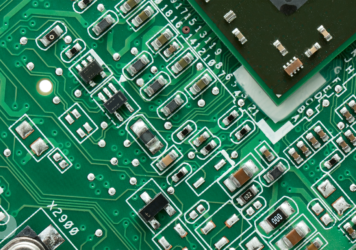

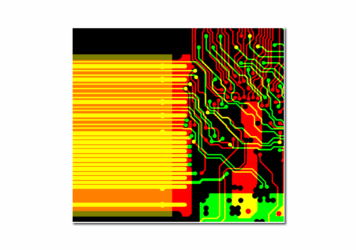

In high-frequency and high-speed electronic applications, controlled impedance in printed circuit boards (PCBs) is critical. At PICA Manufacturing Solutions, we offer comprehensive impedance control expertise to meet stringent design requirements, ensuring signal integrity and reliable performance in demanding applications.

Why Controlled Impedance Matters

Impedance control is essential for PCBs in RF, telecommunications, and high-speed digital circuits, where precise signal transmission is crucial. Impedance mismatches can lead to signal reflection, distortion, and loss, which can disrupt system functionality, especially as devices scale down and frequencies rise.

Our team collaborates closely with clients to tailor impedance control to each application, balancing performance needs with cost-effective design solutions. We address key variables, such as trace width, dielectric materials, and layer stack-ups, to maintain impedance within the target range, typically 50 ohms for single-ended traces and 100 ohms for differential pairs.

Key Aspects of Impedance Control

Trace Width and Spacing

Adjusting trace width and spacing is essential for maintaining target impedance. Our experts fine-tune these dimensions to align with material properties and design constraints, ensuring consistency across each circuit layer.Dielectric Material Selection

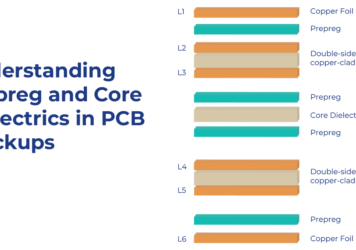

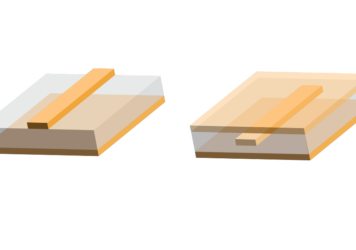

Choosing the appropriate dielectric material and thickness between layers impacts the overall impedance. At PICA, we help clients select materials based on dielectric constant and loss characteristics, tailored to the specific frequency and application requirements.Differential Impedance for Paired Signal Traces

Differential impedance, critical for high-speed and noise-sensitive applications, involves paired signal traces that carry equal and opposite signals. This setup improves noise immunity and signal integrity. We specialize in optimizing differential impedance to achieve the desired 100-ohm target, utilizing advanced design and testing methodologies.Testing and Validation

