IC Substrate & Carrier Solutions

High-Density Chip-Carrier Architectures for Advanced Packaging

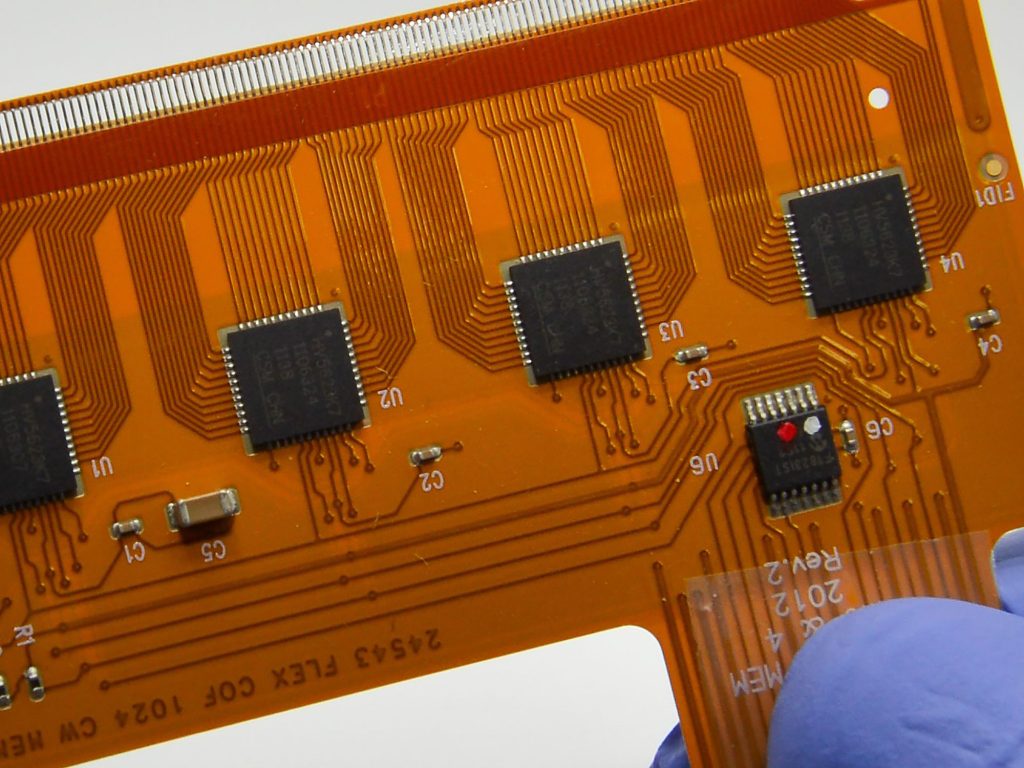

IC substrate carriers bridge the gap between bare die and printed-circuit board, delivering ultra-fine routing, high-reliability materials and precision micro-via architectures. At PICA, we provide IC-substrate carriers designed for compact packaging, thermal stress mitigation and high-frequency interconnects.

Why Choose IC Substrate & Carrier Solutions?

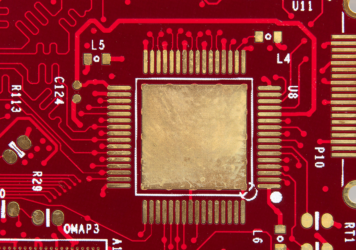

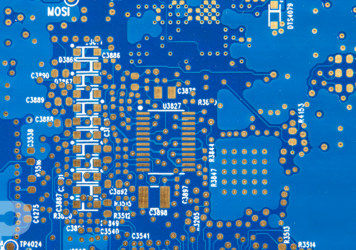

• Ultra-Fine Conductors – Typical line/space down to 30/30 µm; R&D builds to 20/20 µm.

