Advance Soldering Techniques for Printed Circuit Board Assembly

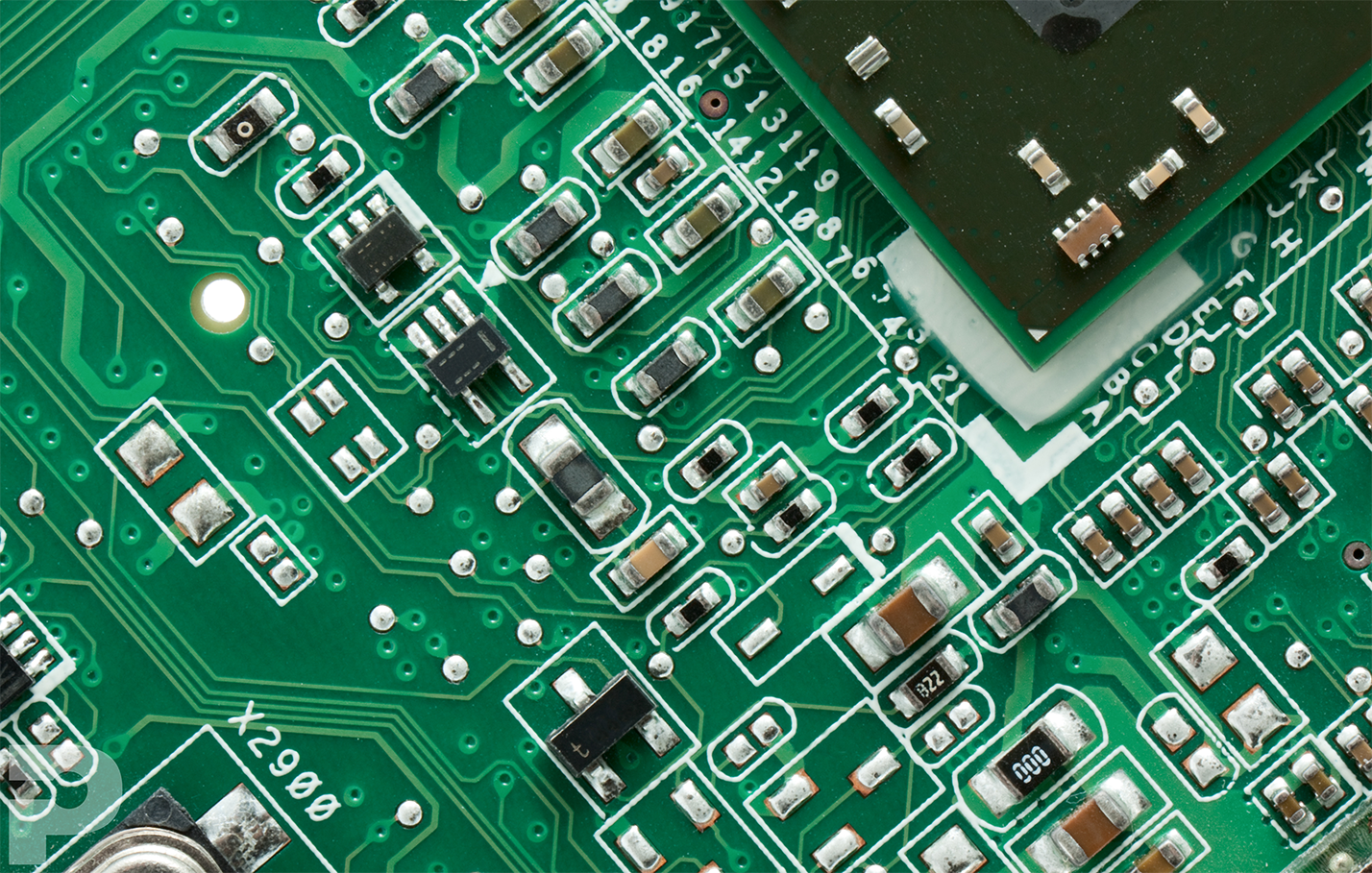

FlexPros2025-09-02T13:00:43+00:00Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy, known as solder. This process not only provides mechanical strength but also ensures reliable electrical connections.

