Flexible Printed Circuit (FPC) Dielectric Materials: Choosing the Best for Your Application

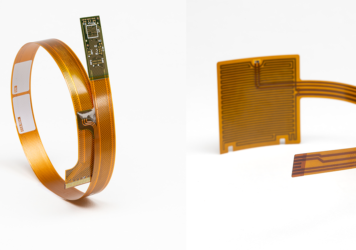

Mark Pare2025-08-26T13:39:53+00:00At PICA Manufacturing Solutions (PMS), we specialize in creating Flexible Printed Circuits (FPCs) that enable innovative designs by conforming to limited spaces and unique shapes. The choice of dielectric material, which serves as the insulation layer in these circuits, is crucial not only for their electrical performance but also for their durability and adaptability to various environments. In this article, we delve into the properties of dielectric materials used in FPCs, focusing on their characteristics and application suitability.

Desirable Characteristics of FPC Dielectrics

We at PICA guide our selection of dielectric materials for FPCs by a set of desirable characteristics that ensure the circuits meet the required performance and reliability standards:

Flexibility: Essential for materials used in applications where bending and flexing are routine.

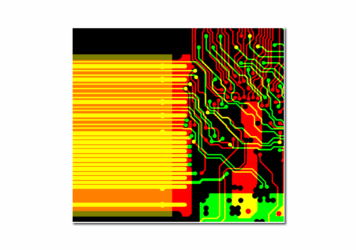

Electrical Properties: Includes considerations like dielectric constant, loss tangent, and insulation resistance, which affect signal integrity and insulation effectiveness.

Dimensional Stability: Important for maintaining the shape and size of the circuit under mechanical stress and temperature changes.

Tear and Thermal Resistance: These properties are crucial for applications involving mechanical wear and high temperatures.

Chemical Resistance: Ensures the material can withstand harsh environments without degrading.

Thermal Stability: The dielectric material should withstand high temperatures during soldering and operation without deforming, delaminating, or losing electrical properties.

Low Dielectric Loss: Vital for minimizing signal attenuation and ensuring reliable signal transmission, particularly in high-speed or high-frequency applications.

Electrical Insulation: Must provide effective insulation between conductive traces to prevent short circuits and signal interference, with a high breakdown voltage to handle operating voltages.

Adhesion: Excellent adhesion to copper conductors and other layers in the FPC structure is essential to prevent delamination and ensure reliable electrical connections.

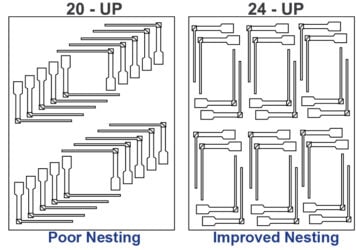

Compatibility with Manufacturing Processes: The material should be compatible with standard FPC manufacturing processes, including etching, solder mask application, and lamination.

Lot to Lot Consistency: Critical for maintaining performance standards across different production runs.

Cost: Always a consideration, balancing performance with budget constraints.

Enhance your flexible printed circuits with high-performance dielectric materials designed for durability and reliability. Explore our premium selection and take your designs to the next level.

Key Dielectrics in FPC Applications

At PICA, we use several materials as dielectrics in our FPCs, each offering different benefits and challenges:

