Dynamic Flex Circuits for High-Cycle Bending

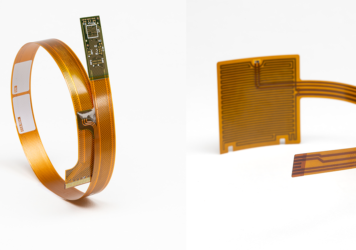

Flexible Circuits Designed for Continuous Motion

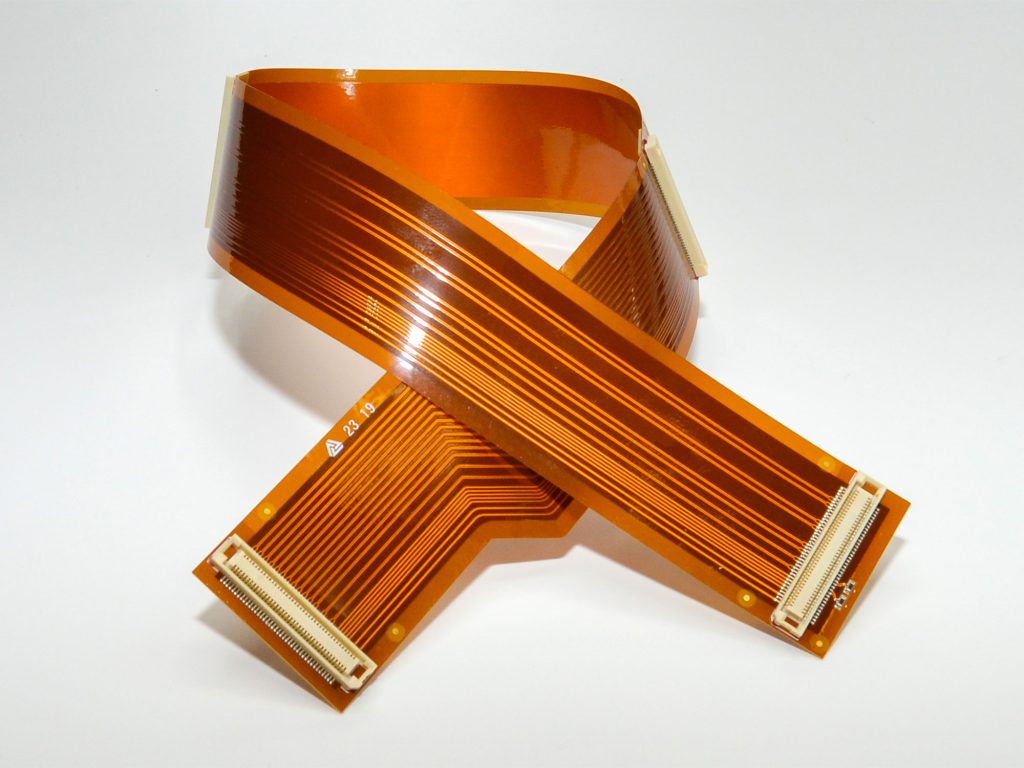

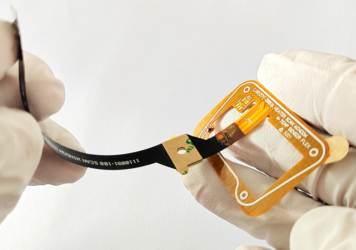

Dynamic flex printed circuits are engineered to bend repeatedly—thousands to millions of times—without cracking or drifting out of spec. PICA’s design-driven team optimizes copper grain direction, bend radii, layout, and material stacks to deliver stable, repeatable performance throughout the product lifecycle.

These circuits enable reliable motion in wearables, medical devices, robotics, automotive controls, and foldable electronics where space is tight and durability cannot fail.

Why Choose Dynamic Flex Printed Circuits?

• Proven High-Cycle Durability

Validated for continuous bending in products requiring years of repeated motion.

• Optimized Conductor Strain

Copper thickness, trace orientation, and grain structure are tuned to prevent fatigue.

• High Reliability Without Extra Connectors

Eliminates moving wire harnesses, reducing failures and simplifying assembly.

• Stable Electrical Characteristics Under Motion

Maintains consistent impedance and signal performance while flexing.

• Engineered Bend Regions

Designed to protect pads, vias, and terminations from stress-induced cracking.

Dynamic Flex Capabilities – Highlights

• Designed for 100,000 to 1,000,000+ bend cycles

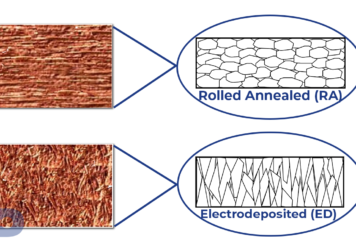

• RA (Rolled Annealed) copper and ultra-thin foils for extended flex life

• Adhesiveless polyimide for reduced thickness and improved fatigue resistance

• Air-gap and window constructions to minimize stress in bend areas

• Dynamic-focused routing: staggered traces, filleted corners, tear-stop features

• Supports controlled impedance and high-speed designs under motion

• Selective stiffeners, strain relief, and connector reinforcement

• Bend support for 90° and 180° motion systems

Global Design & Manufacturing Support

With engineering in the U.S. and production capabilities in Malaysia, PICA supports rapid prototyping through volume manufacturing of dynamic flex circuits. Our early-stage design collaboration helps prevent fatigue issues before they make it to production, saving time and cost.

Benefits of Dynamic Flex Circuits

High-Cycle Motion Reliability

Dynamic flex circuits survive repeated bending through specialized copper selection, thickness control, and strain-free routing.

