Box Build Assembly

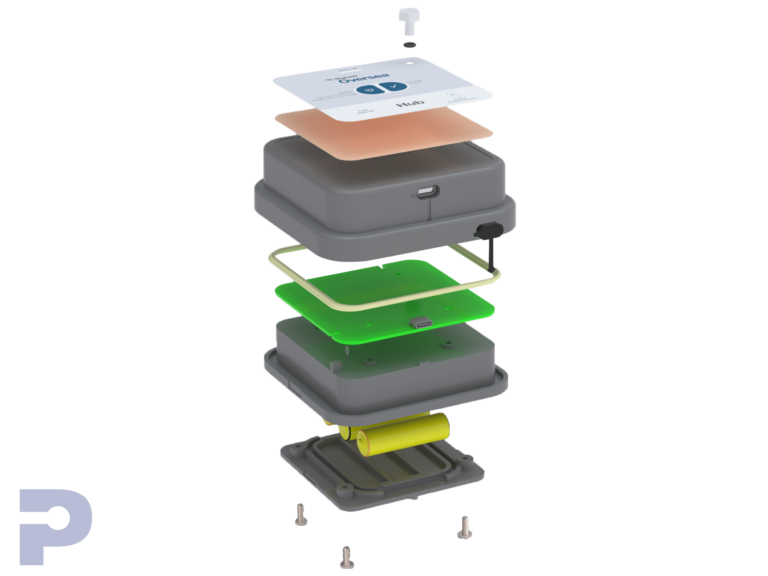

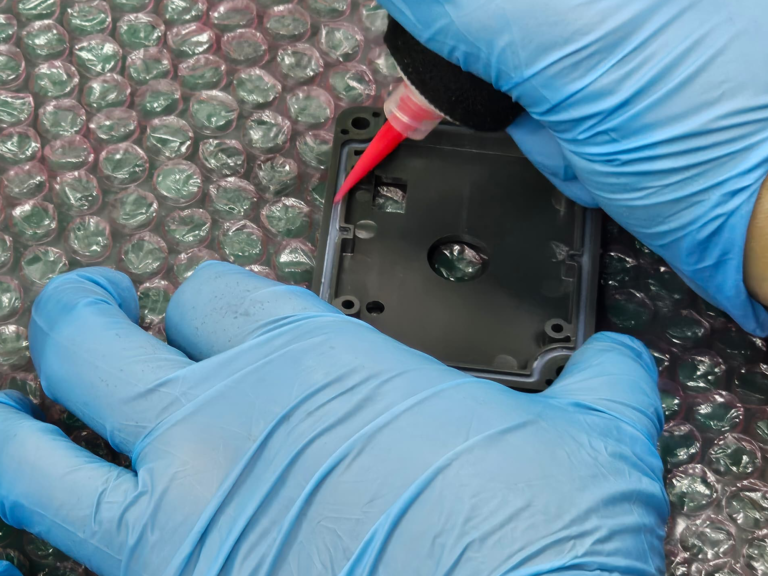

Box Build Assembly is a comprehensive manufacturing process that involves the assembly of electronic components, sub-assemblies, and essential parts into a complete, functional enclosure, or “Box.” This box build assembly can be a literal enclosure or chassis that houses all the necessary components and connections, transforming individual parts into a fully operational unit.

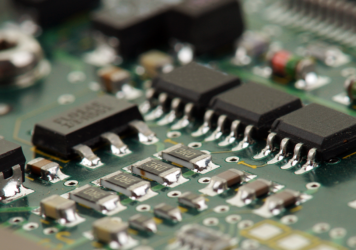

In a box build assembly, various subsystems are integrated to ensure the final product meets the desired functionality and quality standards. This process typically includes the assembly of printed circuit boards (PCBs), wiring, connectors, displays, controls, and power supplies. By incorporating each component into one cohesive assembly, box build assembly creates a ready-to-use product that can meet complex operational requirements.

The box build assembly process is not limited to hardware integration; it can also involve software installation and configuration to ensure the entire unit is functional and user-ready. This integration of hardware and software, managed within the box build assembly, provides customers with a streamlined and efficient solution for creating sophisticated electronic products.

By opting for box build assembly, companies can simplify their production processes, as they receive a completed, fully tested product that’s ready for deployment. This approach eliminates the need to coordinate multiple suppliers and assembly stages, allowing customers to focus on their core business. Whether it’s for industrial machinery, medical devices, or consumer electronics, box build assembly delivers a robust, all-encompassing solution that combines quality, reliability, and convenience.

