Advanced Trace Routing Techniques for Flexible PCBs: Boost Reliability and Performance

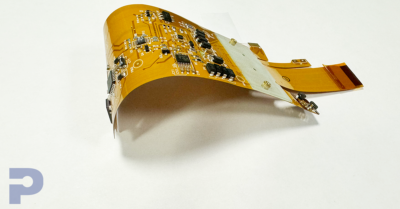

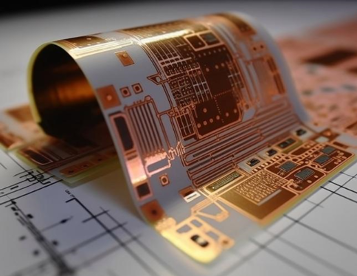

Vivian Zhu2025-09-02T14:53:50+00:00Designing a flexible PCB is not just about taking the layout practices from rigid boards and applying them to a bendable surface. Trace routing, the way copper pathways are arranged, has a direct impact on electrical performance, mechanical reliability, and long-term manufacturability. Poor routing choices can cause impedance mismatches, cracked copper, or premature failure when the circuit undergoes repeated bending. With the right strategies, however, flex PCBs can deliver both performance and durability.

The Challenges of Routing Flexible Circuits

Unlike rigid boards, flexible circuits must withstand both electrical and mechanical stress. Dynamic bending creates fatigue, especially if traces are routed with sharp corners or discontinuities. Compact device footprints demand creative routing that does not compromise impedance control. Material stack-ups, including dielectric thickness and copper adhesion, influence how traces perform under stress. On top of this, shrinking geometries for high-speed applications require careful attention to signal integrity. These challenges make flex routing a specialized discipline that goes well beyond conventional PCB design.

1. Bending Fatigue Mitigation

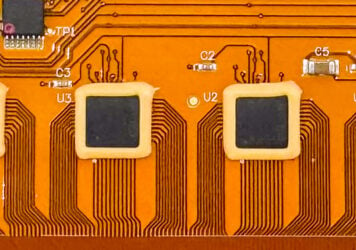

Use perpendicular conductor routing to bending axis (90° angle minimizes tensile stress)Maintain minimum bending radius ≥10× board thickness (e.g., 1mm for 0.1mm thick boards)Implement gradual transitions with 45° dual angles or ≥1.5mm R-corners.

2. Stress Distribution Optimization

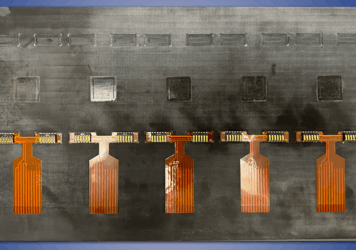

Employ serpentine routing in flex zones (1mm pitch, 0.5mm amplitude) to absorb stressIncrease conductor width by 20-30% in bending area. Use PI reinforcement (0.1-0.2mm thick) in high-stress regions.

Ready to take your flex PCB designs to the next level?

Partner with PICA Manufacturing Solutions to apply advanced routing strategies that enhance reliability, signal integrity, and long-term performance.

Smarter Routing Techniques

Several proven strategies can extend the life and performance of flex circuits. Smooth, curved traces distribute strain far more evenly than sharp corners, which tend to concentrate stress and eventually crack. When traces cross a bend, routing them perpendicular to the bend axis prevents excessive stretching and compression. Keeping trace widths uniform helps avoid both impedance disruptions and stress concentrations.

In high-density designs, staggering vias and traces across layers distributes mechanical strain and reduces weak points. For high-speed signals, impedance control becomes critical, and wider trace spacing or careful use of reference planes can stabilize signal paths. Instead of using solid copper planes, cross-hatched planes preserve flexibility while still offering shielding and return paths. It is also important to give traces extra clearance near rigid-to-flex transitions, which are common areas of mechanical stress. Finally, when routing high-current paths, wider or parallel traces combined with stiffeners can reduce both resistance and heat buildup.

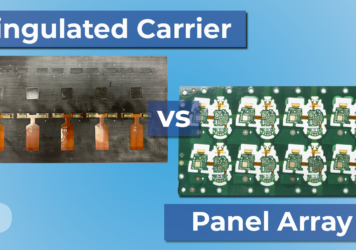

Best Practices Beyond the Layout

The physical design is only one piece of the puzzle. Setting clear CAD rules for bend radii, trace widths, and spacing helps avoid errors early in the design process. Simulation tools can predict copper fatigue before a board is ever built. Collaboration with your fabricator ensures that routing strategies align with manufacturability, and mechanical bend testing during prototyping validates designs under real-world stress.

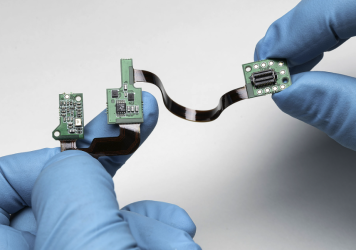

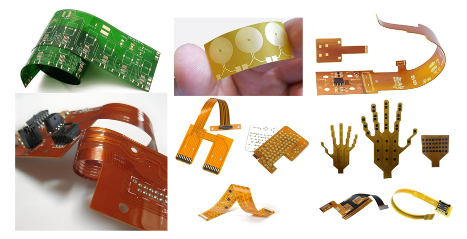

Where Advanced Routing Delivers Results

Wearable devices depend on ultra-thin circuits that can flex thousands of times without failure. Medical devices rely on carefully routed traces for sensors that must be both miniature and biocompatible. Automotive applications such as ADAS modules and EV battery systems often use rigid-flex assemblies where durability and performance cannot be compromised. Aerospace systems leverage flexible routing for lightweight circuits that maintain precise signal integrity.

Final Thoughts

Advanced routing is what separates a flex PCB that merely functions from one that performs reliably over its entire lifespan. With careful attention to trace geometry, impedance, and mechanical stress, engineers can design circuits that withstand real-world demands. At PICA Manufacturing Solutions, we work closely with customers to apply these best practices from the earliest stages of design, ensuring that every flex PCB is optimized for long-term success.