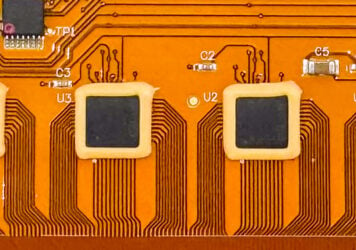

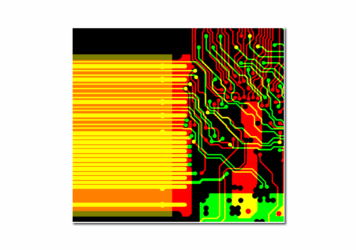

Ceramic Printed Circuit Boards (PCB)

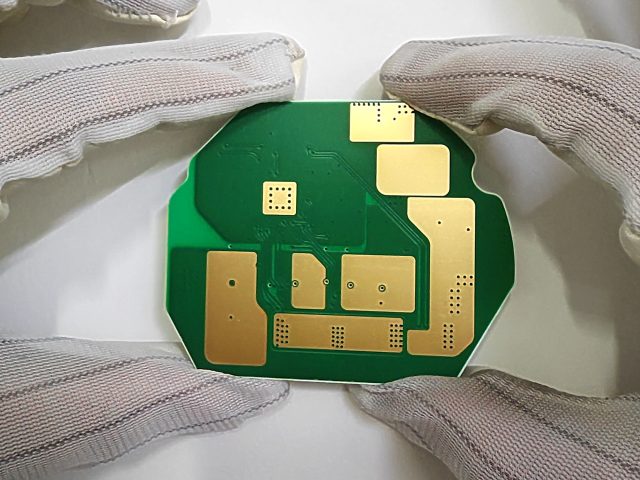

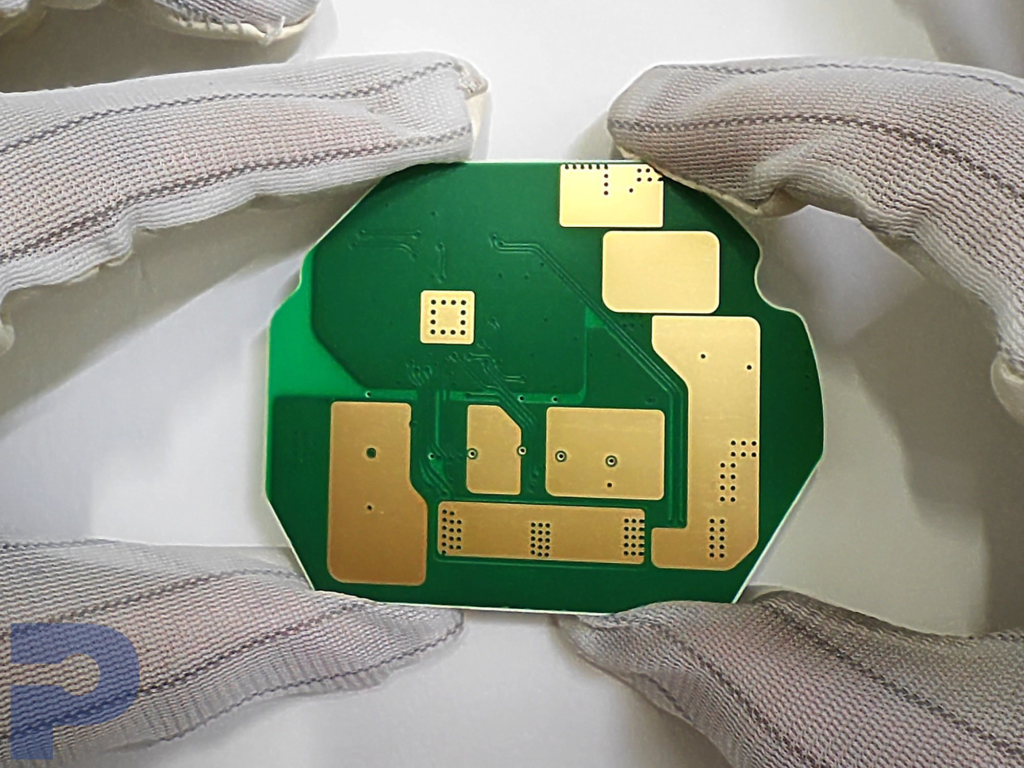

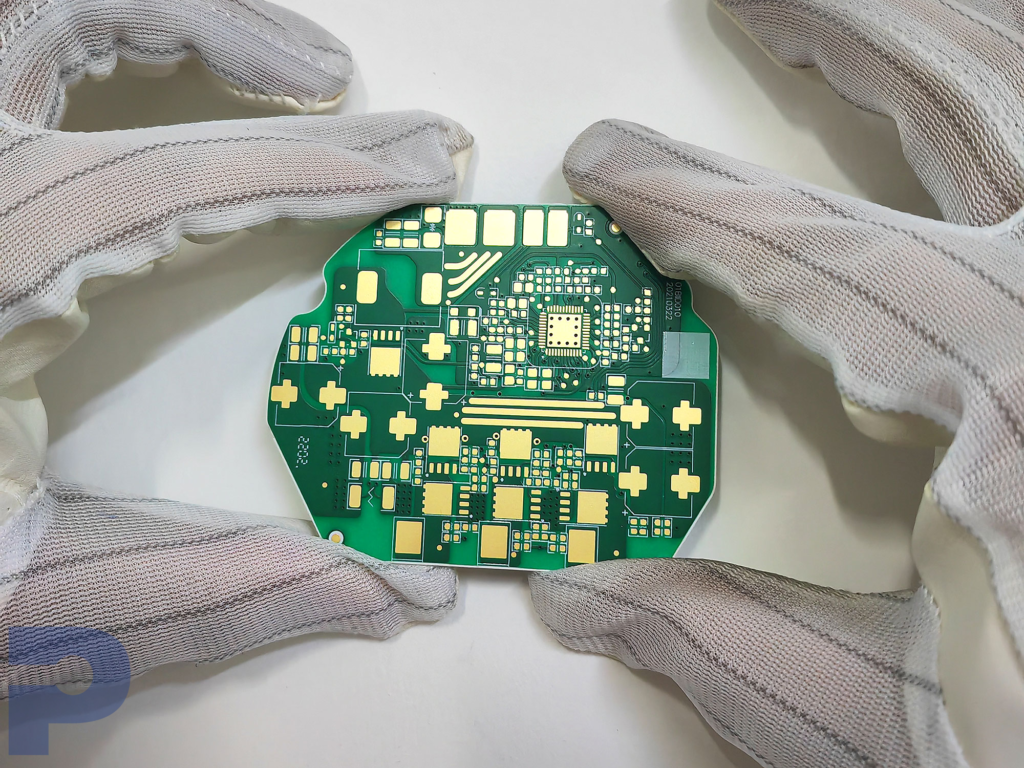

High-Performance Ceramic PCB Assemblies for Extreme Environments

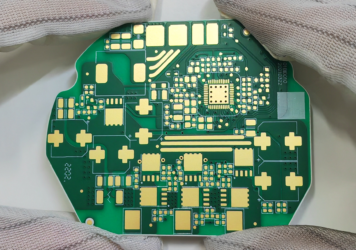

Our ceramic PCB solutions at PICA Manufacturing Solutions are built to deliver exceptional thermal, mechanical, and electrical performance where standard FR‑4 or metal‑core boards fall short. Engineered from advanced ceramic substrates such as aluminum oxide (Al₂O₃), aluminum nitride (AlN) and silicon nitride (Si₃N₄), these boards are designed for power, RF, high‑reliability, and even quantum computing cryogenic applications.

Whether you need prototypes, hybrid assemblies, or full-scale ceramic builds, PICA provides end-to-end support to meet the electrical, thermal, and mechanical demands of your system.

Why Choose Ceramic PCBs?

Thermal Conductivity – Ceramic substrates conduct heat far more effectively than FR‑4, enabling high‑power modules, LEDs, and dense electronics to run cooler and longer.

Reliability in Harsh Environments – Ultra‑low coefficient of thermal expansion (CTE), resistance to shock/vibration, and extreme temperature capability (including cryogenic) ensure durable performance under rugged conditions.

