Embedding Performance: How Passive Components Are Integrated into Flexible Circuits

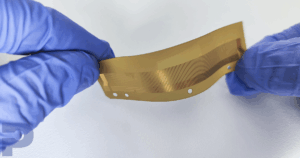

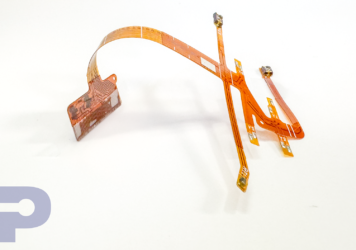

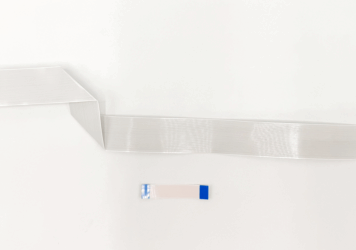

Mona Ni2025-07-29T13:11:28+00:00As electronic devices evolve to become smaller, smarter, and more power-efficient, engineers are under increasing pressure to maximize performance within minimal space. One innovative solution gaining traction is the use of embedded passive components—resistors, capacitors, and inductors that are built directly into the layers of a flexible printed circuit (FPC).

At PICA Manufacturing Solutions, we help engineers implement embedded passive strategies that reduce component count, improve reliability, and shrink device footprints—all without compromising performance.

What Are Embedded Passives?

Embedded passives are circuit elements—typically resistors and capacitors—that are fabricated directly into the inner layers or dielectric material of a PCB or flexible circuit. Rather than placing discrete components on the surface, designers use printed inks, laser trimming, or specialized materials to create these components as part of the board structure itself.

This technique is especially beneficial in flexible circuitry, where space is limited and design efficiency is critical.

Benefits of Embedded Passive Components in Flex Circuits

Why embed passives rather than placing them traditionally on the board?

• Smaller footprint – Eliminate bulky surface-mounted components

• Improved reliability – Fewer solder joints = fewer failure points

• Lower parasitics – Reduced inductance and capacitance improves high-speed performance

• Streamlined assembly – Fewer pick-and-place steps and reduced BOM

• Enhanced mechanical durability – More uniform surface for folding or dynamic flexing

These benefits make embedded passives a powerful design strategy—especially when weight, space, and signal integrity are at a premium.

Common Embedded Passive Techniques

There are several methods to embed resistors and capacitors in a flexible circuit:

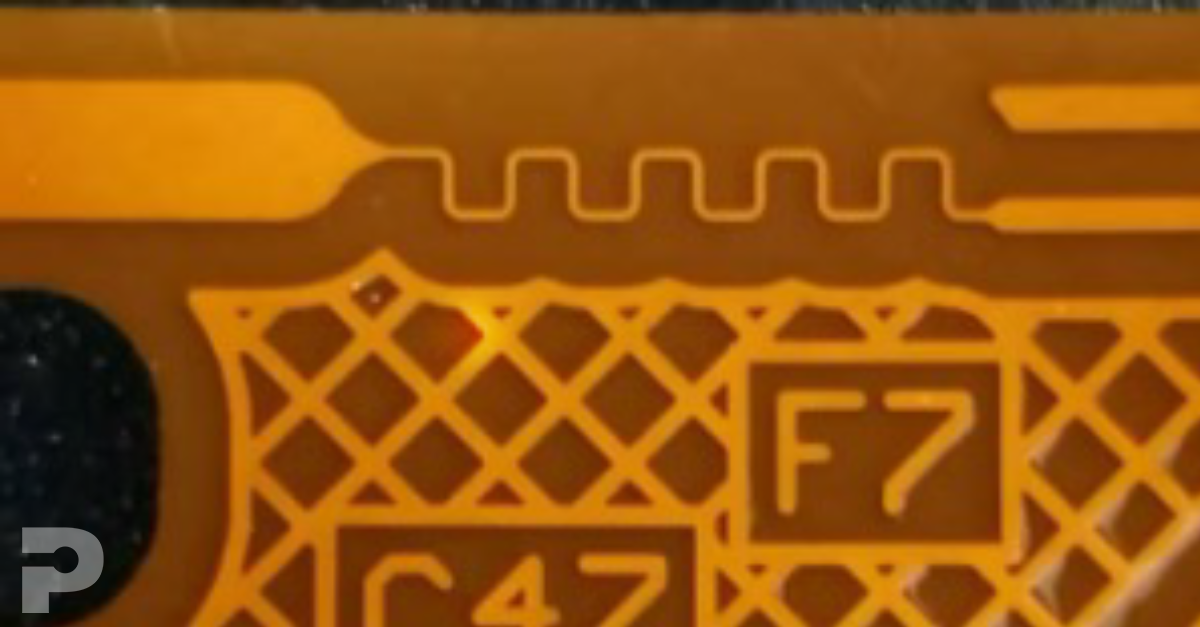

• Printed Polymer Thick-Film Resistors

Conductive inks are screen-printed onto the circuit layers, then cured to form precision resistors. These are often laser-trimmed to exact values.

