Ultra-Thin Flexible Printed Circuits (FPC) for Lightweight, Compact Electronics

Flexible Circuit Boards Engineered for Minimal Thickness, Maximum Performance

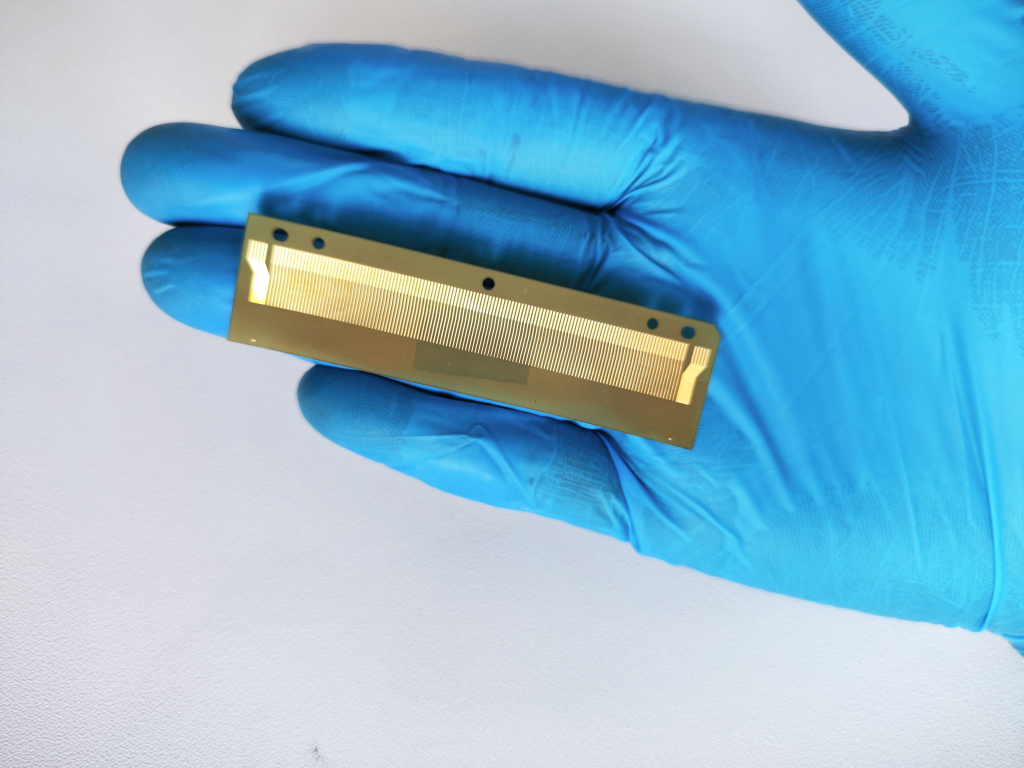

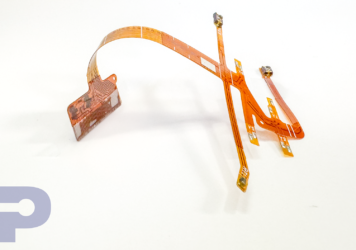

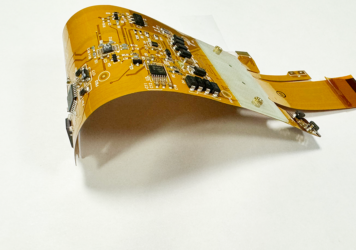

Ultra-thin flexible printed circuits let you push into ultra-compact form factors where every gram and micron count. PICA delivers precision FPCs with ultra-thin materials and advanced manufacturing for wearables, medical devices, foldables and space-constrained applications.

Why Choose Ultra-Thin Flexible Printed Circuits?

- Minimal Thickness & Weight – Ultra-thin substrates allow board thicknesses down to ~0.20 mm or less, enabling slimmer, lighter assemblies.

- Space-Constrained Packaging – Ideal for wearable tech, medical implants, foldable electronics and any application where height is restricted or comfort is key.

