Enhancing Polyimide Surface Properties for Superior Bonding in Flexible Printed Circuits

Mark Pare2025-08-26T13:00:13+00:00The general scope of this article is to discuss methods for treating and characterizing the surface of Kapton, a polyimide material, to ensure effective interfacial bonding.

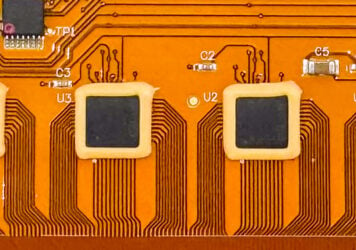

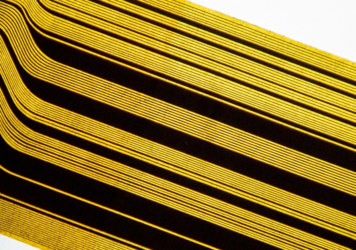

The surface of the polyimide in Flexible Printed Circuits (FPCs) undergoes various processing steps during manufacturing, which can negatively impact its surface properties. To address this, two primary strategies can be employed to rectify the issue promptly:

- Physical abrasion of the surface to an appropriate level using the Hyoki process or a similar method. This technique removes contaminants and increases the surface area to allow for consistent bonding.

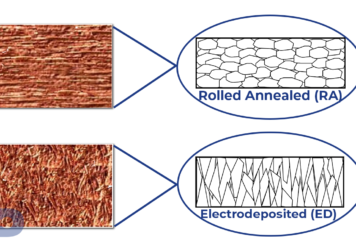

- A chemical modification approach involves using an etchant made of alkyl hydroxide components to remove the outer layer of the Kapton polyimide. This process relies on the reaction between PMDA/ODA and NaOH to form a polyimide monomer (potassium salt of polyamic acid), which is then protonated with HCl to produce polyamic acid. The introduction of a functional –OH group through this reaction enhances wettability and adhesion for various adhesives, effectively preparing the Kapton polyimide surface. This method has been successfully used for years to create a hydrophilic surface with a surface energy of 60 to 70 dynes per centimeter.

Hyoki Process Summary: The Hyoki process is deemed the more practical solution due to its simplicity and direct application to surface preparation. Comparable to sandblasting, this method uses an abrasive media in a high-pressure water stream to achieve a non-directional, matte finish with variable roughness, depending on the chosen media and settings. Effective control of the parameters and allowing the surface to be adequately roughened are crucial for success. When a surface is abraded, it exposes a new layer and increases the surface area due to mechanical deformation, generally improving the surface’s bonding performance.

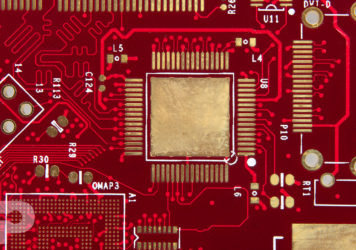

PICAKit Flex Samples

Experience the tactile qualities of FPCs (flexible printed circuits)—thickness, flexibility, bendability, and foldability.

The PICAkit offers a diverse array of samples, each showcasing different constructions and material thicknesses.

From PICA’s experience, Kapton polyimide films, such as the H-film from DuPont, typically have a surface energy of 45 to 50 dynes per centimeter, with E-type polymers being lower. This is not ideal for most adhesive applications, as the surface energy of the bonding adhesive should be significantly higher than that of the Kapton substrate for optimal wettability. The surface energy of the substrate may need to be increased by up to 25% to accommodate traditional structural adhesives. The Zismen equation offers an empirical relationship between the liquid’s contact angle and the difference in surface free energies of the substrate and the liquid.

For effective bonding, the FPC should have a translucent appearance post-processing, indicating the surface has been sufficiently roughened. A smooth or glass-like finish indicates inadequate processing and necessitates individual surface energy measurements for each part.

In summary, the bonding adhesive must wet the Kapton surface, requiring the surface energy of the adhesive to be as low as or lower than that of the substrate to ensure effective bonding.

Contact us with any questions regarding polymide in Flexible Printed Circuits.