Turnkey Solutions

Turnkey Solutions offer a comprehensive approach to manufacturing that goes beyond simple product assembly. These solutions encompass the entire manufacturing process from start to finish, managing every stage from initial design through to final delivery. With turnkey solutions, the customer can entrust the entire project to a single, reliable contractor or manufacturer, eliminating the need for multiple suppliers or intermediaries.

In a turnkey arrangement, all aspects of production are handled by one provider, who takes full responsibility for everything involved, including procurement of materials, product assembly, quality testing, and even, if needed, product design. This seamless approach to manufacturing means that turnkey solutions can streamline processes, reduce lead times, and ensure a cohesive, high-quality result.

With turnkey solutions, customers experience a hands-off approach where the manufacturer handles every detail. This means all necessary components are sourced, assembled, and tested by a single, accountable partner. By managing all phases of production, turnkey solutions simplify project management, increase efficiency, and ensure consistency across each stage, allowing customers to focus on their core business rather than the intricacies of manufacturing.

For companies looking to streamline their supply chain and ensure quality control, turnkey solutions provide a valuable option. By trusting a single manufacturer to handle everything, companies reduce the risks associated with multi-vendor projects and benefit from a more efficient, cost-effective manufacturing process. Whether it’s a complex electronics assembly or an integrated product design, turnkey solutions allow customers to bring products to market faster and with greater confidence.

Box Build Assembly Benefits

Simplified Supply Chain Management: By going to one supplier the supply chain is reduced and thus allows the OEM to focus instead on their core competencies.

Faster Time to Market: The assembly process is streamlined and done by experts and thus reducing greatly the time to market. Everyone is focused on what they are best at.

Improved Quality Control: By entrusting the assembly to experts with experience and quality systems the final product is more likely to meet high-quality standards.

Reduced Overall Costs: Due to increased expertise and efficiency the price of outsourcing the bob builds is reduced.

Turnkey Solutions Benefits

Single Point of Responsibility: The customer has one contact handling all aspects of the project, simplifying communications and coordination:

Design Expertise: Time and cost efficiencies: Turnkey providers have in-house design capabilities which can lead to better integration and optimization of the product.

Time and Cost Efficiency: The providers already have supply chain relationships allowing for faster material sourcing and reduced overall costs.

Risk Mitigation: The provider is accountable for the entire project reducing the customer’s risk in terms of product quality and delivery

Applications

Consumer electronics: Such as smartphones, tablets, home devices and gaming consoles.

Medical devices: monitoring systems, diagnostics.

Industrial equipment: Automation systems, control panels, and robotics.

Telecommunications: routers, switches, communication devices.

OEMs: want to outsource production processes of their product so they can focus on their own core competencies.

Startups and small businesses: Who have limited resources and experience.

Complex systems: Projects involving intricate electronic systems, where design, assembly, and testing need close collaboration for optimal performance.

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

Compliance: Ensuring Safety and Performance in Flexible Printed Circuit Manufacturing

When developing and manufacturing flexible printed circuits (FPCs), adhering to industry standards ensures reliability, safety, and performance. Two pivotal standards...

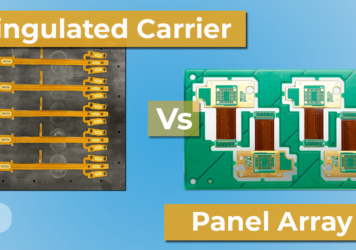

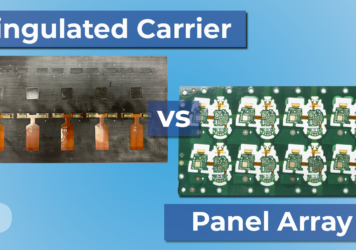

Navigating SMT Assembly Methods for Flexible Circuits Part 2

Part 2: Comparing Panel Array vs. Singulated Carrier AssemblyIn the first part of this series, we explored the key considerations...

Navigating SMT Assembly Methods for Flexible Circuits

This blog is the first in a two-part series that delves into the critical factors you need to consider when...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advance Soldering Techniques for Printed Circuit Board Assembly

Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy,...

Why X-Ray inspection is essential in flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA) processes

In the realm of flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA), X-ray inspection...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.