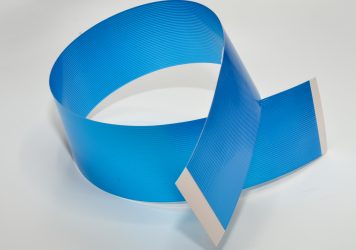

Flat Flex Cables (FFC)

Custom Flat Flex Cable Solutions for High-Performance Electronics

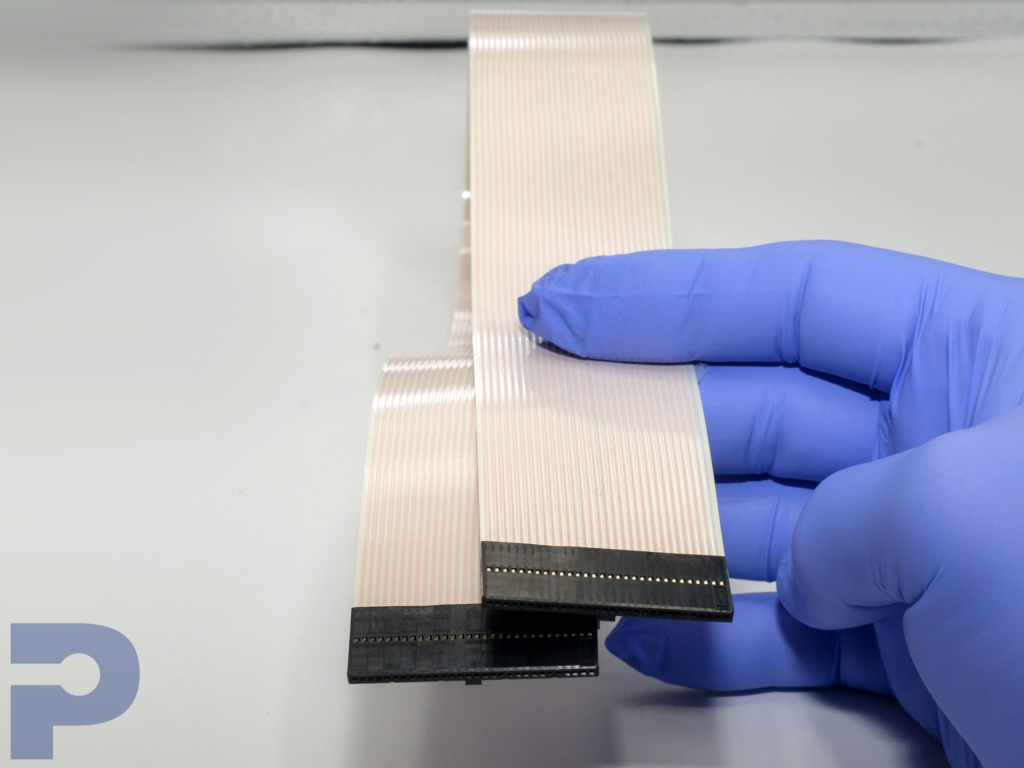

PICA designs and manufactures Flat Flex Cables (FFCs) for compact, high-speed, and space-sensitive applications. Built with precision flat copper conductors laminated between flexible insulating films, our FFCs provide a lightweight, reliable, and cost-effective interconnect solution for modern electronics.

From consumer devices and medical equipment to automotive systems and industrial controls, FFC assemblies enable tight-space routing, signal integrity, and fast production turnaround. With scalable manufacturing and engineering support, PICA delivers custom FFC cable assemblies that meet both performance and design requirements.

Benefits of Flat Flex Cables (FFC)

Space Efficiency – Ultra-slim, low-profile construction fits tight or irregular spaces where round cables cannot.

Flexibility – Easily bends, folds, and twists without damage, simplifying routing in compact electronics.

High-Speed Performance – Flat conductor geometry supports fast, reliable signal transmission.

Signal Integrity – EMI/RFI shielding options maintain performance in sensitive systems.

Cost-Effectiveness – Lightweight and streamlined, reducing bulk and lowering system costs.

Flat Flex Cable Capabilities – Highlights

PICA provides end-to-end FFC design, prototyping, and manufacturing with advanced options:

Pitch spacing from 0.2 mm to 2.54 mm

Conductor counts up to 100+ positions

Shielded and unshielded configurations

Custom lengths, terminations, and stiffeners

High-speed and high-current FFC designs

EMI suppression for sensitive electronics

For technical information on PICA’s Flat Flex Cables (FFC) capabilities, click the button below.

Why Choose Flat Flex Cables (FFC)?

Space Saving – Ultra-low profile design fits where space is tight, enabling more compact and efficient devices.

Flexibility – Bends, folds, and twists without damage, conforming to irregular layouts and tight enclosures.

High Data Speeds – Supports rapid, reliable transmissions for high-performance electronics.

Signal Integrity – EMI/RFI shielding options protect against interference, ensuring cleaner, more reliable signals.

Cost-Effective – Streamlined and affordable interconnects, especially for high-density designs.

Markets We Serve with Flat Flex Cables

Consumer Electronics – Laptops, smartphones, tablets, cameras, and printers use FFCs for slim, reliable internal connections.

Industrial Machinery – Flexible cabling for automation, sensors, and displays—easy to install and maintain in complex systems.

Automotive – Internal wiring for displays, sensors, and modules that withstand vibration and temperature extremes.

Medical Devices – Compact, reliable interconnects in diagnostics, monitoring, and surgical equipment.

Defense & Aerospace – Lightweight, rugged FFCs for avionics, flight controls, and in-flight electronics.

Flat Flexible Cables (FFC): A Cost-Effective and Scalable Interconnect Solution

For engineers balancing performance, flexibility, and cost, Flat Flexible Cables (FFC) remain one of the most efficient...

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding Flexible Printed Circuit (FPC) Cost Drivers

Flexible Printed Circuits (FPCs) are essential components in modern electronics, enabling lightweight, compact, and high-performance designs. However, they come...

Ultra-Thin Flexible Circuits: Overcoming Challenges in Dielectric Substrate

In Part 1, we explored the challenges of manufacturing ultra-thin flexible circuits with a focus on the conductive layers, highlighting...

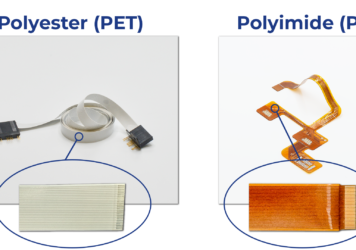

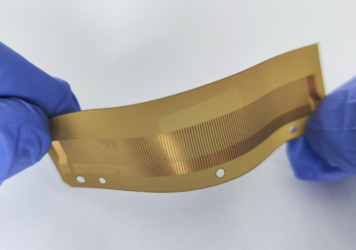

Flexible Printed Circuit (FPC) Dielectric Materials: Choosing the Best for Your Application

At PICA Manufacturing Solutions (PMS), we specialize in creating Flexible Printed Circuits (FPCs) that enable innovative designs by conforming...

Enhancing Polyimide Surface Properties for Superior Bonding in Flexible Printed Circuits

The general scope of this article is to discuss methods for treating and characterizing the surface of Kapton, a...

Flexible Printed Circuits: PICA’s Expertise in Material Selection

Flexible Printed Circuits (FPC) are revolutionizing the electronics industry with their unique combination of flexibility, reliability, and lightweight construction....

Shielding Solutions to Protect Your FFC Cables

Ever increasing signal speeds and high noise environments make EMI/RFI shielding an essential requirement for FFC’s (Flat Flexible...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.