The metal alloy used for soldering varies based on the required properties such as melting point, mechanical strength, and environmental compliance. Historically, a tin-lead (Sn-Pb) alloy was common, but health and environmental concerns have led to the adoption of lead-free alternatives like Tin-Silver-Copper (SAC), typically SAC305, and Tin-Copper (SnCu), which are favored for their reliability and compliance with regulations like RoHS. Specialty alloys, including bismuth and indium-containing solders, are also used for specific applications requiring lower melting temperatures or unique bonding characteristics. Each alloy is selected to optimize the balance between cost, performance, and environmental impact in the context of the specific electronic components being assembled.

Soldering techniques vary widely to accommodate different types of components, PCB materials, and production requirements. Each method is designed to optimize certain aspects such as precision, speed, and thermal sensitivity.

Below is a detailed overview of various soldering and interconnect techniques that are integral to modern PCB assembly:

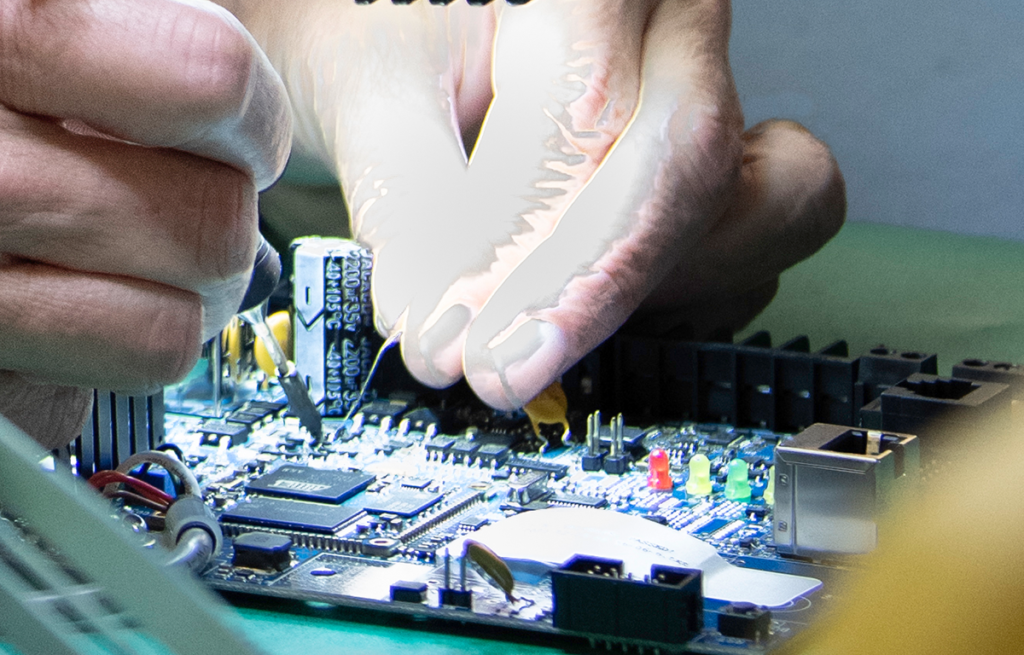

- Hand Soldering

Hand soldering is essential for prototypes and repair work. It involves manually applying heat and lead-free solder to the PCB to attach components. This method is particularly useful for small-scale production that demands precision and flexibility.

- Surface Mount Technology (SMT)

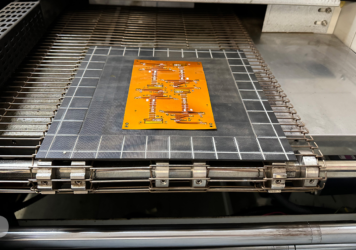

Surface Mount Technology is the standard for efficiently mass-producing electronic devices. It involves placing components directly onto the surface of PCBs, which allows for higher component density and faster assembly than through-hole methods.

- Through Hole Technology (Wave Flow Soldering)

Through-hole technology inserts component leads into pre-drilled holes on the PCB. The assembly then passes over a solder wave that solidifies to form robust electrical connections, suitable for components that must endure mechanical stress.

