What Is Box Build Assembly? Process, Benefits & How to Choose a Manufacturer

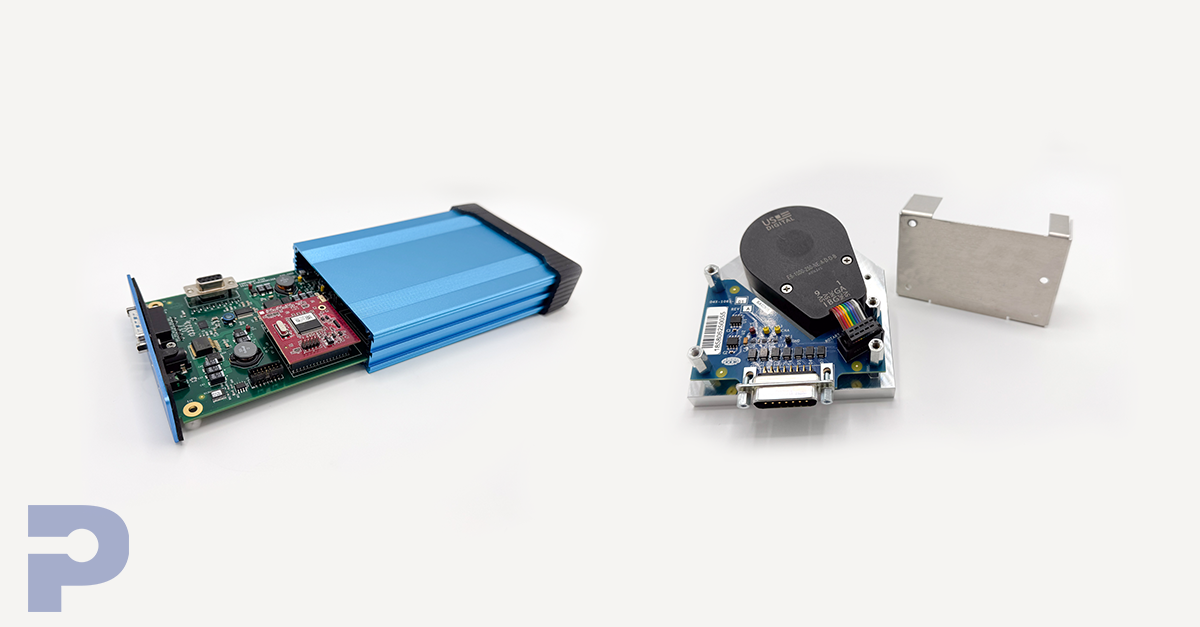

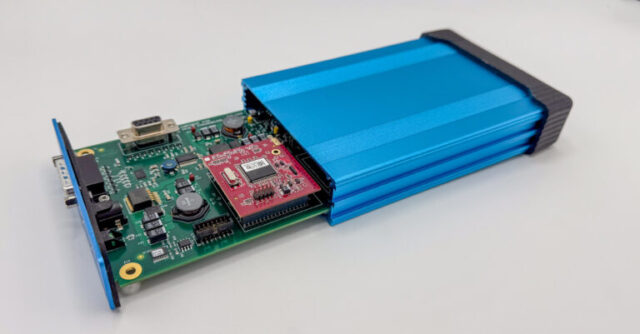

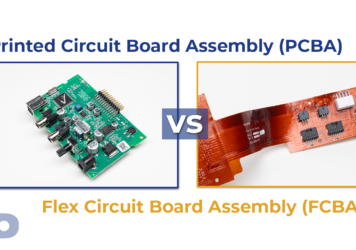

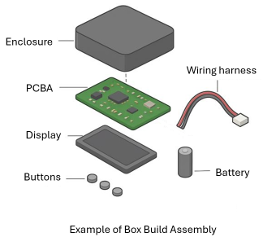

Rafiee Abd Rashid2026-01-20T17:48:29+00:00Box build assembly—sometimes called systems integration—involves assembling a complete electronic product by combining a finished PCBA with wiring, connectors, mechanical components, enclosures, firmware loading, labeling, and final testing. While PCB assembly creates the electronic heart of a device, box build assembly transforms it into a fully integrated unit ready for use, shipment, or final packaging. For many companies developing medical devices, industrial controls, IoT hardware, sensors, or consumer electronics, box build is one of the most important stages in bringing a product to market.