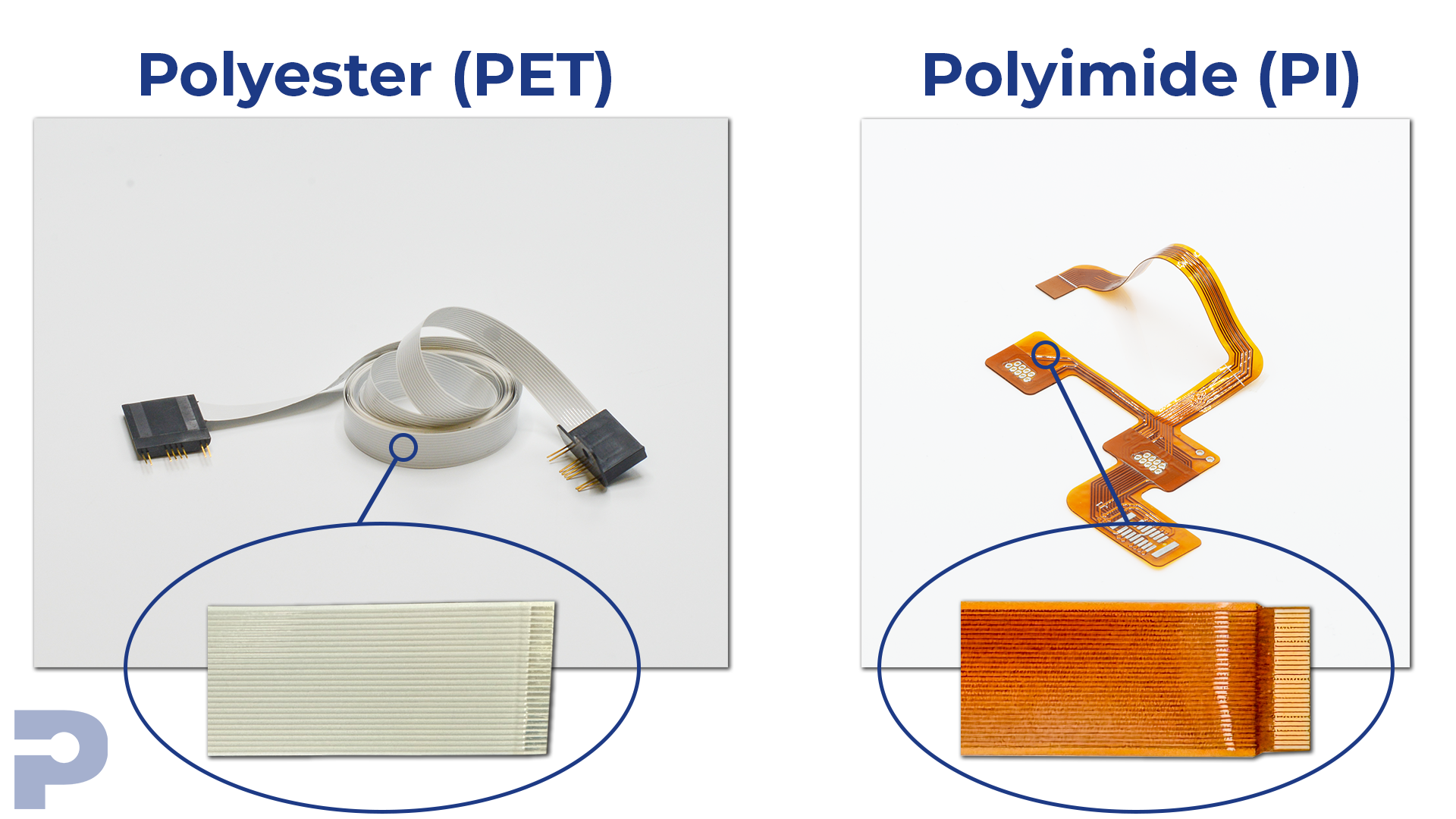

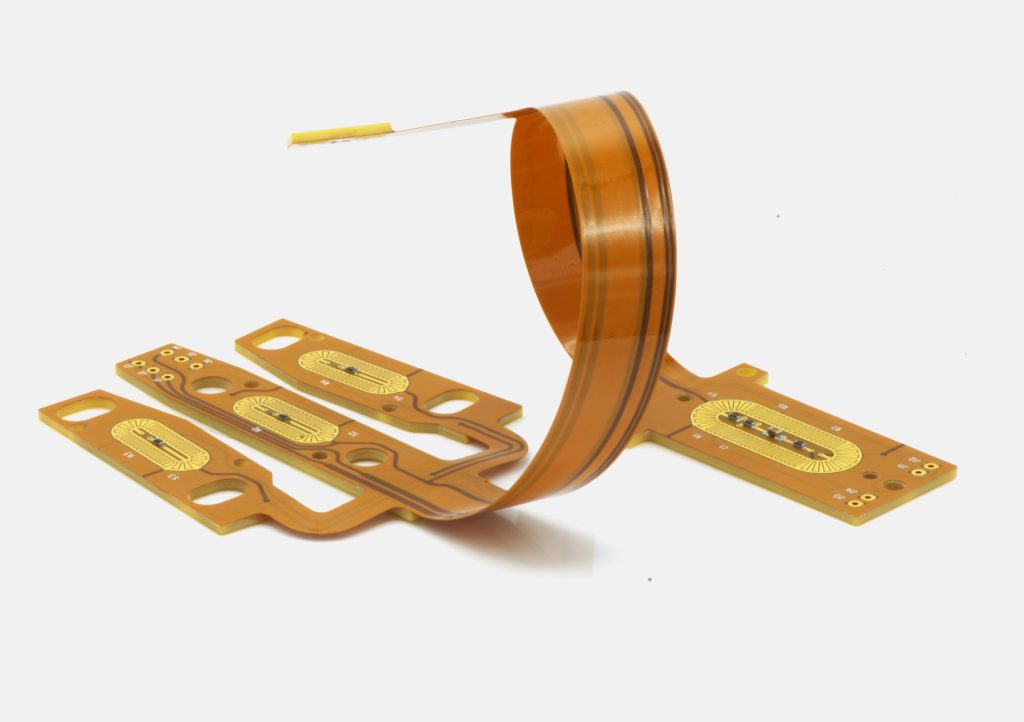

Polyimide (PI): This is the most popular choice due to its exceptional flexibility and high tensile strength across a broad temperature range. Polyimide films, ranging in thickness from 12 µm to 125 µm, are nonflammable, halogen-free, and exhibit excellent resistance to extreme soldering conditions without a loss of electrical properties.

Polyester (PET): Known for its good mechanical properties and lower cost compared to polyimide. However, it does not perform as well at high temperatures, which limits its use in some high-end applications.

Liquid Crystal Polymer (LCP): Offers very good thermal and chemical resistance, and it is used in applications where dimensional stability and low moisture absorption are critical.

Polyimide/Teflon (PTFE): A composite material that combines the excellent thermal and chemical resistance of Teflon with the mechanical and electrical properties of polyimide. This blend is particularly suitable for high-frequency applications due to its low dielectric constant and loss tangent.

Factors Influencing the Choice of Dielectric

Choosing the right dielectric material for an FPC involves considering the operating environment and the specific requirements of the application, a process where we excel at PICA. For instance, devices that operate under high mechanical stress or in chemically reactive environments might require materials like LCP or polyimide/Teflon composites, whereas consumer electronics, which are less exposed to harsh conditions, might use polyester due to its cost-effectiveness.

Conclusion

At PICA Manufacturing Solutions, the selection of dielectric materials for flexible printed circuits is a critical decision that influences the performance, durability, and cost-efficiency of electronic devices. Materials like polyimide stand out for their robustness and versatility, but the final choice must align with specific application needs and environmental conditions. By carefully assessing the desired characteristics and constraints, we optimize our FPC designs to meet both current and future challenges in the electronics industry.

Contact us with any questions on choosing FPC Dielectric materials.