- Selective Soldering

Selective soldering is used for PCBs with complex layouts or where heat-sensitive components are present. It provides the efficiency of wave soldering with the precision of hand soldering, selectively targeting areas of the board to avoid heat damage elsewhere.

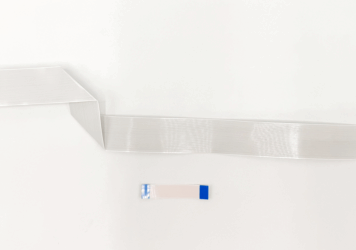

- Hot Bar Soldering

Hot bar soldering is used to attach flexible circuits to rigid boards. It employs a heated bar that applies simultaneous pressure and heat to the component leads and PCB pads, melting the solder to create a durable bond.

- Laser Soldering

Laser soldering offers high precision and control, ideal for sensitive components that could be damaged by excess heat. A focused laser beam selectively melts the solder, minimizing thermal impact on surrounding areas.

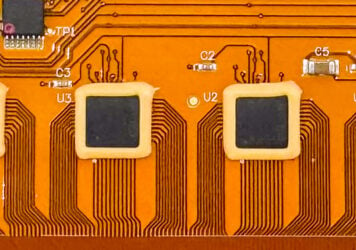

- Direct Chip Attach (DCA)

Direct Chip Attach refers more broadly to any method where a semiconductor die is attached directly onto the printed circuit board (PCB) or substrate without using an interposing package. The goal of DCA is to minimize the footprint and enhance the electrical performance by reducing the length of the connections between the die and the substrate.

- Flip Chip

Flip Chip is a specific type of DCA where the semiconductor die is “flipped” over so that the active area with the electrical connections is facing downward towards the PCB. In a typical Flip Chip process, the die is connected to the substrate via solder bumps that are deposited on the die pads. After positioning the die, heat and pressure are applied to reflow the solder, establishing the mechanical and electrical connections.

- Aluminum Wedge Bonding

Aluminum wedge bonding uses an aluminum wire to connect the semiconductor die to the PCB. A wedge tool applies ultrasonic energy to bond the wire between the die and substrate, ensuring a strong mechanical and electrical connection.

- Gold Ball Bonding

Gold ball bonding uses a fine gold wire that forms a ball at its tip, which is then bonded to the chip’s contact pad and the substrate using ultrasonic energy, creating a robust bond.

- Anisotropic Conductive Film & Adhesive (ACF & ACA)

These materials are predominantly used in the assembly of LCD screens, where they facilitate electrical connections in one direction while maintaining optical clarity.

Want to learn more about PICA’s component assembly capabilities? Click the link below.

- Conductive Epoxy

Conductive epoxy is an adhesive that conducts electricity, used to bond components to PCBs in situations where traditional soldering could damage sensitive parts. It is especially valued in high-temperature or chemically aggressive environments.

- Robotic Soldering

Robotic soldering systems use automated robots with soldering irons or dispensers to precisely and consistently solder components onto PCBs. Ideal for high-volume production, these systems enhance throughput and accuracy compared to manual soldering. They operate continuously without fatigue, ensuring uniform quality and reducing defects.

- Vacuum and Nitrogen Soldering

Vacuum soldering minimizes voids in solder joints by using a vacuum environment, which reduces outgassing and flux residues. This technique enhances the mechanical and thermal properties of solder connections. The process can incorporate nitrogen or hydrogen atmospheres to further improve joint cleanliness and quality.

Nitrogen soldering uses an inert nitrogen atmosphere to prevent oxidation, resulting in smoother and more reliable solder joints. It is particularly effective in wave soldering, reducing dross formation and improving solder wettability.

At PICA Manufacturing Solutions, we are equipped to handle a wide range of soldering and interconnect techniques, each playing a vital role in PCB assembly. Our capabilities are tailored to meet specific application needs, environmental conditions, and production scales. As technology advances, we continuously adapt and refine our methods to address the evolving and complex demands of advanced electronic manufacturing, whether at our US facility in Derry, NH, or our plant in Kuala Lumpur, Malaysia.

Contact us with any questions on soldering techniques for printed circuit boards.