Roll-to-Roll Processing: Driving the Next Generation of Flexible Circuits

Simon Lim2025-10-28T19:50:24+00:00Electronics are shrinking, getting lighter, and expected to perform flawlessly in demanding environments. From medical wearables to industrial sensors and consumer devices, the push for smaller and smarter products is fueling new approaches in manufacturing. One breakthrough is roll-to-roll (RTR) processing, a continuous method that’s reshaping how high-density flexible circuits are built.

From Panels to Continuous Flow

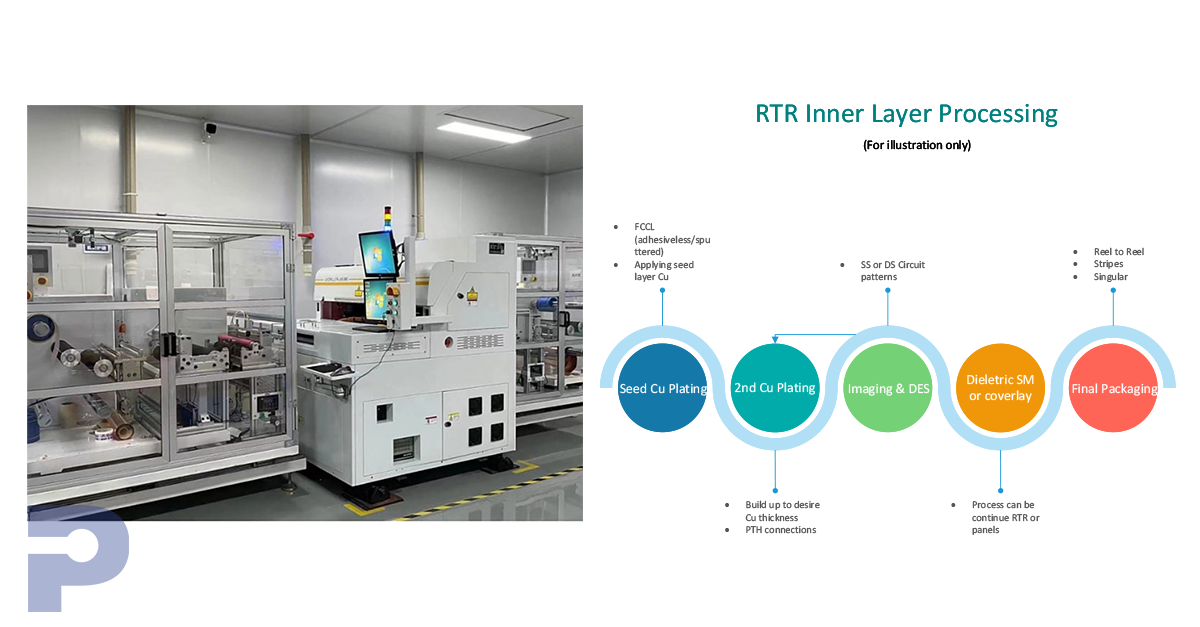

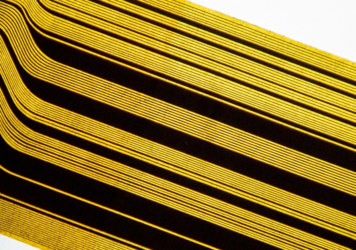

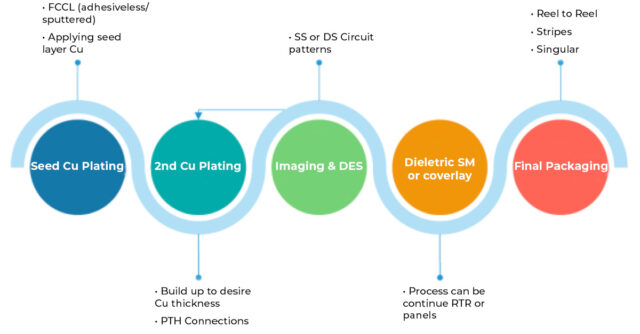

Unlike traditional panel-based PCB production, RTR keeps flexible substrates moving through imaging, plating, drilling, and finishing without ever breaking the roll. The result is a faster, cleaner, and more consistent process that reduces waste and keeps quality under tight control.

Where RTR Makes the Biggest Impact

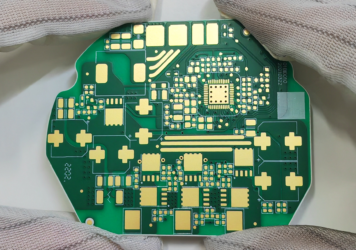

RTR technology shines in applications where miniaturization and reliability are non-negotiable. It supports ultra-fine features and advanced assembly techniques used in:

• MEMS and sensor packaging

• FCOS, COF, TAB packaging

• Medical electronics and wearables

• High-volume consumer devices

• Imaging and industrial systems

The Payoff: Speed, Precision, and Flexibility

Manufacturers choose RTR because it delivers:

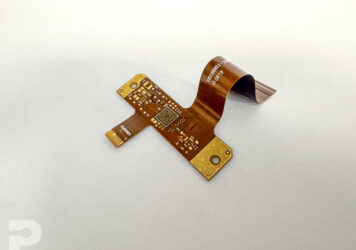

• High throughput for cost-effective, large-scale builds

• Thin FCCL (adhesiveless/sputtering) substrates

• Fine line capability down to 15/15 µm with ±10% conductor control (SAP & mSAP subjected to thickness of Cu)

• Laser-drilled vias as small as 25 µm

• Delivery options in roll form, tape & reel, or singulated parts

• Inspection and traceability that meet strict medical and industrial IPC standards

Ready to push your designs further?

Explore how PICA’s Roll-to-Roll flexible circuit processing delivers speed, precision, and scalability for your next project.

Challenges to Keep in Mind

RTR requires specialized lines and is typically limited to 250 mm web widths and 100m long roll. There are customs-built lines that can do up to 500mm web width but rare as the dimension stability control will be challenging. Most panels processing manufacturers are now converting their inner layer processing into RTR for better yield control. Some designs may need rethinking from panel-based layouts, and certain finishes are still better suited for panel processing. Even so, for high-density and high-volume flexible circuits, the efficiency gains outweigh these limitations.

Why PICA is Investing in RTR

At PICA Manufacturing Solutions, our RTR systems are built for precision and scalability. We pair advanced imaging, plating, and laser-drilling capabilities with 100% inspection and full unit-level traceability. Whether delivered on a roll, in tape & reel, or as singulated parts, our RTR circuits help customers bring innovative electronics to market with confidence.

RTR Inner Layer Processing

Discover how roll-to-roll processing can accelerate your next design. Visit us at

https://www.picamfg.com.