LPI Solder Mask vs. Polyimide Coverlay: Choosing the Right Protection for Flexible Circuits

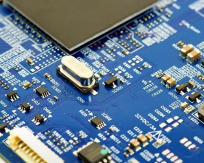

Sara Hu2025-12-17T14:59:38+00:00Protecting the copper circuitry on a flexible printed circuit (FPC) is essential to ensuring long-term reliability and performance. Two common protective approaches are Liquid Photoimageable (LPI) solder mask and Polyimide (PI) coverlay. While both serve to insulate and safeguard traces, they differ significantly in their material properties, flexibility, processing methods, and application suitability.

Below, we compare their strengths, limitations, and ideal use cases to help guide material selection for flexible designs.

Primary Advantages

• LPI Solder Mask

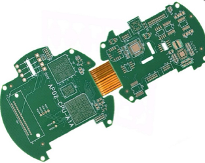

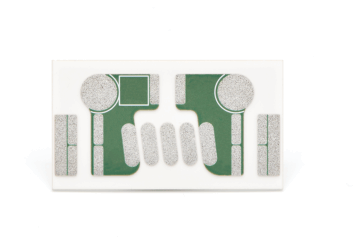

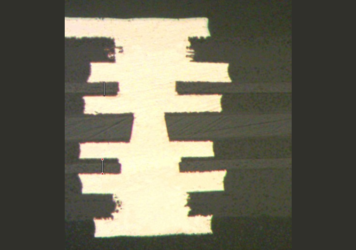

LPI solder mask offers excellent precision for fine-pitch patterns and tight registration, making it ideal for designs with dense interconnects or fine-line geometries. It can be photoimaged directly onto the circuit, reducing the need for mechanical tooling. LPI is also compatible with automated processing and is well-suited for hybrid boards or flex-rigid assemblies where rigid PCB techniques are applied.

• Polyimide (PI) Coverlay

PI coverlay provides superior mechanical protection and flexibility, maintaining insulation and adhesion even under repeated bending and thermal cycling. It’s a proven solution for traditional flex applications where long-term durability, chemical resistance, and mechanical robustness are critical

.

Flexibility and Mechanical Durability

• LPI: Offers moderate flexibility, but its brittleness under repeated bending limits use in true dynamic flex regions. It’s best suited for static or limited-flex designs, or for flexible areas that experience minimal motion.

• PI: Provides excellent mechanical resilience, maintaining adhesion and insulation through repeated bending, folding, or vibration. It’s the preferred choice for dynamic flex and moving cable-type circuits.

Ready to optimize your flex design?

Talk with our engineers to choose the right protection method for your application—whether you need fine-pitch precision with LPI or long-term durability with PI coverlay. Request a design review today.

Process and Application

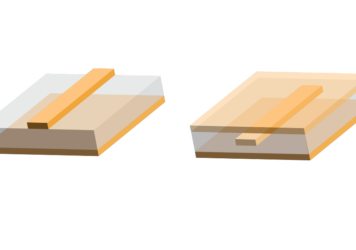

• LPI: Applied as a liquid coating and cured after exposure through a photolithographic process. This allows fine-feature definition and consistent coverage, but requires careful process control to prevent cracking or delamination in flex zones.

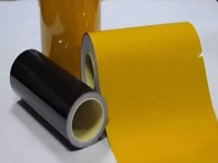

• PI: Uses a laminated film (typically PI with adhesive) that is die-cut and thermally bonded to the circuit. Though less precise for very fine traces, it offers greater toughness and uniform insulation thickness, making it more reliable for mechanical stress environments.

Thermal and Environmental Performance

• LPI: Performs well under typical PCB processing temperatures and provides good resistance to soldering and reflow. However, it may degrade faster in high-flex or high-temperature cycles compared to PI.

• PI: Withstands continuous high temperatures and harsh environments, maintaining stability in aerospace, automotive, and medical applications. Its chemical and heat resistance far exceeds that of standard solder masks.

Cost Considerations

• LPI: More cost-effective and efficient for high-volume or hybrid PCB builds that don’t demand extreme flexibility. Its photodefinable nature reduces tooling costs and supports faster prototyping.

• PI: Higher material and processing cost, but justified in applications requiring long-term mechanical and thermal reliability.

Typical Applications

LPI Solder Mask

• Flex-rigid assemblies

• Static flex circuits

• Fine-pitch interconnects

• Consumer and computing devices

Polyimide (PI) Coverlay

• Dynamic flex and wearable electronics

• Automotive sensors and medical devices

• Aerospace and defense systems

• Industrial control and instrumentation

Summary: LPI or PI?

Choosing between LPI solder mask and polyimide coverlay depends on your circuit’s mechanical, thermal, and design requirements:

• Choose LPI solder mask when you need high pattern accuracy, faster processing, and lower cost for static or semi-flexible circuits.

• Choose PI coverlay when your design requires repeated bending, high thermal endurance, or long-term environmental reliability.

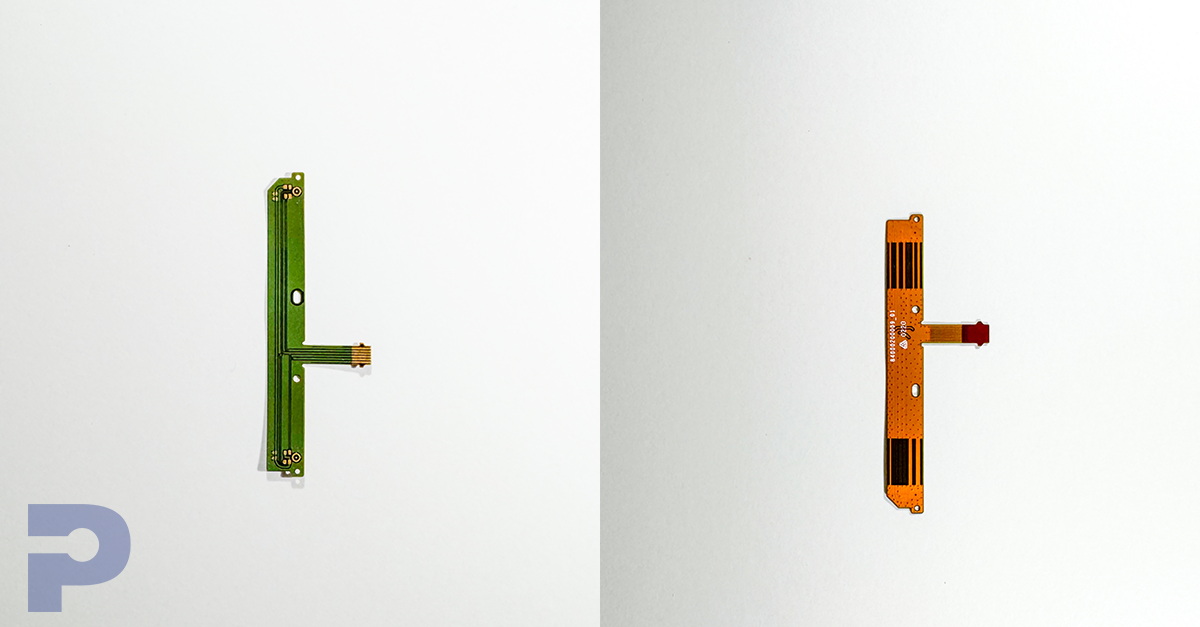

• Choose LPI solder mask at high pattern accuracy region and PI coverlay at flexible region, it is widely used method.

Both approaches play a vital role in flexible circuit manufacturing. Understanding their trade-offs helps ensure that your protection method matches your performance goals—balancing cost, flexibility, and durability.