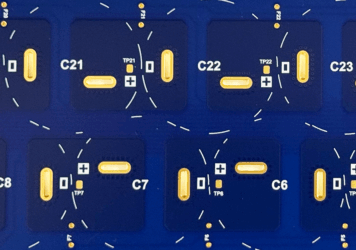

• Embedded Capacitance Materials

Thin, high-Dk dielectric layers (such as 3M C-Ply or DuPont Interra) can provide distributed capacitance between power and ground planes, acting like embedded decoupling capacitors.

• Laser-Trimmable Embedded Resistors

Resistor foils or inks can be adjusted post-fabrication with lasers to meet tight tolerances—ideal for analog or RF designs.

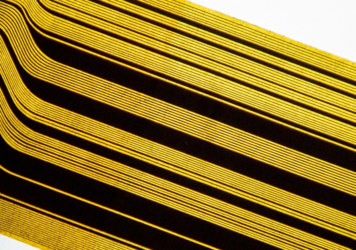

• Layered Conductor Patterns

Certain inductors and resistors can be created using spiral traces or specific conductor geometries, particularly in multilayer flex or rigid-flex builds.

Ready to Streamline Your Flex Circuit Design?

Connect with PICA’s engineering team to explore how embedded passive components can reduce your footprint, improve reliability, and boost performance in your next project.

Design & Manufacturing Considerations

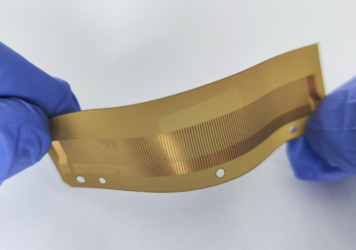

Implementing embedded passives in flex circuits requires careful coordination between design and fabrication:

• Material Compatibility – Not all flex materials support embedded elements; PICA works with specialized dielectric and ink systems designed for flexibility and performance.

• Tight Tolerance Control – Embedded components must meet precise electrical specs—especially for analog, RF, or timing-sensitive circuits.

• Thermal Management – Passive elements must dissipate heat effectively, especially in dense designs.

• DFM Collaboration – Our engineering team can help model and simulate embedded passives for optimal placement, value, and performance.

Where Embedded Passives Make the Biggest Impact

Embedded passive technology can be found in a wide range of applications where space and signal performance are critical:

• Consumer Electronics & Wearables

Smartphones, tablets, and smartwatches benefit from reduced height profiles and improved battery life with fewer discrete passives.

• Medical Devices

Implantable and diagnostic tools rely on compact designs and ultra-reliable circuitry that benefits from fewer solder joints.

• Aerospace & Military

High-density sensor arrays and mission-critical systems require shock resistance, high signal integrity, and lightweight design.

• Automotive Electronics

ADAS, power modules, and infotainment systems gain reliability and reduced board complexity with embedded resistors and capacitors.

• Industrial & Robotics

Embedded components in flex circuits help improve EMI performance and reduce failure points in dynamic robotic joints and machinery.

Why PICA for Embedded Passives in Flex Circuits?

At PICA, we’ve built a reputation for high-precision flexible circuit manufacturing—and that includes expertise in advanced embedded technologies.

Here’s what we bring to your project:

1. Specialized Materials – We work with trusted suppliers of printable resistor inks, embedded capacitance dielectrics, and high-Dk materials.

2. Precision Process Control – From ink printing to laser trimming, we ensure every embedded element meets your electrical specs.

3. Simulation & Testing – We use advanced modeling tools and in-house test equipment to validate embedded component performance.

4. Bend-Ready Engineering – Designs are optimized for real-world movement and flexing, without degrading embedded component function.

Whether you’re building a next-gen wearable, a compact medical probe, or a high-frequency flex sensor array, we can help you reduce complexity and improve performance with embedded passive design strategies.

If your design needs to go smaller, faster, or more reliable, let’s explore how embedded passives can get you there.

Connect with PICA’s engineering team to discuss embedded solutions tailored to your application.