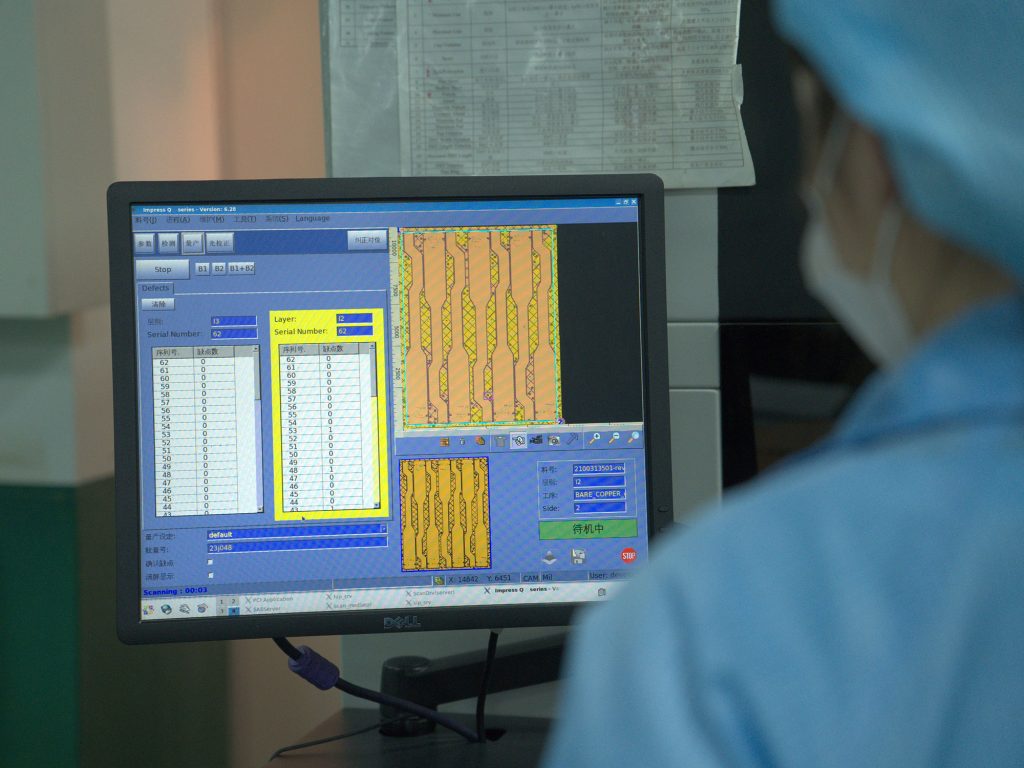

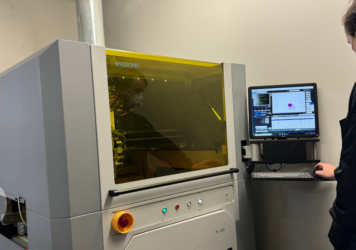

Our process includes rigorous testing of impedance characteristics using tools like time-domain reflectometry (TDR) to ensure each board meets specifications. We collaborate with clients through the entire manufacturing cycle, from design review to final testing, to ensure accuracy and reliability.

Applications of Controlled Impedance

Controlled impedance is essential in applications such as:

- Medical devices where precision signal transmission is vital for patient monitoring.

- Telecommunications requiring stable signal integrity across long-distance connections.

- Automotive and aerospace systems that depend on reliable data transmission in harsh environments.

Our Commitment to Quality

At PICA Manufacturing Solutions, we leverage cutting-edge manufacturing techniques and quality control to deliver PCBs that meet the rigorous demands of today’s high-speed applications. Our expertise in impedance control allows us to provide solutions that support both single-ended and differential signaling needs, ensuring robust and repeatable results across various applications.

For technical information on PICA’s Engineering expertise, click the button below.

Understanding Prepreg and Core Dielectrics in PCB Stackups

In multilayer PCB fabrication, what connects copper layers together isn’t just glue—it’s carefully engineered dielectric materials that control signal...

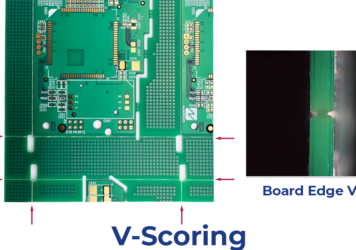

Choosing the Right PCB Separation Method: V-Scoring, Routing, and Die Cutting

Printed Circuit Board (PCB) manufacturing involves precise processes, not just in design and component assembly but also in how the...

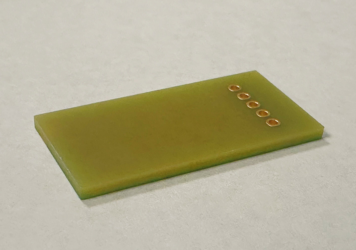

PCB Base Materials: FR-4, FR-2, CEM-1, and CEM-3

Selecting the right base material for a PCB is never a simple choice. The properties of the substrate affect everything—from...

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

Controlled Impedance in Printed Circuit Board Design

In the design of printed circuit boards (PCBs), controlling impedance is a crucial factor for ensuring optimal signal integrity, especially...

Elevating Printed Circuit Board Protection: PICA’s MYC50 Conformal Coating

PICA is excited to announce the transformation of our high-precision conformal coating capabilities. We have been integrating the

Advance Soldering Techniques for Printed Circuit Board Assembly

Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy,...

What is Differential Impedance?

In the fast-paced realm of the PCB (Printed Circuit Board) industry, achieving optimal signal integrity is crucial for the...