Roll-to-Roll (R2R) Process for Flexible Printed Circuits

Continuous, High-Throughput Flex Circuit Manufacturing for High-Volume Applications

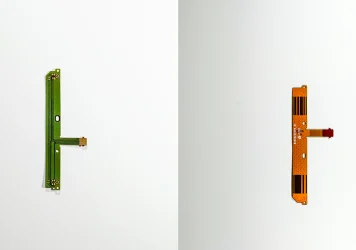

The roll-to-roll (R2R) process enables flexible circuits to be manufactured in a continuous web format, delivering outstanding throughput, quality and cost-efficiency. PICA’s R2R technology supports long-length, high-volume production of flexible PCBs, wearables, sensor ribbons, and printed electronics with tight tolerances and reliability.

Why Choose Roll-to-Roll (R2R) Process?

- High Production Throughput & Scalability – Continuous unwinding, processing and rewinding eliminates the start-/stop of panel processing and enables higher volume output.

- Lower Cost Per Unit for Flexible Circuits – Web-based processing reduces waste and handling, lowering manufacturing cost for large-volume runs.

- Exceptional Uniformity & Precision – Tight web tension control, alignment guides and continuous flow maintain high dimensional and process consistency.

- Ideal for Length, Flexibility & Compact Form-Factors – Enables long runs of flexible circuits (ribbon, roll, tape) with minimal seams, less interconnect complexity.

- Optimized for Modern Applications – Wearables, IoT ribbons, medical sensors, large-area flexible electronics benefit from R2R’s continuous nature.

Roll-to-Roll (R2R) Capabilities – Highlights

- Web processing for flex circuits: imaging, plating, etching, drilling and finishing conducted while substrate remains on roll.

- Tight process controls: web tension, alignment guides, unwind/rewind speed control, profile flatness.

- Fine-line routing and substrate usage compatible with long web formats; support for tape-&-reel or singulated output from roll form.

- Engineering support for roll-to-roll vs panel trade-offs, substrate selection, handling of long runs, and volume manufacturability.

Global Design & Manufacturing Support

PICA provides end-to-end support for roll-to-roll flexible circuit programs — from early design consultation and stack-up definition, through pilot R2R runs and high-volume production. Our global footprint ensures scalable supply, continuous process control, and full traceability for roll-based flexible circuit manufacturing.

Benefits of Roll-to-Roll Process

Continuous Flow = Higher Output

By eliminating discrete panel transitions, R2R processes boost throughput and make high-volume flexible circuit builds cost-effective.

Consistent Quality Across the Web

Continuous motion and advanced tension/alignment controls ensure each unit from the roll meets the same high standard.

Simplified, Streamlined Interconnects

Roll-based flex circuits reduce the need for segmentation, joining or wiring harnesses — simplifying assembly and improving reliability.

Cost-Efficient for High Volumes

Web-based production reduces waste, handling and cycle time — delivering lower cost per unit when scale matters.

Design Flexibility for Modern Products

R2R supports long-run, high-density, flexible circuits in wearable, medical, industrial and IoT systems with tight form factors and high production volumes.

Markets We Serve with Roll-to-Roll Process

Wearables & IoT Devices

Production of ultra-thin, flexible ribbons and interconnects that need continuous manufacture and high volume.

Medical & Diagnostic Equipment

Long-length sensor ribbons, disposable flex strips, high-volume assemblies benefit from roll manufacturing.

Consumer Electronics & Flexible Displays

Flexible display ribbons, rollable modules, large-area flexible circuits suit R2R format.

Industrial & Automation Systems

Flexible sensor arrays, ribbon cabling, conveyor‐mounted electronics where length, flexibility and volume matter.

Embedded & Printed Electronics

Emerging printed-electronics applications (flex sensors, IoT ribbons, smart packaging) leverage R2R for cost-effective scaling.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Flex PCB Substrate Deep Dives Beyond Polyimide

PET vs PEN, LCP, PTFE/fluoropolymers, and specialty films like PEI/PEEK: when each wins, where each struggles, and what it means...

Highlights from MD&M WEST 2026

MD&M West 2026 in Anaheim brought together medtech, automation, design/manufacturing, plastics, and packaging, so the biggest trend wasn’t one...

Tariffs in the United States: History, Reality, and How PICA Helps You Navigate Them

Tariffs have played a role in the U.S. economy since the nation’s founding. In the early days of the republic,...

CES 2026 Highlights: The Breakthrough Technologies Powered by Advanced Flex & PCB Design

Las Vegas, January 2026 — CES 2026 once again confirmed that the pace of innovation in consumer tech, mobility,...

What Is Box Build Assembly? Process, Benefits & How to Choose a Manufacturer

Box build assembly—sometimes called systems integration—involves assembling a complete electronic product by combining a finished PCBA with...

Designing PCBs for Medical Devices: Key Considerations & Compliance Tips

PCB design for medical electronics demands more than just electrical functionality. Devices must meet...

What to Look for in a Manufacturing Company in Malaysia

When evaluating a manufacturing company in Malaysia, most teams are focused on a few essentials: capability fit, reliable quality systems,...

LPI Solder Mask vs. Polyimide Coverlay: Choosing the Right Protection for Flexible Circuits

Protecting the copper circuitry on a flexible printed circuit (FPC) is essential to ensuring long-term reliability and...