Preventing the Delamination of Your Flex Circuitry in the Soldering Reflow Process

Mark Pare2025-07-24T15:23:16+00:00Why Do Flex PCB Delaminate in High Temperature Exposure?

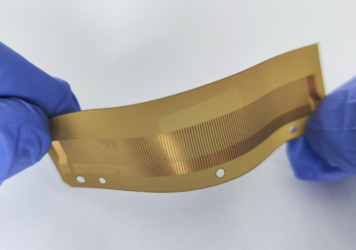

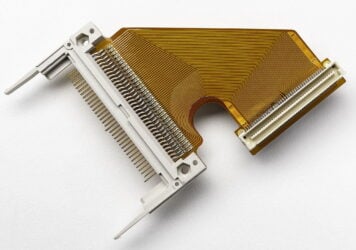

Flex Printed Circuits (FPCs) face a common issue during soldering reflow: delamination. This problem, primarily caused by rapid temperature changes, can severely impact the circuit’s integrity and functionality. The root cause is often moisture absorption, which can occur in various parts of the FPC, leading to separation of layers upon exposure to high soldering temperatures.

Common Moisture Absorption Points

Moisture absorption can compromise several types of FPC constructions, including:

- Adhesive-based structures: where adhesives are used to bond layers together.

- Outer covers: such as adhesively bonded polyimide covercoats, films, and liquid solder masks, especially in single and double-sided adhesiveless laminates

- Externally bonded stiffeners: which provide mechanical support to the circuit.

- Multilayer constructions: involving three or more layers, where moisture can get trapped between layers.

- Rigid-flex PCB: which combine flexible and rigid elements, potentially complicating moisture expulsion.

Innovative Solutions to Mitigate Moisture Impact

To counteract the delamination risk, adopting innovative design modifications and processing techniques is essential. These include:

- Designing for Moisture Escape: Altering circuit layouts to include channels that facilitate moisture escape, reducing the risk of delamination.

- Adding Outer Surface Ports: Incorporating openings and holes at strategic locations to shorten moisture travel paths, enhancing drying effectiveness.

- Optimized Baking Protocols: Baking Flex Printed Circuits at specific temperatures and durations based on their construction type and thickness. This step is crucial for removing absorbed moisture without damaging the circuits.

Do you have more questions about Flex Circuitry delamination? Contact us today and speak to an engineer.

Detailed Baking Recommendations

For effective moisture removal, it’s recommended to bake FPCs as follows:

- Single & Double-Sided Circuits: 2 to 3 hours at 105 to 115°C.

- Three-Layer Polyimide Circuits: 3 to 4 hours at 105 to 115°C.

- Four Layers and Above: At least 4 hours at 105 to 115°C.

- Rigid-Flex PCB: The baking time increases with thickness, ranging from 2 hours for up to 1.0 mm thickness to 6 hours for 1.8 to 4.0 mm thickness.

Post-Baking Handling and Storage Guidelines

After baking, it’s crucial to handle and store FPCs carefully to maintain their integrity:

- Avoid storing FPCs in environments exceeding 50% relative humidity for more than 8 hours post-baking.

- Employ vacuum storage or keep the circuits in an oven at 35°C, preferably in sealed bags with desiccant to absorb residual moisture.

Considerations for Solderability

Baking can affect solderability, especially for finishes like Immersion Tin, Immersion Silver, and OSP, which are less resistant to oxidation than solder or ENIG finishes. Utilizing vacuum baking at lower temperatures can help mitigate these solderability issues, preserving the circuit’s quality and ensuring robust performance.

Conclusion

Delamination in Flex Printed Circuits due to moisture absorption is a significant concern, but with careful design, processing, and storage practices, its risks can be effectively managed. By adopting the strategies outlined above, PICA Manufacturing Solutions can enhance the reliability and durability of your Flex Printed Circuits, ensuring they meet the demands of your applications.

Contact us with any questions about preventing the delamination of flex circuitry in the soldering reflow process.