High‑Frequency & High‑Voltage Ready – With low dielectric loss and high breakdown voltage, ceramics are ideal for RF, microwave, and high‑voltage circuits.

Compact Design Potential – Supports dense interconnects, hybrid stack‑ups, and embedded passives to enable smaller, more efficient system form‑factors.

Cryogenic & Quantum‑Ready – Tested for thermal shock from –55 °C to +150 °C and with CTE values as low as ~2.6 ppm/°C (Si₃N₄), ceramic substrates maintain dimensional stability in ultra‑cold environments.

For more technical information on PICA's Ceramic Printed Circuit Board capabilities, click the button below.

Ceramic PCB Capabilities – Highlights

Technology

- Ceramics: Al₂O₃, AlN, Si₃N₄, ZTA (Zirconia Toughened Alumina)

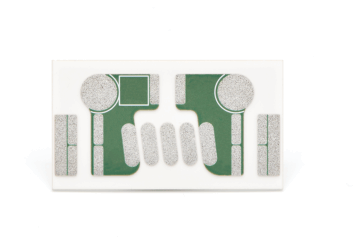

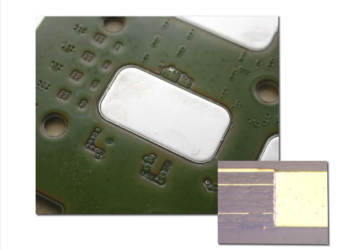

- Substrate options: Direct Copper Bonded (DCB), Active Metal Brazed (AMB)

- Multilayer ceramic builds (HTCC, LTCC)

- Laser drilling, etching, plating, and solder‐mask processing

- Thermal shock rated: –55 °C to +150 °C (suitable for cryogenic &

extreme thermal cycling) - Ultra‑low CTE materials: down to ~2.6 ppm/°C

- High bending strength: up to ~700 MPa

Materials

- Aluminum Nitride (AlN) – high thermal conductivity (170‑230 W/m·K)

- Silicon Nitride (Si₃N₄) – low CTE, excellent mechanical stability

- Alumina (Al₂O₃) – cost‑effective ceramic substrate

- Zirconia Toughened Alumina (ZTA) – enhanced toughness variant

- Copper layers: 0.127‑0.4 mm (DCB) / up to 1.2 mm (AMB)

