Click the button below to listen to the audio version of our Vivo Recording and Optogenetics case study.

Academic Research Interconnect Case Study

UC San Diego Lim Lab Sensor Board Interconnect for Compact, High Flex Applications

A UC San Diego neurobiology research team in the Lim Lab develops tools and experiments to study basal ganglia circuitry and behavior using approaches such as in vivo recording and optogenetics in mice.

To support a custom research instrument, the team needed a reliable interconnect to link a main electronics board to a sensor board in a tight mechanical envelope.

The challenge

The research team contacted PICA looking for an interconnect solution that could handle three competing requirements:

- Slim, low profile packaging to fit within a compact assembly

- High density routing in a narrow flex width

- Continuous flexing during operation, requiring long term mechanical reliability

Off the shelf cabling and rigid interconnect options risked adding bulk, limiting routing density, or failing under repeated bending.

PICA’s engineering approach

PICA reviewed the application details and identified flexibility and mechanical endurance as primary drivers, alongside routing density and overall profile. The solution required material and process choices designed to preserve flex performance while meeting electrical and assembly needs.

The solution

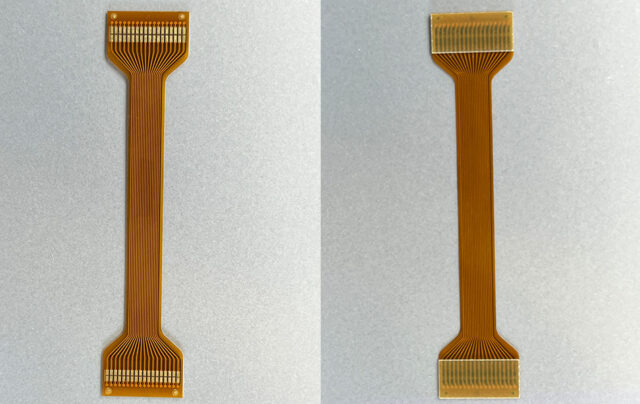

PICA delivered a double sided flexible printed circuit that accommodated the full routing set while maintaining a narrow width and low profile.

Key design and fabrication elements included:

- Double sided flexible printed circuit to support high density routing in a slim form factor

- Rolled annealed copper on an adhesiveless base laminate to improve bend performance during continuous flexing

- Button plating selected to help preserve flexibility while meeting interconnect requirements

- Turnkey build support including design, flex fabrication, and assembly of the two board connectors

What PICA delivered

- Engineering review and design support based on the application constraints

- Fabricated flexible printed circuits built for repeated bend use

- Assembled connector interfaces for main board and sensor board integration

- A turnkey interconnect solution to reduce lab integration time and simplify procurement

Outcome and impact

With a purpose built flex interconnect, the research team received a compact, high density, low profile link between boards that was designed specifically for continuous bending during operation. This supported faster integration into their research hardware and improved confidence in mechanical reliability for ongoing experimentation.

Why it matters for academic programs

Academic research hardware often combines tight mechanical packaging, custom sensing, and frequent handling or motion. The Lim Lab’s work focuses on understanding neural circuits and behavior in animal models, which commonly depends on compact instrumentation and dependable signal pathways.

PICA helps bridge the gap between lab prototypes and buildable, repeatable interconnect solutions through practical engineering support and turnkey execution.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Auxiliary Materials in Flex PCB Builds

Stiffener, EMI Shielding, Release liners, spacers, marking inks, thermally conductive adhesive films, and PSA selection guidance.When engineers...

Flex PCB Adhesives and Bonding Guide

Thermoplastic vs thermoset adhesives, adhesiveless constructions, and the process factors that drive delamination riskIn flex circuits, reliability...

Flex PCB Substrate Deep Dives Beyond Polyimide

PET vs PEN, LCP, PTFE/fluoropolymers, and specialty films like PEI/PEEK: when each wins, where each struggles, and what it means...

Highlights from MD&M WEST 2026

MD&M West 2026 in Anaheim brought together medtech, automation, design/manufacturing, plastics, and packaging, so the biggest trend wasn’t one...