Ensuring the Integrity of Printed Circuit Boards (PCB): The Vital Role of Surface Cleanliness.

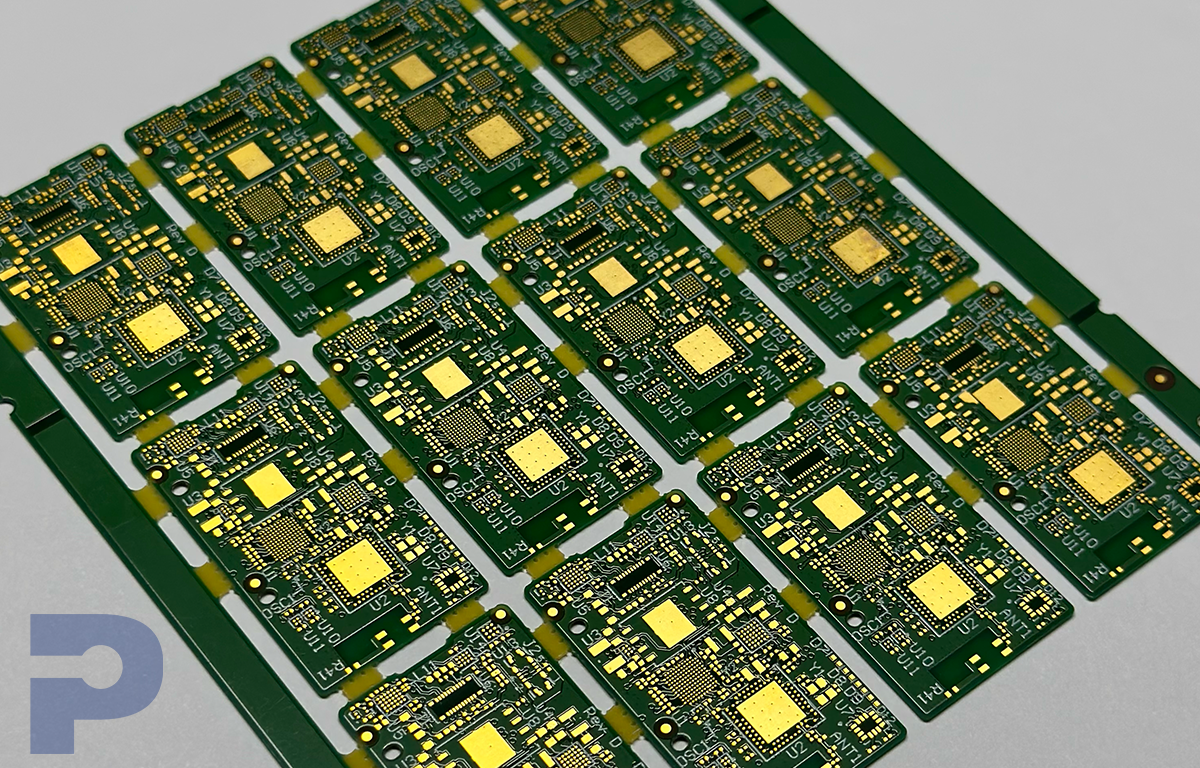

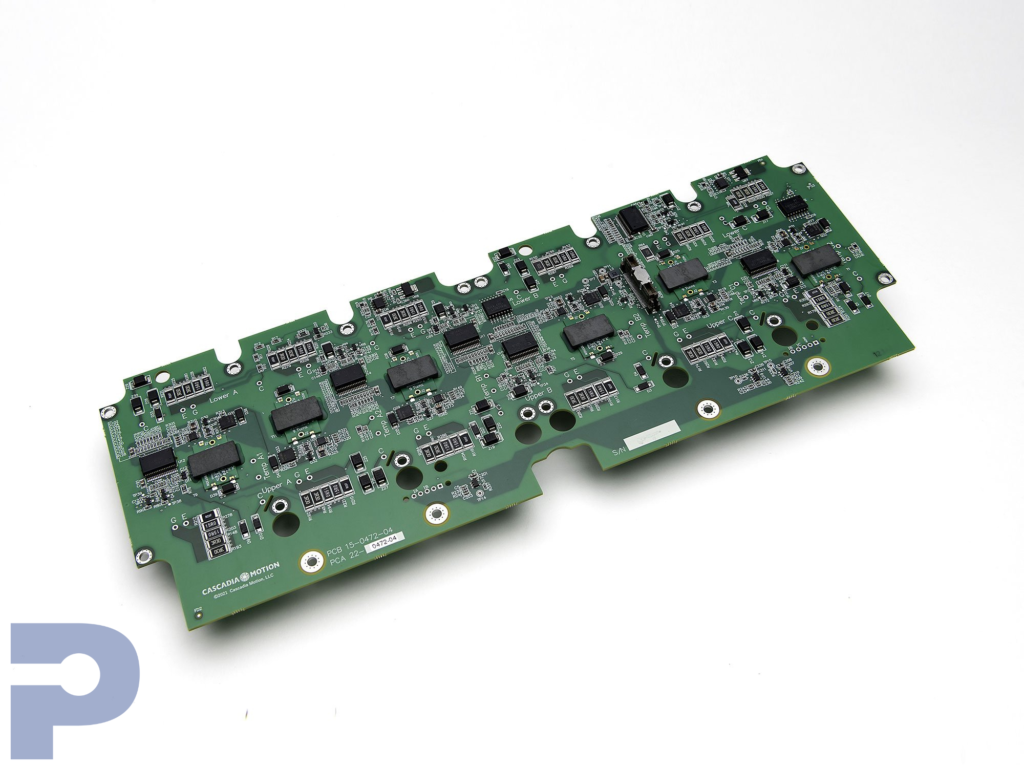

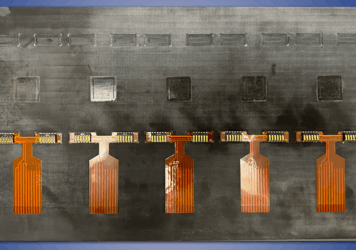

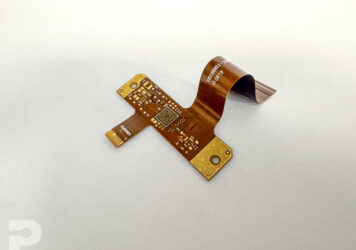

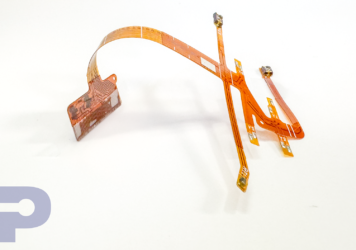

Simon Lim2025-08-26T12:49:32+00:00The production of Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs) encompasses chemical, mechanical, and printing processes that often result in the accumulation of unwanted residues on their surfaces. The presence of even minuscule contaminants can significantly affect the functionality, performance, and reliability of the final products. Recognizing the paramount importance of surface cleanliness, PICA has consistently focused on testing surface contamination. This move underscores a wider dedication within the industry to meet the rigorous cleanliness standards demanded by contemporary applications.

Ionic vs. Non-Ionic Contamination: A Delicate Balance

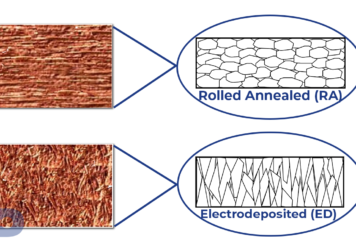

Contaminants on the surface of PCBs can be broadly classified into two categories: ionic and non-ionic. Each has distinct sources and impacts on circuit behavior, necessitating tailored approaches for mitigation.

Ionic Residues: Conductive Threats

Ionic residues are particularly insidious due to their conductive nature when dissolved. Moisture, ever-present in most environments, can trigger these residues to disassociate into charged species, thereby increasing the solution’s conductivity. Common culprits behind ionic contamination include:

- Plating chemistries

- Flux activators

- Perspiration

- Ionic surfactants

- Ethanolamines

