Choosing the Right Stiffener: A Guide to Materials for Flexible Circuit Support

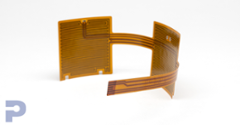

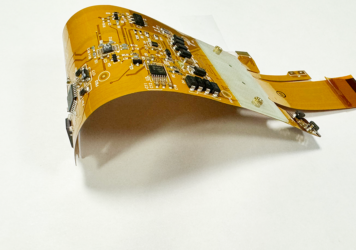

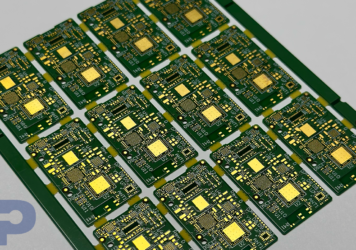

FlexPros2025-08-26T14:35:06+00:00Stiffeners are essential for providing mechanical support to flexible circuits, particularly in areas where electronic components are mounted. By reinforcing specific sections of the flex circuit, stiffeners prevent excessive bending and maintain the circuit’s structural integrity. This is crucial for ensuring reliable electrical connections and operational stability.

Types of Stiffener Materials

Stiffeners come in a variety of materials, each chosen for its properties and the specific requirements of the application. Here’s a closer look at the most commonly used materials:

- Polyimide and Polyester Films:

- These films are popular choices for flexible circuit stiffeners due to their flexibility and durability. Commonly available in a thickness of 0.125 mm (0.005”), these materials are excellent for general reinforcement, particularly under component mounting areas.

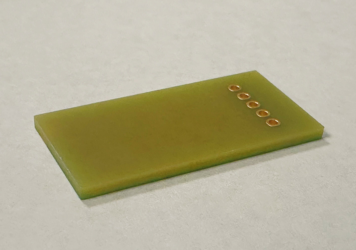

- Fiberglass Laminates (FR4, G10, FR5):

- Fiberglass laminates are favored for their high mechanical strength and good electrical properties, coupled with cost-effectiveness. FR4, the most commonly used type, is flame retardant, thanks to its epoxy resin composition. G10 and FR5 offer variations in flame retardancy and temperature resistance, providing options for more demanding environments. These materials can vary in thickness from 0.125 mm to 3.175 mm (0.005” to 0.125”), allowing for versatile application across different types of flex circuits.

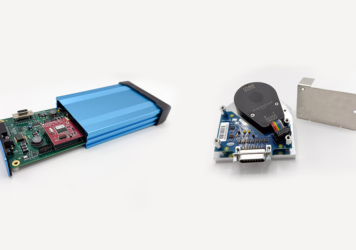

- Metal Stiffeners (Aluminum or Steel):

- Metal stiffeners are chosen for applications that require forming, such as when a flex circuit needs to maintain a specific angle at a fold. Metals like aluminum or steel can be used as thin as 0.125 mm (0.005”) and are capable of being bent to precise angles, which is not possible with polyimide and polyester stiffeners.

- Plastic:

- Plastic stiffeners are used when additional features, such as positioning elements for other components, are needed. Their versatility in manufacturing allows them to be custom shaped to meet specific design requirements, which can include 3D configurations.

Want to learn more about our Flexible Circuit design capabilities? Click below.

Applications and Considerations

Choosing the right stiffener material involves considering several factors, such as the environmental conditions the circuit will face, the mechanical demands of the application, and the electrical properties required. Each material offers distinct advantages, and the choice depends on the balance of cost, performance, and physical properties needed.

In conclusion, stiffeners are vital components that enhance the performance and durability of flexible circuits. Whether it’s maintaining the shape of the circuit, supporting component mounting, or adding functional features, stiffeners provide the necessary reinforcement to meet the diverse needs of modern electronic devices. Their correct application ensures that flexible circuits can deliver optimal performance in even the most challenging applications.

Contact us for more information on stiffeners.