Reduced Mechanical Stress

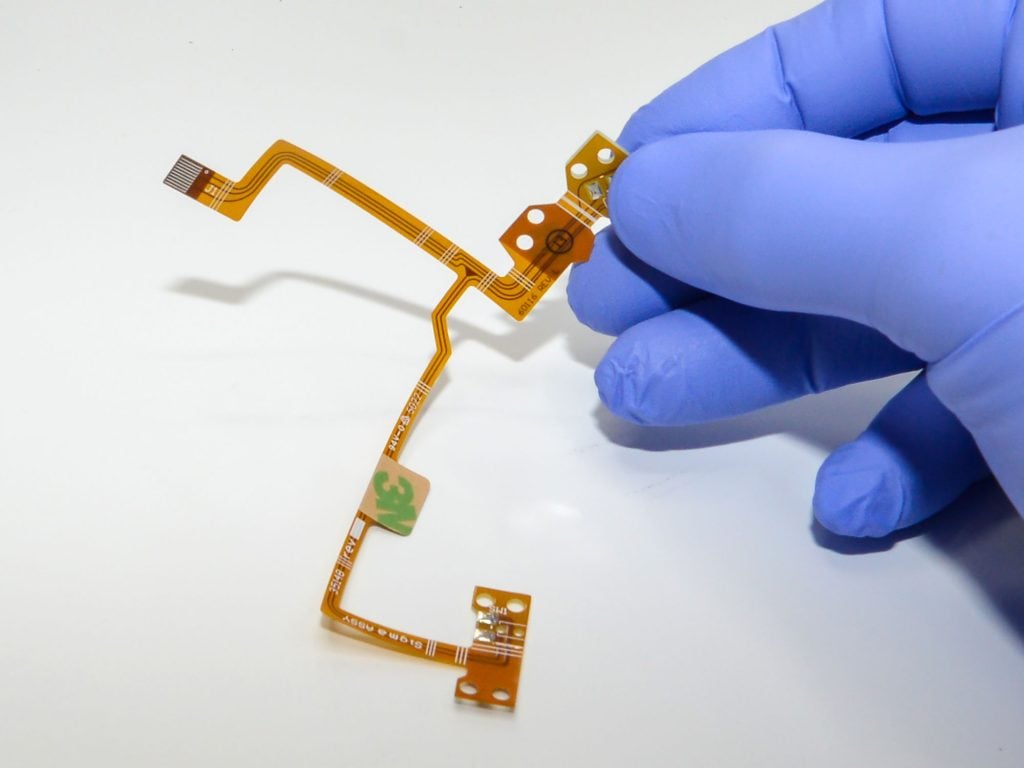

We control strain at critical areas—like pads, vias, and connectors—ensuring fatigue-free durability.

Thin, Lightweight Motion Systems

Eliminate bulky wire harnesses with ultra-light, space-saving flex elements ideal for wearables and compact medical devices.

Cleaner, More Reliable Interconnects

Dynamic flex bridges moving assemblies without connectors, improving reliability and reducing assembly complexity.

Consistent Electrical Performance in Motion

Impedance and electrical values stay stable even during repetitive bending, protecting high-speed signals and sensitive sensors.

Markets We Serve with Dynamic Flex Circuits

Wearables & Consumer Electronics

Hinges, straps, foldable displays, and compact portable electronics benefit from small-radius flexing.

Medical Devices

Miniaturized circuits for patient-monitoring, diagnostic sensors, and body-worn equipment requiring motion reliability.

Automotive & Transportation

Used in rotating displays, steering systems, seat controls, and vibration-heavy environments requiring robust motion tolerance.

Industrial Automation & Robotics

Continuous movement in sensors, actuators, and robotic joints demands highly reliable bend-tolerant circuitry.

Communications & Instrumentation

Dynamic flex enables repositionable sensor heads and sliding mechanisms with stable electrical performance.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

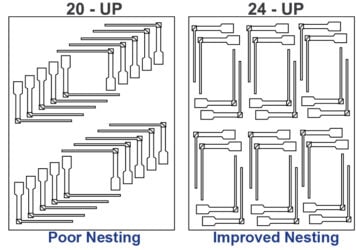

Minimizing Material Waste Through Optimized Nesting

When designing flexible circuits, especially those with irregular shapes, it’s easy to overlook how layout decisions impact manufacturing efficiency. But...

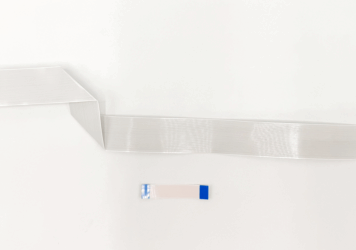

Flat Flexible Cables (FFC): A Cost-Effective and Scalable Interconnect Solution

For engineers balancing performance, flexibility, and cost, Flat Flexible Cables (FFC) remain one of the most efficient...

Conductive Inks and Their Role in Flexible and Printed Electronics

Conductive Inks and Their Role in Flexible and Printed ElectronicsAs electronics continue to evolve beyond rigid, boxy enclosures, the materials...

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

Understanding Flexible Printed Circuit (FPC) Cost Drivers

Flexible Printed Circuits (FPCs) are essential components in modern electronics, enabling lightweight, compact, and high-performance designs. However, they come...

Common Mistakes Made by PCB Designers When Designing Flexible Circuits (FPCs)

Flexible Printed Circuits (FPCs) are widely used due to their lightweight, flexible, and compact nature, making them ideal for...

Adhesiveless Technologies for Flexible Circuits: Unlocking Next-Generation Performance

In the world of flexible electronics, the shift from traditional flexible copper-clad laminates (FCCLs) to adhesiveless materials represents a significant...

The Best Copper Conductor for Flex-to-Install & Dynamic Applications

When it comes to choosing the right conductor material for flexible printed circuits (FPC), the primary consideration revolves around...