EMI and Electromagnetic Interference Shielding Solutions

Protecting Electronics from Noise, Interference and Compliance Risk

Electromagnetic interference is a growing concern in today’s dense circuitry and high-speed devices. PICA provides comprehensive EMI shielding solutions that integrate directly into board architecture. Our approach combines shielding materials, stack-up engineering, via-fence strategies, grounding planes, conductive coatings, and modeling support to help you meet signal integrity, EMC and compliance targets while maintaining cost-effective manufacturability.

Why Choose EMI Shielding Solutions?

• Signal Integrity and Performance Protection

Shielding limits coupling, crosstalk and radiated emissions that reduce margin on high-speed, RF and mixed-signal circuits.

• Regulatory and EMC Compliance

Optimized shielding helps designs pass CE, FCC, IEC, automotive EMC and other global compliance standards.

• Versatile Shielding Materials and Methods

We apply copper foils, conductive films, sprayed or plated coatings, shielding cans and via-fence isolation tailored to the design requirements.

• Design for Manufacturability Integration

Shielding is engineered into the stack-up and routing alongside impedance control, bend-to-install requirements and assembly constraints so performance and reliability are maintained.

• Greater Reliability in Harsh Environments

Shielded designs withstand heavy EMI exposure found in industrial, automotive, aerospace and radar systems while maintaining long service life.

EMI Shielding Capabilities – Highlights

• Embedded shielding layers and via-fence isolation for planar containment and reduced radiated fields in flex, rigid and rigid-flex circuits.

• Conductive coatings and shielding films for flexible or ultra-thin boards that require tight bend radii, dynamic flex performance or small enclosures.

• Shielding can or metal case integration for high-emission modules like RF amplifiers, switching power stages and radio transceivers.

• Stack-up, ground segmentation and impedance modeling to ensure shielding does not degrade controlled impedance lines, return paths or signal rise time performance.

• Prototype to volume manufacturing support including yield optimization, shielding layer adhesion, via-fill integrity, and cost-efficient material and coating selection.

For more technical information on PICA’s Engineering expertise, click the button below.

Global Design and Manufacturing Support

PICA supports EMI shielding from concept through production. Our engineering team works directly with your designers to define the shielding approach, select materials, model field behavior, integrate shielding layers into the stack-up, validate grounding strategies and ensure the design remains manufacturable. We review shielding effectiveness as part of the board architecture, routing, coating processes and assembly.

Benefits of EMI Shielding Solutions

Cleaner, More Reliable Signals

Effective shielding supports stable high-speed and RF performance, reducing data errors and signal distortion.

Fewer Compliance Delays

Shielded architectures reduce EMC test failures and costly redesigns, helping products reach markets faster.

Smaller, Denser Designs

Shielding for flex, rigid-flex and compact PCBs enables tight layouts without increasing emissions or noise susceptibility.

Robustness in Challenging Environments

Shielded boards maintain performance in vibration, heavy switching environments, power density zones and strong electromagnetic fields.

Manufacturable and Cost-Effective

Because shielding is integrated early and aligned with stack-up, plating, coating and assembly flows, you achieve protection without excess cost or complexity.

Markets We Serve with EMI Shielding Solutions

Consumer and Mobile Electronics

Wearables, IoT and handheld devices require strong RF and wireless shielding for performance and battery life.

Medical Devices

Imaging systems, sensors and patient-worn electronics demand EMI control for safety and diagnostic accuracy.

Automotive and Transportation

ADAS, EV power electronics and infotainment systems must perform in noisy, high-voltage and high-switching environments.

Industrial and Communications Systems

Automation, 5G systems, radar, base stations and telecom equipment depend on EMI resilience for network integrity.

Aerospace, Defense and Rugged Electronics

Mission critical platforms require precise shielding and high reliability in extreme EMI conditions.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

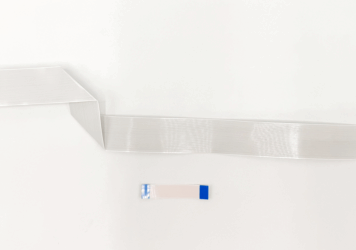

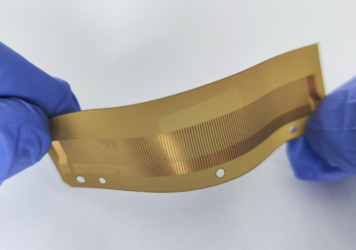

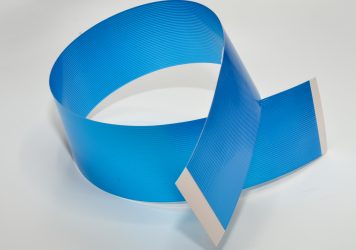

Flat Flexible Cables (FFC): A Cost-Effective and Scalable Interconnect Solution

For engineers balancing performance, flexibility, and cost, Flat Flexible Cables (FFC) remain one of the most efficient...

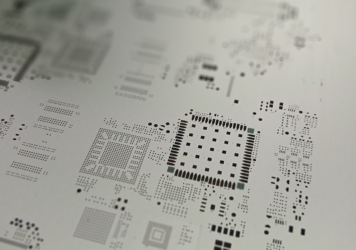

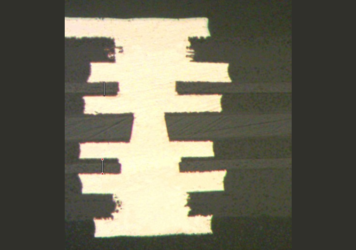

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

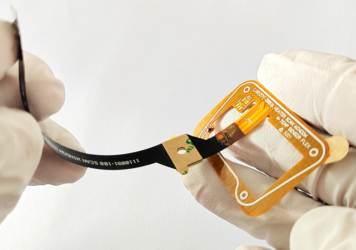

Understanding Flexible Printed Circuit (FPC) Cost Drivers

Flexible Printed Circuits (FPCs) are essential components in modern electronics, enabling lightweight, compact, and high-performance designs. However, they come...

Common Mistakes Made by PCB Designers When Designing Flexible Circuits (FPCs)

Flexible Printed Circuits (FPCs) are widely used due to their lightweight, flexible, and compact nature, making them ideal for...

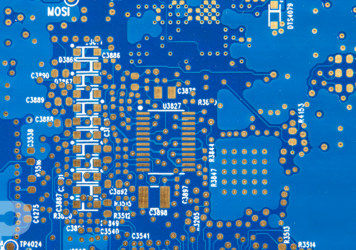

Printed Circuit Board (PCB) Via Protection: Strategies and Standards

This blog is an introduction to a larger white paper that features 7 different via protection types. Download the full white...

Flexible Printed Circuits: PICA’s Expertise in Material Selection

Flexible Printed Circuits (FPC) are revolutionizing the electronics industry with their unique combination of flexibility, reliability, and lightweight construction....

6-Layer ELIC Rigid Flex Printed Circuit Board / Rigid Flex PCB

A 6-Layer ELIC (Every Layer Inter-connect) Rigid Flex Printed Circuit Board / Rigid Flex PCB is an advanced and...

Shielding Solutions to Protect Your FFC Cables

Ever increasing signal speeds and high noise environments make EMI/RFI shielding an essential requirement for FFC’s (Flat Flexible...