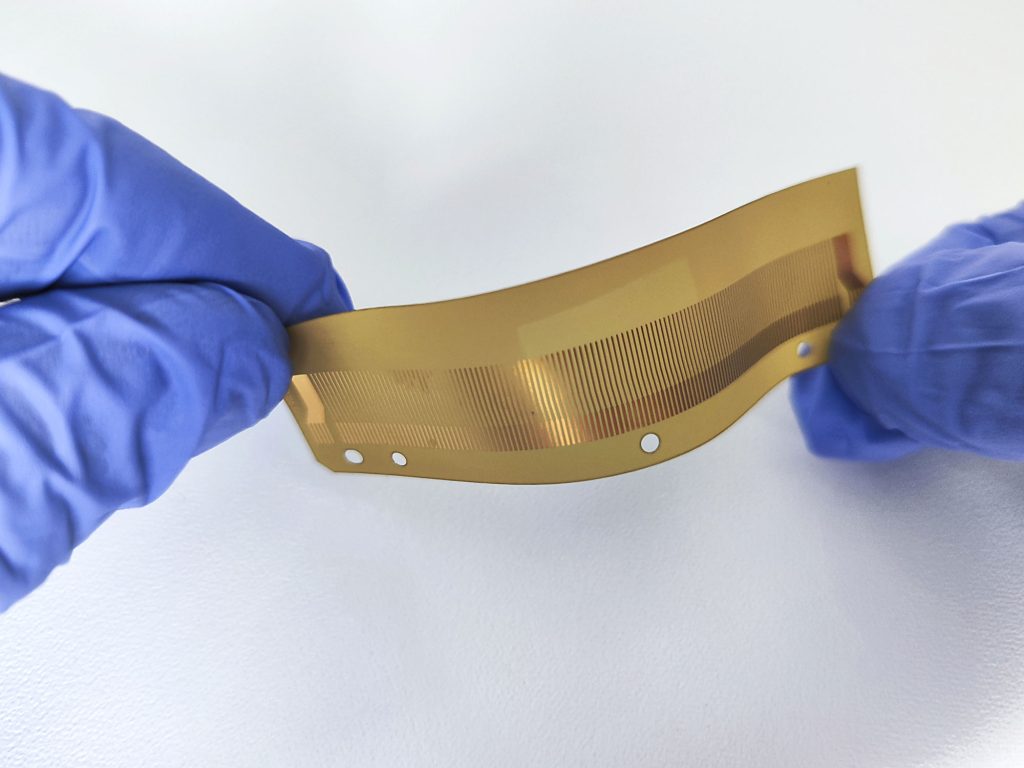

- High Flexibility & Conformability – Ultra thin construction enables tight bend radii, fold‐to‐install, even wraparound designs.

- Precision Manufacturing & Materials – Achieved through adhesive-less polyimide stacks, laser-direct imaging, and specialized handling for ultra-thin panels.

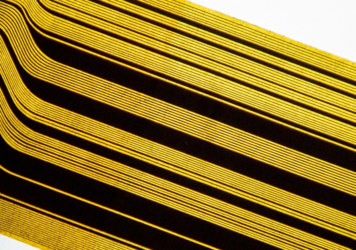

- Optimized for Miniaturization – Supports fine-line routing, small pad designs, low mass interconnects for next-gen devices.

Ultra-Thin FPC Capabilities – Highlights

- Ultra‐thin constructions: e.g., 3 µm copper on 25 µm polyimide; 18 µm copper on 12.5 µm polyimide; finished thickness as low as 0.20 mm ± 0.08 mm.

- Adhesiveless / thermoplastic polyimide (TPI) material sets for improved durability and precision.

- Laser Direct Imaging (LDI) and fine‐line etching for ultra-thin substrate processing and trace precision.

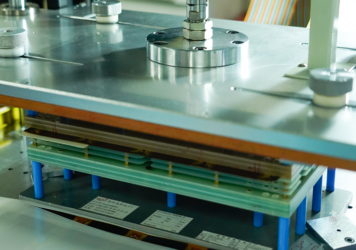

- Specialized process controls for ultra-thin panel handling: thickness/flatness, scratch resistance, warpage mitigation.

- Design guidance: low mass, low profile circuits for wearables, sensors, compact modules, with engineering collaboration for manufacturability and reliability.

Global Design & Manufacturing Support

PICA’s engineering team works closely with your design team—from concept to volume production—to define ultra-thin stack-ups, material selection, bend features, flatness tolerances and assembly readiness. Early collaboration ensures manufacturability, reliability and efficient production of ultra-thin flex circuits for your application.

