4 factors that can cause voiding in Ball Grid Arrays (BGA)

Michael Bedard2025-08-26T12:41:08+00:00- Ball Grid Arrays (BGAs) are crucial components widely employed in the electronic manufacturing industry owing to their compact size. However, due to their high density, detecting defects through visual inspection alone can be challenging, while destructive testing poses the risk of compromising voiding defects.

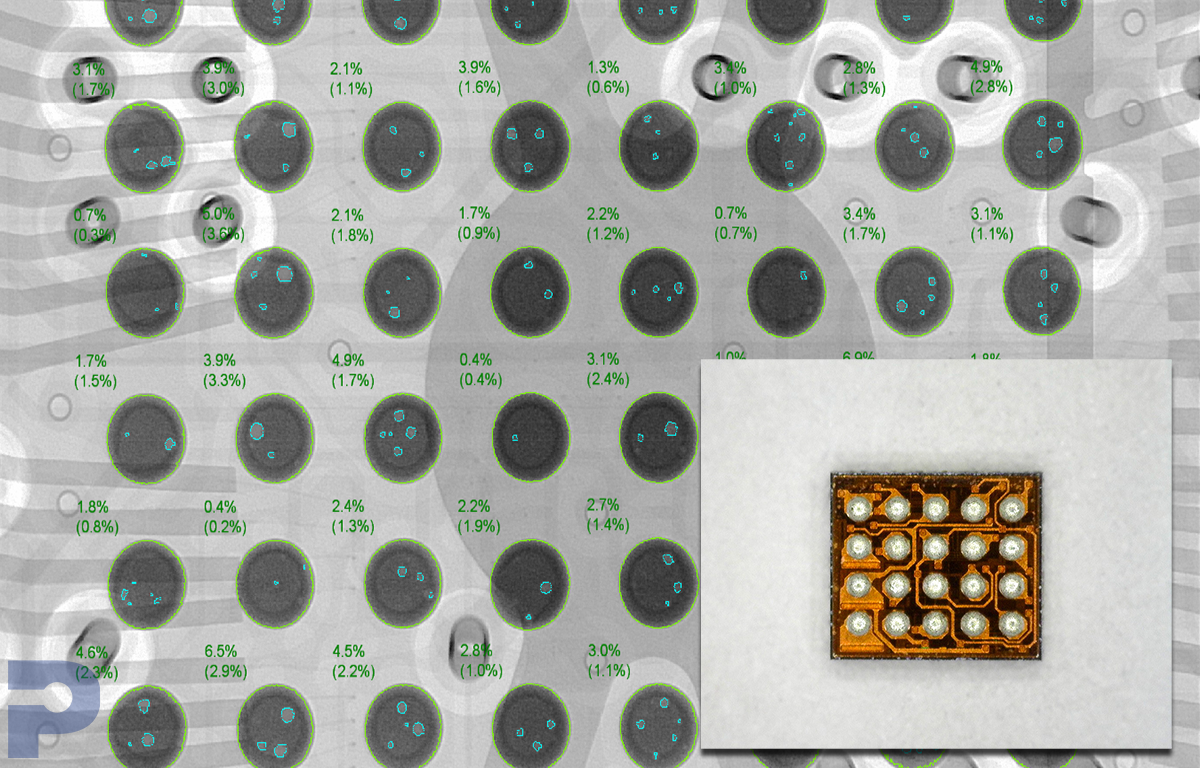

X-ray inspections offer a non-destructive testing solution for scrutinizing potential voiding issues in BGA component assembly processes. Once BGAs undergo inspection and analysis for voiding issues, it’s essential to review the manufacturing process for common errors that might contribute to voiding problems.

Voiding in Ball Grid Arrays can manifest at various stages of manufacturing. Many issues leading to voiding can be easily mitigated to minimize voiding during the assembly process.

Ensure precision with PICA’s on-site X-ray inspection, delivering real-time analysis for BGA, PCB assemblies, and solder joints without disrupting production. Detect defects, accelerate QA, and ensure compliance.

1. Solder Paste Handling: Proper handling and storage of solder paste are critical to prevent voiding. Storing solder paste correctly, often in a refrigerator when not in use, can significantly reduce voiding issues. Refer to the solder paste manufacturer’s datasheet for storage instructions and ensure that expired paste is not used. Additionally, allow solder paste to reach room temperature before application.

2. Reflow Time and Ramp Rate: The oven profile, comprising temperature settings in each zone of the reflow oven, is crucial for minimizing voiding. Follow the reflow ramp rate specified by the solder paste manufacturer to allow sufficient time for outgassing, releasing any trapped particles or gases during melting. Failure to adhere to these parameters can result in voiding in final solder joints.

3. Component Manufacturing: Voiding may also originate during component manufacturing. X-ray inspection before circuit board assembly can identify defects if they persist after addressing other factors during assembly.

4. Circuit Board and Component Contamination: Ensure proper storage of circuit boards and components in airtight, clean containers to prevent contamination by moisture, dust, oils, or other elements that could damage or oxidize solder pads. Keep circuit boards and components in their designated containers until the assembly process begins.

These are just a few common factors contributing to voiding in Ball Grid Array components during manufacturing and assembly. Addressing these parameters diligently can help mitigate voiding issues and enhance the reliability of electronic systems.

Contact us with any questions on Ball Grid Array.