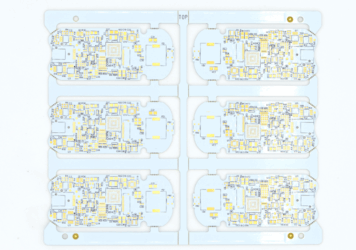

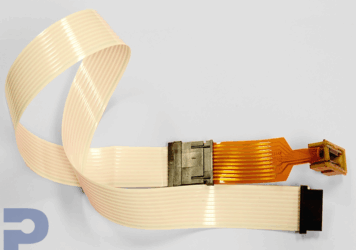

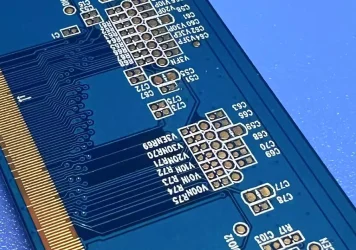

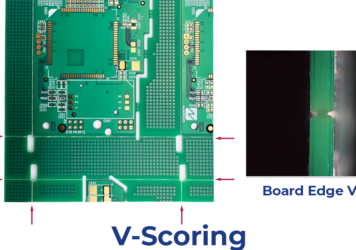

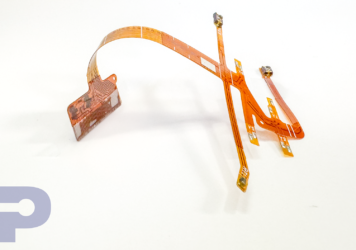

At its core, box build assembly integrates all electronic and mechanical elements into a complete system. This can include cable and wire harness routing, installing subassemblies, mounting PCBs into housings, securing fasteners, adding displays or interfaces, bonding flexible circuits, loading firmware, and completing functional and safety tests. The scope of work varies widely depending on product complexity—from simple enclosed PCB assemblies to multi-board, multi-cable, fully built devices with environmental sealing and regulatory compliance requirements.

Common Steps in the Box Build Assembly Process

• Integration of PCBAs and flexible circuits into enclosures

• Wiring harness routing, crimping, and termination

• Mechanical installation of panels, fasteners, connectors, and hardware

• Firmware loading, calibration, or sensor setup

• Functional, electrical, and sometimes environmental testing

• Labeling, marking, serializing, or packaging for shipment

Looking for a reliable box build partner?

Contact us to discuss your product, requirements, and production goals.

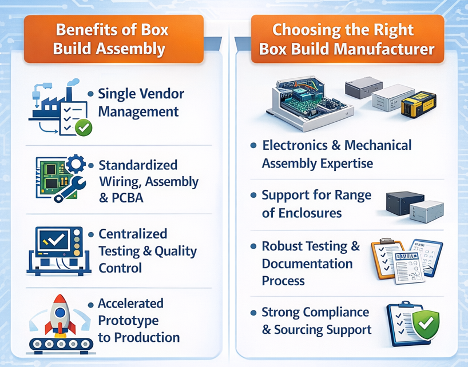

For companies evaluating turnkey solutions, box build assembly provides significant advantages over managing PCB assembly, wiring, enclosure manufacturing, and testing separately. A single manufacturer can manage sourcing, documentation, quality control, assembly processes, and verification steps in one workflow. This reduces handoffs, improves repeatability, shortens lead time, and minimizes the risk of misalignment across vendors. It also creates a clearer path from prototype to production, especially for medical or regulated products where consistency and documentation are critical.

Choosing the right partner for box build is more than evaluating basic assembly capability. Manufacturers must understand system-level requirements, connector strategies, grounding and shielding considerations, test methods, and the interplay between mechanical and electrical design. The best partners support design for manufacturability (DFM), help refine documentation, identify risks early, and ensure that the final assembly is both buildable and reliable at scale.

Why Companies Choose Turnkey Box Build Assembly

• Reduces vendor coordination and simplifies supply chain management

• Ensures consistent quality across wiring, mechanical assembly, and PCBA integration

• Streamlines testing and verification under a single controlled process

• Supports accurate builds for medical, industrial, and IoT hardware

• Accelerates transition from prototype to production

When selecting a box build manufacturer, consider their experience across both electronics and mechanical assembly, the range of enclosure types they support, their testing capabilities, and how well they manage documentation such as BOMs, wiring diagrams, CAD files, and test procedures. Engage early to confirm whether they can assist with compliance requirements, component sourcing, scaling volume, and long-term production support. The right partner doesn’t just assemble devices—they enhance manufacturability, improve reliability, and help bring your product to market faster.

Box build assembly is ultimately about delivering fully integrated electronic systems that perform consistently and can move seamlessly into field use or final packaging. By understanding the process and selecting a manufacturer with strong engineering and integration expertise, companies can ensure dependable final assemblies and a smoother product development cycle from start to finish.