Injection Molding Services

Precision Plastic Components for Electronics & Assemblies

PICA Manufacturing Solutions offers precision injection molding services to support custom component fabrication, overmolding, and integrated electronic assemblies. With expertise across a wide range of thermoplastics, mold configurations, and part complexities, we produce everything from rugged enclosures to detailed mechanical features for advanced electronic systems.

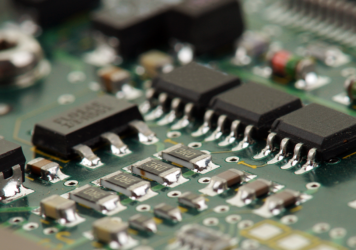

Our injection molding services extend beyond standalone parts. We specialize in electronic overmolding, seamlessly combining molded plastics with PCBs, wire harnesses, and flex circuits. This integration protects sensitive components from moisture, vibration, and mechanical strain, while improving ergonomics, durability, and overall product performance. From prototypes to full-scale production, PICA delivers reliable, scalable molding solutions that enhance both form and function.

Why Choose PICA for Injection Molding?

Custom Molding Solutions – Tailored components for enclosures, interfaces, and overmolded assemblies.

Material Expertise – Thermoplastics and elastomers selected for performance, compliance, and durability.

Integration Ready – Overmolding directly onto PCBs, flex circuits, and wire harnesses.

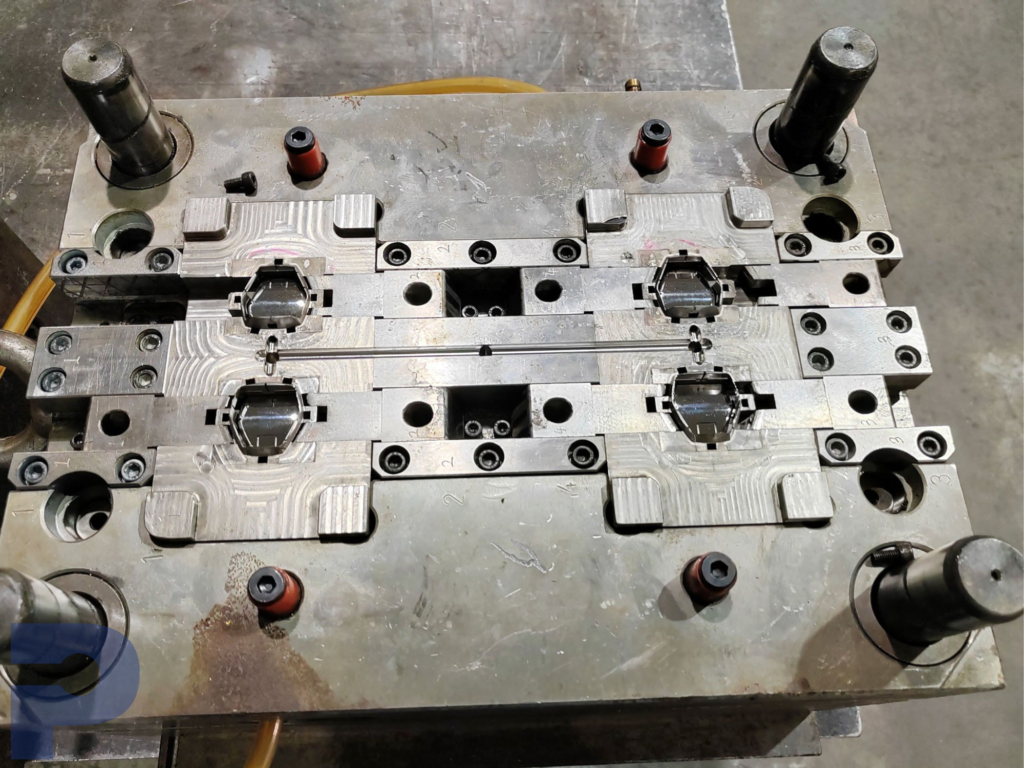

Tooling Support – In-house tooling and process control ensure dimensional accuracy and repeatability.

Scalable Production – Prototypes through high-volume runs with consistent quality assurance.

Injection Molding Capabilities (Highlights)

Wide range of thermoplastics and elastomers

Multi-cavity and custom tooling support

Direct overmolding onto electronics and wire harnesses

Complex part geometries and fine surface finishes

Prototyping, pilot runs, and high-volume manufacturing

Benefits of Injection Molding

Design Flexibility

Complex geometries, textures, and finishes can be achieved in a single molded part.

Durability & Protection

Thermoplastics and elastomers safeguard components from mechanical strain and environmental exposure.

Integration with Electronics

Overmolding directly onto PCBs, connectors, and wire harnesses creates compact, ruggedized assemblies.

Scalability

From prototype runs to high-volume production, injection molding offers consistent quality and repeatability.

Cost Efficiency

Streamlined fabrication lowers assembly steps and reduces the need for secondary enclosures.

Markets & Applications

Medical Devices

Biocompatible housings, ergonomic grips, and overmolded sensors designed for performance and safety.

Automotive & Transportation

Durable molded enclosures, harness strain relief, and modules built to withstand vibration and temperature extremes.

Industrial Equipment

Rugged parts and protective housings for robotics, automation, and heavy-duty machinery.

Consumer Electronics

Custom casings, connectors, and ergonomic enhancements for wearables, smart devices, and computing hardware.

Defense & Aerospace

Lightweight, reliable molded components engineered for mission-critical electronics.

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

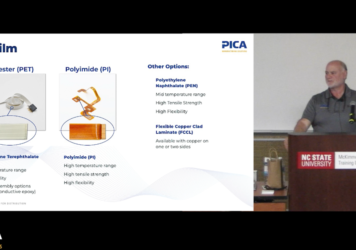

Driving Innovation in PCB Manufacturing: Insights from PCB Carolina 2024

PCB Carolina 2024 brought together industry leaders to explore advancements in PCB design and manufacturing. Joe DiPalermo, our Director of...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

Compliance: Ensuring Safety and Performance in Flexible Printed Circuit Manufacturing

When developing and manufacturing flexible printed circuits (FPCs), adhering to industry standards ensures reliability, safety, and performance. Two pivotal standards...

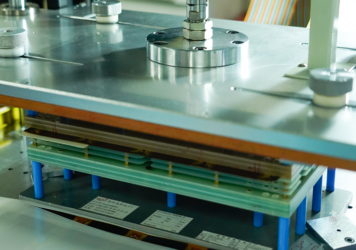

Understanding Tooling in Flex Printed Circuit Manufacturing: Fixtures, Artwork, and Testing (Part 2)

In Part 1 of this series, we discussed the essential role of mechanical tooling in Flexible Printed Circuit (FPC) manufacturing....

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Why X-Ray inspection is essential in flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA) processes

In the realm of flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA), X-ray inspection...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.