These substances can originate from various stages of the PCB manufacturing and handling processes. The risk they pose is not trivial; increased conductivity can lead to current leakage, fostering conditions for dendrite growth or accelerating corrosion—all of which compromise the integrity and lifespan of the circuit.

Stay ahead in PCB design and manufacturing! Dive into our expert blog posts on rigid PCBs to learn about the latest trends, best practices, and key insights. Explore now and keep your projects on track

Non-Ionic Residues: Organic Obstacles

On the other end of the spectrum, non-ionic residues don’t conduct electricity but can still degrade PCB performance. Typically organic, these substances include rosin, oils, and grease that may linger after fabrication or assembly. While they don’t directly enhance conductivity, their presence can interfere with component placement, soldering quality, and overall circuit cleanliness.

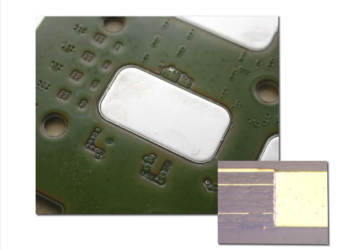

The ROSE Method: A Measure of Purity

To combat these challenges, assessing the level of ionic contamination is paramount. The Resistivity of Solvent Extract (ROSE) method offers a proven approach. By evaluating how a solution’s resistivity changes with ion concentration, it provides a quantitative measure of contamination. The principle is straightforward: as ion levels increase, resistivity drops, indicating a higher degree of contamination.

PICA’s Proactive Stance

Understanding these dynamics, PICA has instituted a robust protocol for monitoring ionic contamination. By conducting periodic assessments of their printed circuit boards and flex circuits—before and after assembly—they can identify and mitigate potential issues early in the production cycle. This vigilance, coupled with strict process controls, ensures that PICA’s products meet the highest cleanliness standards demanded by customers.

Contact us for more information on PCBs.