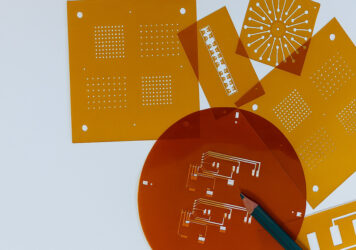

The Best Copper Conductor for Flex-to-Install & Dynamic Applications

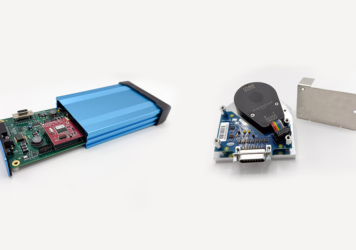

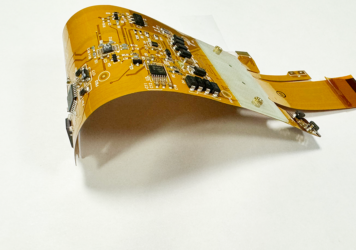

Pascal Delloue2025-08-26T13:22:40+00:00When it comes to choosing the right conductor material for flexible printed circuits (FPC), the primary consideration revolves around how the material performs under specific application conditions. This is especially critical in dynamic applications where the circuit is subject to repeated bending or flexing. Such applications necessitate conductors that are not only thin but also exhibit exceptional fatigue life, ensuring reliability and functionality over time.

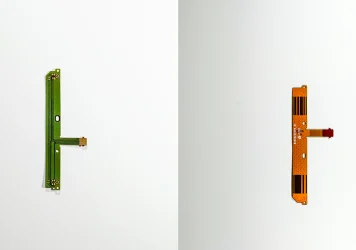

Among the various materials available, copper stands out as the most used conductor material in FPCs due to its excellent electrical conductivity and flexibility. Copper foils used in FPCs are available in various thicknesses ranging from as thin as 5 micrometers to as thick as 500 micrometers. Typical copper thicknesses used include 9µm, 12µm, 18µm, 24µm, 35µm, 70µm, and 105µm. These options allow for a versatile application across different types of flexible circuits, accommodating both light-weight, high-flex designs and more robust needs.

While copper is predominant, there are other materials like copper-nickel alloys, silver, carbon, and conductive inks that are also used based on specific requirements such as cost, conductivity, and mechanical properties. Each of these materials brings distinct characteristics that can be beneficial depending on the application.

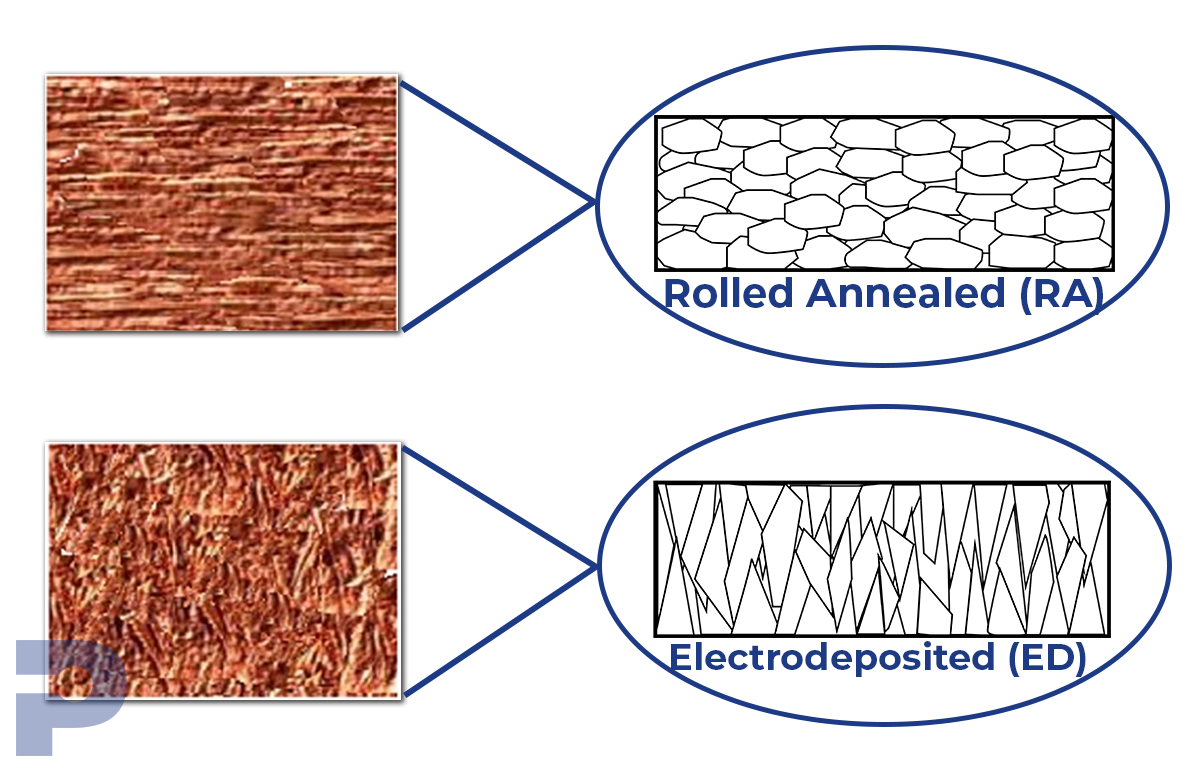

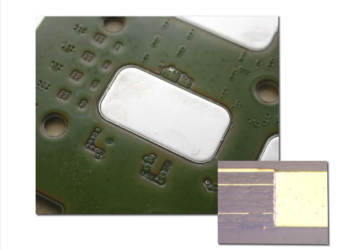

Two notable forms of copper used in FPCs are Electro Deposited (ED) Copper and Rolled Annealed (RA) copper, each having unique grain structures that influence their performance in flexible applications.

Production of RA Copper: RA copper is manufactured through a meticulous process that involves the rolling and annealing of thick copper ingots. This repeated process of rolling and annealing helps in achieving a horizontal grain structure that is parallel to the foil plane, enhancing its flexibility and resistance to cracking under repeated flexing.

Talk to an Engineer

Contact us today to schedule an appointment to talk to an engineer about your current project or general questions.

Production of ED Copper: In contrast, ED copper is produced via an electroplating process where copper ions are deposited onto a cathode drum through electrolysis. The foil forms as it is continuously wound off the drum while it rotates, allowing for the creation of a columnar grain structure that runs perpendicular to the foil plane. Although suitable for certain applications, this type of grain structure can be more susceptible to cracking when subjected to dynamic flexing.

Choosing the right type of copper—be it ED, RA, or High Ductility ED copper (HDED)—depends largely on the specific demands of the application. For example, applications that involve significant bending or flexing are better served by RA or HDED copper due to their superior flexibility and durability under stress.

In summary, while copper remains a popular choice for flexible printed circuits due to its superior electrical and mechanical properties, the specific type of copper and its form must be carefully selected to match the unique demands of each application. By understanding the nuances of copper’s different forms and the alternatives available, PICA designers can optimize the performance and reliability of flexible printed circuits.

Contact us with any questions on copper conductors.