Benefits of Ultra-Thin Flexible Circuits

Ultra-Low Profile & Lightweight

These circuits enable form-factors previously impossible—devices are thinner, lighter and more comfortable without sacrificing performance.

Enhanced Flexibility & Design Freedom

Ultra-thin construction supports tight bends, non-standard layouts and space-optimized routing, perfect for wearables, foldables and compact modules.

Miniaturization Without Compromise

By reducing the board thickness and weight, you free up space for more features or smaller enclosures—accelerating innovation in next-gen electronics.

Reduced Mass & Mechanical Stress

Less material means lower inertia during motion, less stress on solder joints and better overall durability in dynamic or wearable systems.

Streamlined Manufacturing & Supply Chain

With PICA’s mature processes for ultra-thin flex manufacturing, you benefit from production-ready reliability, yield assurance and scalability from prototype to volume.

Markets We Serve with Ultra-Thin Flexible Circuits

Wearables & Consumer Devices

Smart watches, fitness bands, AR/VR headsets and ultra-portable devices rely on ultra-thin flex circuits to meet form-factor and comfort demands.

Medical Devices

Implantable electronics, sensor patches, minimally-invasive devices and portable diagnostic modules require ultra-thin, reliable interconnects for patient comfort and performance.

Communications & Mobile Electronics

Foldable smartphones, ultra-thin modules, high-density antennas and wear-on-body devices require flexible, ultra-thin interconnects to meet size, weight and performance goals.

Industrial, Aerospace & Defense

In mission-critical, weight-sensitive applications (drones, satellites, space wearables), ultra-thin flex circuits allow lighter assemblies and higher integration density.

Sensor & IoT Modules

Miniature sensors, body-worn systems, barcode scanners, smart cards and interconnected modules benefit from ultra-thin circuits with minimal mass and footprint.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Ultra-Thin Flexible Circuits: Overcoming Challenges in Dielectric Substrate

In Part 1, we explored the challenges of manufacturing ultra-thin flexible circuits with a focus on the conductive layers, highlighting...

Building Ultra-Thin Flexible Circuits: Part 1 – Conductor

One of our key customers approached PICA with the challenge of manufacturing ultra-thin flexible circuits. A critical component of this...

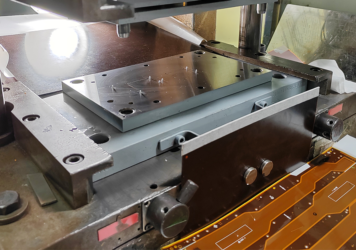

Understanding Tooling in Flex Printed Circuit Manufacturing: Fixtures, Artwork, and Testing (Part 2)

In Part 1 of this series, we discussed the essential role of mechanical tooling in Flexible Printed Circuit (FPC) manufacturing....

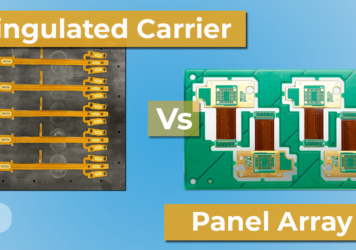

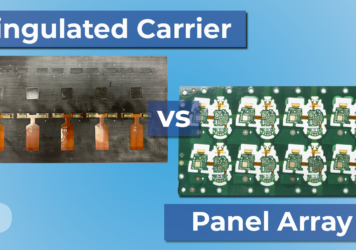

Navigating SMT Assembly Methods for Flexible Circuits Part 2

Part 2: Comparing Panel Array vs. Singulated Carrier AssemblyIn the first part of this series, we explored the key considerations...

Understanding Tooling in Flexible Printed Circuit Manufacturing: Mechanical Tooling (Part 1)

At PICA Manufacturing Solutions, producing high-quality Flexible Printed Circuits (FPCs) involves a variety of specialized tooling and processes. This blog...

Optimizing Design for Flexible Circuits Part 2: Advanced Design Strategies for Flexible Circuits

In the continuation of our series on optimizing flexible circuit designs, we delve into additional critical aspects that ensure functionality...

Optimizing Design for Flexible Circuits: Best Practices and Considerations

Flexible circuits are essential in today’s compact, lightweight devices—thanks to their ability to bend, twist, and conform to tight spaces....

Navigating SMT Assembly Methods for Flexible Circuits

This blog is the first in a two-part series that delves into the critical factors you need to consider when...