal Management is a crucial consideration in electronic devices to ensure they operate within safe temperature ranges and maintain optimal performance and reliability. Both thermal vias and copper inlays / embedded solutions are effective methods of enhancing heat transfer and dissipation of circuit boards

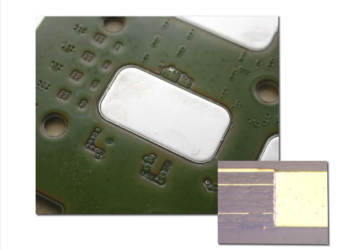

PICA provides a number of thermal management solutions to reduce heat transfer and dissipation including copper thermal inlays, metal clad printed circuit boards with aluminum or copper substrates.

Thermal vias help transfer heat from one layer of the printed circuit board to another. The heat travels through the vias to the outer layers of the board where it can be dissipated more effectively.

Copper is an excellent conductor of heat so incorporating copper elements as we do at PICA, can significantly improve the thermal management of the boards. We use three technologies including: copper inlays, copper plans and copper filled vias.

Metal-clad PCBs with aluminum substrates induce thermal conductivity 1.0 to 12 w/m.k. while double-sided metal-clad aluminum boards provide superconducting thermal material to 122W/m.k.

It should be noted that whatever technology is used for thermal management depends on specific factors such as the application of the PCB, the component arrangement, power dissipation and overall design. A comprehensive thermal analysis and careful design considerations are needed to achieve the desired thermal performance of the board and the board within the end product.

PICA works closely with our customers to help them to evaluate all of these factors and choose the best thermal solution design for their PCBs.

For technical information on PICA’s Engineering expertise, click the button below.

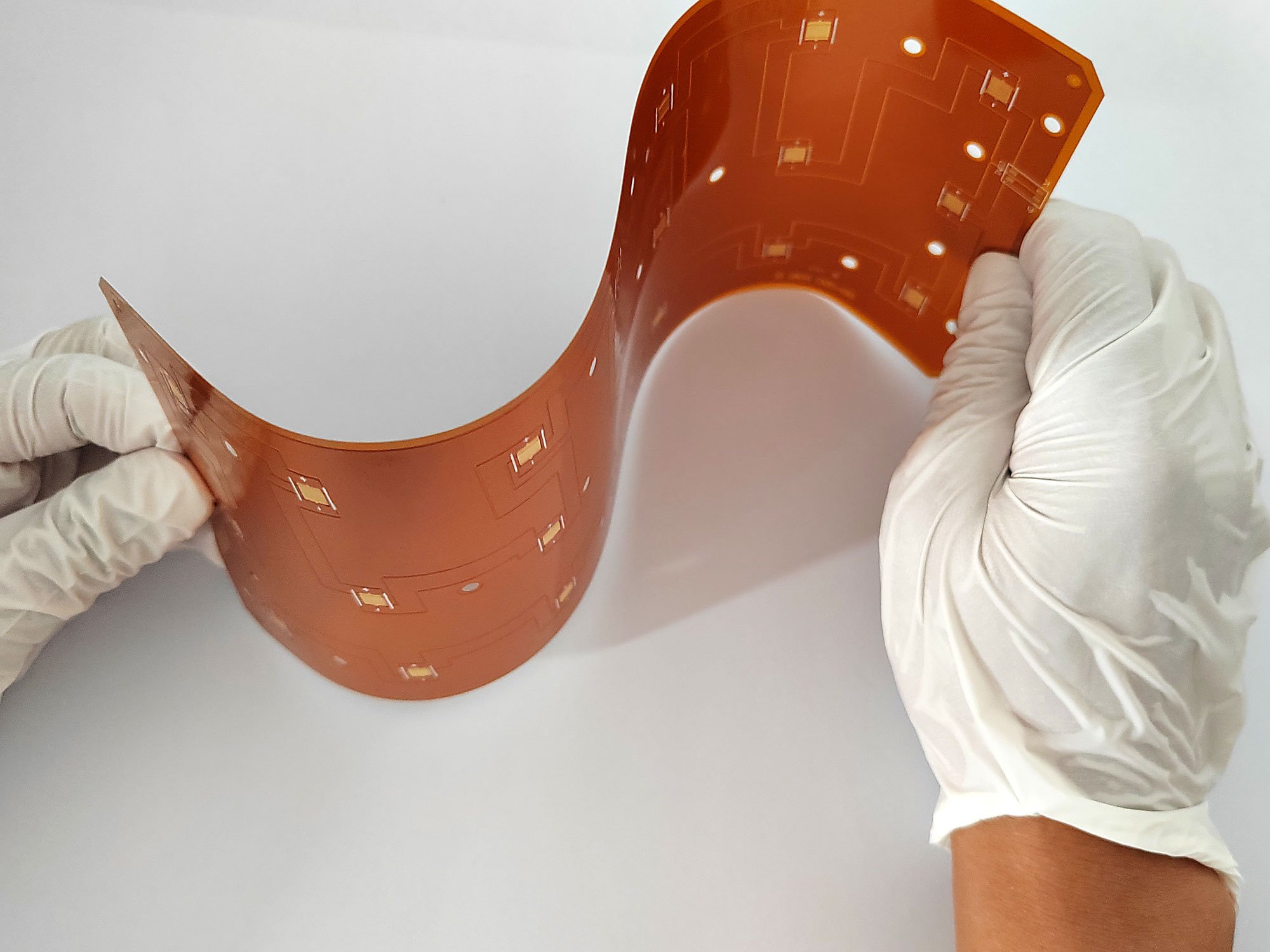

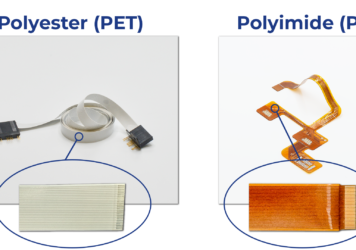

Flexible Printed Circuit (FPC) Dielectric Materials: Choosing the Best for Your Application

At PICA Manufacturing Solutions (PMS), we specialize in creating Flexible Printed Circuits (FPCs) that enable innovative designs by conforming to...

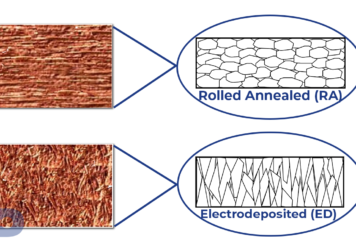

The Best Copper Conductor for Flex-to-Install & Dynamic Applications

When it comes to choosing the right conductor material for flexible printed circuits (FPC), the primary consideration revolves around how...

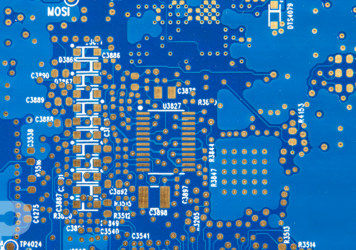

Printed Circuit Board (PCB) Via Protection: Strategies and Standards

This blog is an introduction to a larger white paper that features 7 different via protection types. Download the full white...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...