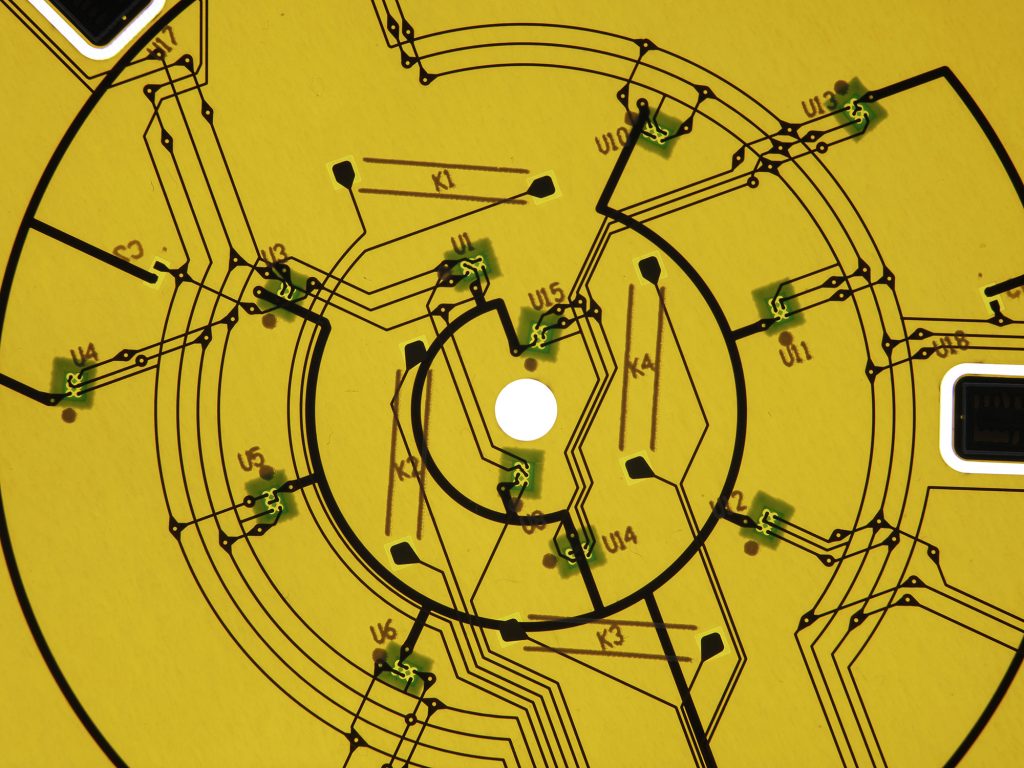

• Micro-via Precision – Via diameters as small as 50 µm using laser-defined processes.

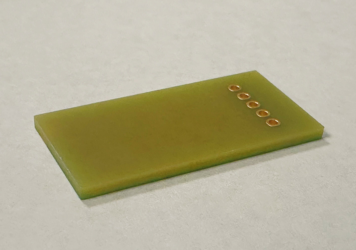

• Thermal & Dimensional Stability – Materials with Tg in the 250-300 °C range and X/Y CTE as low as 2-5 ppm/°C.

• Advanced Packaging Applications – Ideal for flip-chip modules, SiP, CSP, SLP, and other high-density integration.

• Early DFM & Material Support – PICA partners with design engineers to define stack-ups, material sets and micro-via architectures from concept to production.

IC Substrate & Carrier Capabilities – Highlights

• Supports line/space geometry of 30/30 µm, and R&D down to 20/20 µm.

• Laser-defined via diameters down to 50 µm.

• High-performance materials: BT resin systems, ceramic substrates, high Tg laminates.

• Low CTE (< 5 ppm/°C) substrates and tight dimensional control for high-reliability packaging.

• Specialist support for flip-chip, SiP, and other advanced packaging formats including substrate-like PCBs (SLP).

• Engineering collaboration from stack-up definition through manufacturing and testing for high-density chip platforms.

Global Design & Manufacturing Support

PICA offers full-lifecycle support—from engineering in the U.S. through advanced manufacturing, with deep expertise in micro-via architecture, substrate material selection and high-density layout. Engaging early in the project allows us to align material sets, define high-performance stack-ups, and ensure manufacturable, high-yield substrate carriers for sophisticated packaging applications.

Benefits of IC Substrate & Carrier Solutions

Miniaturization & Density

Carrier substrates let you route massive I/O counts in a small footprint, enabling compact packages, stacked dies and multi-chip modules.