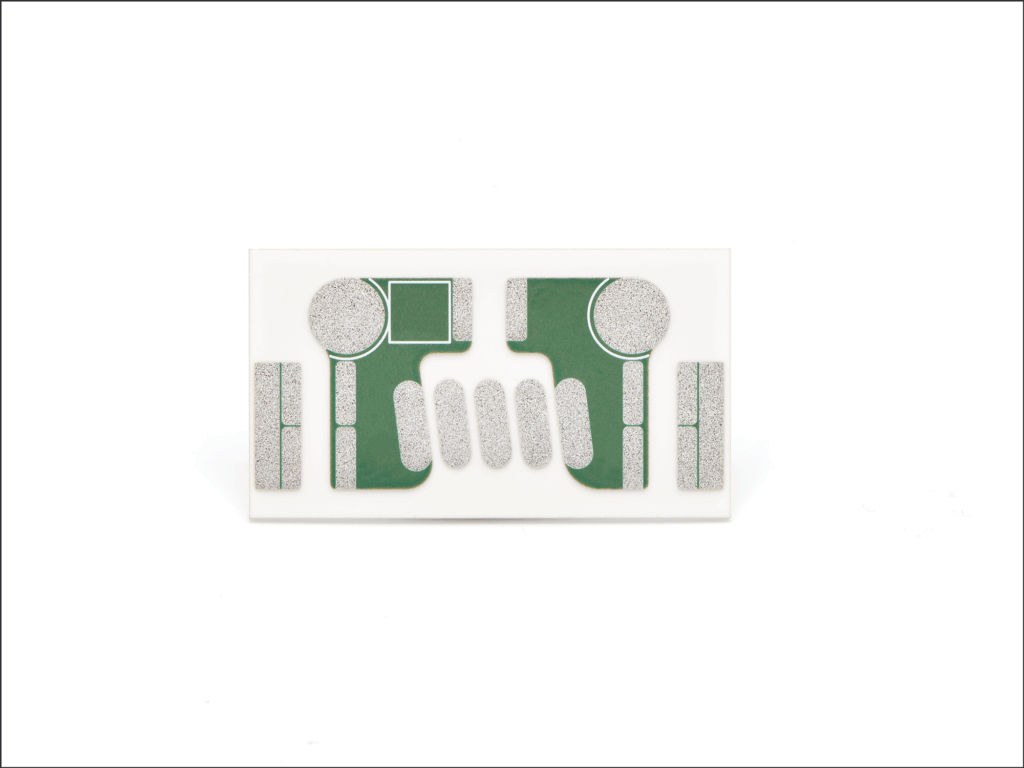

- Surface treatments: Ni, Ni+Au, Ag plating

Patterns & Holes

- Minimum line/space: ~0.2‑0.5 mm (design dependent)

- Copper mismatch ≤0.1 mm

- Etching factor ≥2.0

- Distance to board edge ≥0.15‑0.5 mm depending on thickness

- Out‑dimension tolerance: +0.2/‑0.05 mm

- Edge chipping control: ≤½ board thickness

Surface Finishes

- Bare copper / antioxidant

- Ni (2‑8 µm) selective

- Ag (0.1‑1.0 µm) selective

- Ni + Au (Au 0.01‑0.10 µm) selective

- Custom plating options available on request

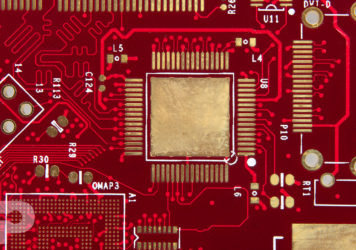

Benefits of Ceramic PCBs

Superior Thermal Management

Ceramic substrates conduct heat far more effectively than FR-4, enabling high-power applications like LEDs, power electronics, and RF systems.

Enhanced Reliability

Low CTE, corrosion resistance, and excellent thermal stability ensure long-lasting performance in harsh environments.

High-Frequency & High-Voltage Ready

Low dielectric loss and high breakdown voltage make ceramics ideal for RF, microwave, and power-conversion designs.

Compact & Versatile

Supports high-density interconnects and hybrid configurations, reducing system size while improving efficiency.

Harsh-Environment Durability

Withstands vibration, shock, and extreme temperatures, making ceramic PCBs a reliable choice for aerospace, defense, and industrial equipment.

Markets We Serve with Ceramic PCBs

Medical

Biocompatible and thermally stable substrates for implants, sensors, and diagnostic tools.

Automotive

Handles heat, vibration, and chemical exposure in advanced driver systems, EVs, and heavy equipment.

Telecom & RF

Low dielectric loss materials support high-frequency communication, radar, and microwave applications.

Defense & Security

Lightweight, rugged boards designed to withstand vibration, radiation, and thermal extremes.

Power Electronics & LEDs

High thermal conductivity ensures efficient heat dissipation for high-power and lighting systems.

Environmental Resilience in Flex PCB Design

Part 1: High-Temperature Flex Circuit Design – Engineering for Heat Resistance

In aerospace, automotive, industrial,...

Compact Power, Cooler Systems: The Case for Ceramic PCBs in Modern Electronics

Modern electronics are expected to run hotter, switch faster, and survive harsher environments than ever. Standard FR-4 hits its limits...

Streamlining PCB Production with DFM at PICA Manufacturing Solutions

Design for Manufacturability (DFM) is a proactive process integral to the PICA Way, ensuring a product design aligns with each...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advanced Surface Finishes for Enhanced PCB Performance

This blog is an introduction to a white paper that contains additional information on surface finishes including: Immersion Silver or...

The Rise of Ceramic Substrate Printed Circuit Board

Ceramic substrate PCBs (Printed Circuit Boards) represent a significant advancement in circuit board technology, especially when compared to traditional...

What is Differential Impedance?

In the fast-paced realm of the PCB (Printed Circuit Board) industry, achieving optimal signal integrity is crucial for the...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.