High-Frequency & Signal Integrity

Ultra-fine conductor routing and high-performance materials support demanding signal/power delivery requirements in RF, compute-intensive and high-speed applications.

Thermal & Dimensional Reliability

With high Tg laminates and low CTE substrates, these carriers maintain structural and electrical integrity under thermal cycling and high-stress packaging conditions.

Integration Flexibility

From traditional PCB form-factors to substrate-like PCBs (SLP), flip-chip and SiP modules, carrier solutions let you bridge chip to board with optimized interconnect architecture.

High-Yield Manufacturability

By defining design rules and materials early, PICA helps reduce risk, improve yield, and support production-ready volumes for advanced packaging.

Markets We Serve with IC Substrate & Carrier Solutions

High-Performance Computing & Server Platforms

Large I/O packages, multi-chip modules and dense chip carriers benefit from the miniaturization and routing density of substrate carriers.

Mobile & Consumer Electronics

Premium smartphones, foldables, wearables and IoT devices require ultra-compact, high-density carriers to support advanced features and form-factors.

Automotive & ADAS Systems

Advanced driver assistance systems (ADAS), sensor hubs and compute modules depend on reliable packaging with thermal robustness and high signal integrity.

Networking & Telecommunications

5G/6G modules, optical transceivers and high-speed network cards require dense interconnect substrates with controlled impedance and thermal performance.

Aerospace, Defense & Mission-Critical Systems

When reliability, miniaturization and performance are non-negotiable, substrate carriers deliver the interconnect backbone for rugged, high-density modules.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

PCB Base Materials: FR-4, FR-2, CEM-1, and CEM-3

Selecting the right base material for a PCB is never a simple choice. The properties of the substrate affect everything—from...

Understanding PCB Via Holes: Through-Holes, Blind Vias, Buried Vias, & More

Printed Circuit Boards (PCBs) form the backbone of modern electronic devices, providing the physical platform for mounting and interconnecting electronic...

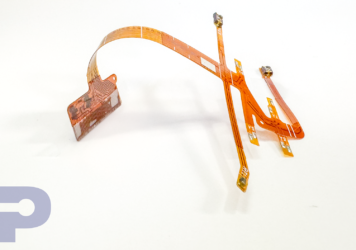

Optimizing Design for Flexible Circuits Part 2: Advanced Design Strategies for Flexible Circuits

In the continuation of our series on optimizing flexible circuit designs, we delve into additional critical aspects that ensure functionality...

Optimizing Design for Flexible Circuits: Best Practices and Considerations

Flexible circuits are essential in today’s compact, lightweight devices—thanks to their ability to bend, twist, and conform to tight spaces....

Choosing the Right Stiffener: A Guide to Materials for Flexible Circuit Support

Stiffeners are essential for providing mechanical support to flexible circuits, particularly in areas where electronic components are mounted. By...

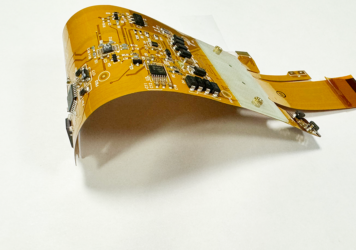

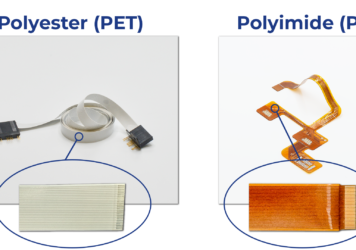

Flexible Printed Circuit (FPC) Dielectric Materials: Choosing the Best for Your Application

At PICA Manufacturing Solutions (PMS), we specialize in creating Flexible Printed Circuits (FPCs) that enable innovative designs by conforming...

Printed Circuit Board (PCB) Via Protection: Strategies and Standards

This blog is an introduction to a larger white paper that features 7 different via protection types. Download the full white...

Enhancing Polyimide Surface Properties for Superior Bonding in Flexible Printed Circuits

The general scope of this article is to discuss methods for treating and characterizing the surface of Kapton, a...