PICA Manufacturing Solutions Biosensors Market

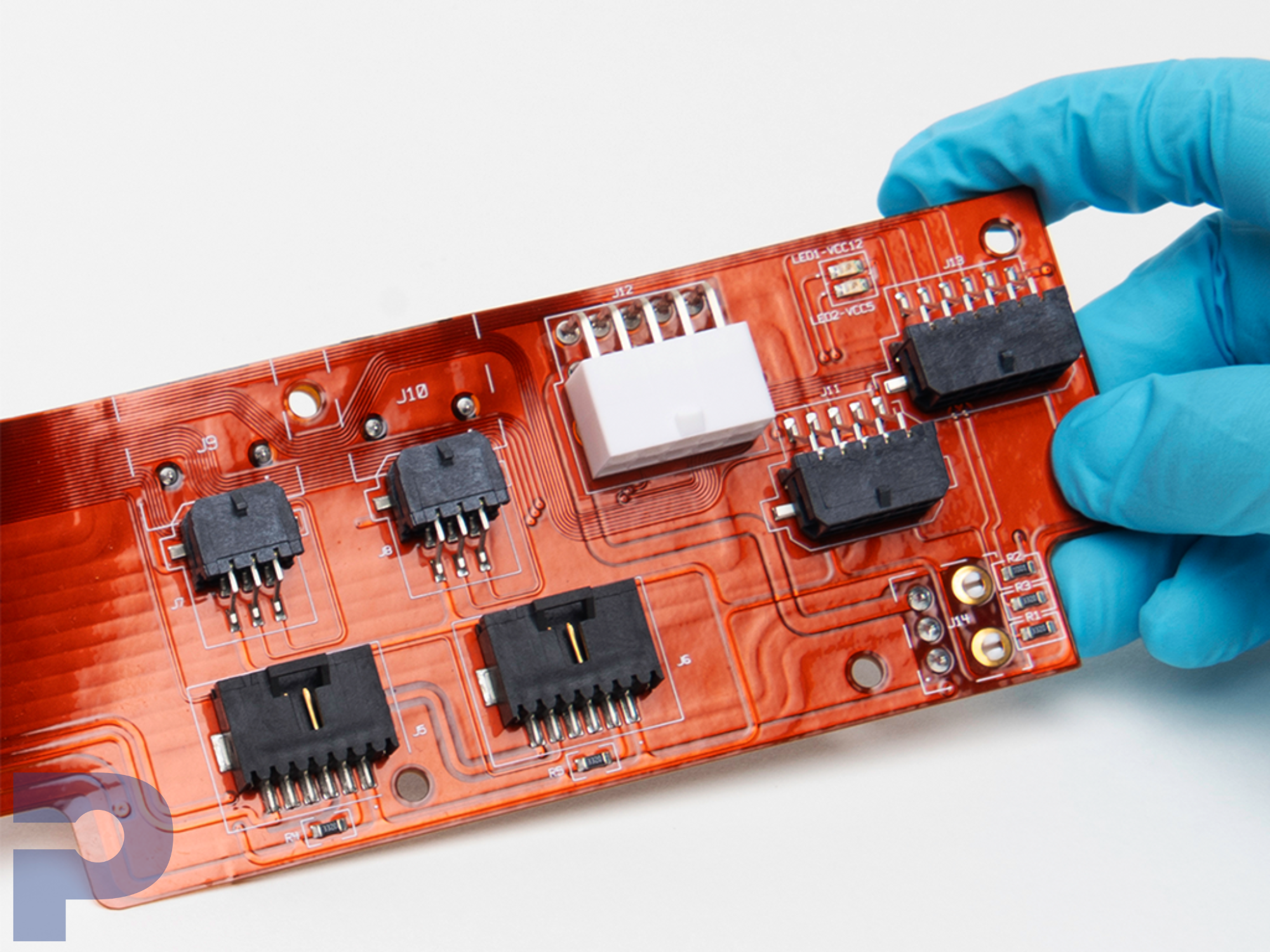

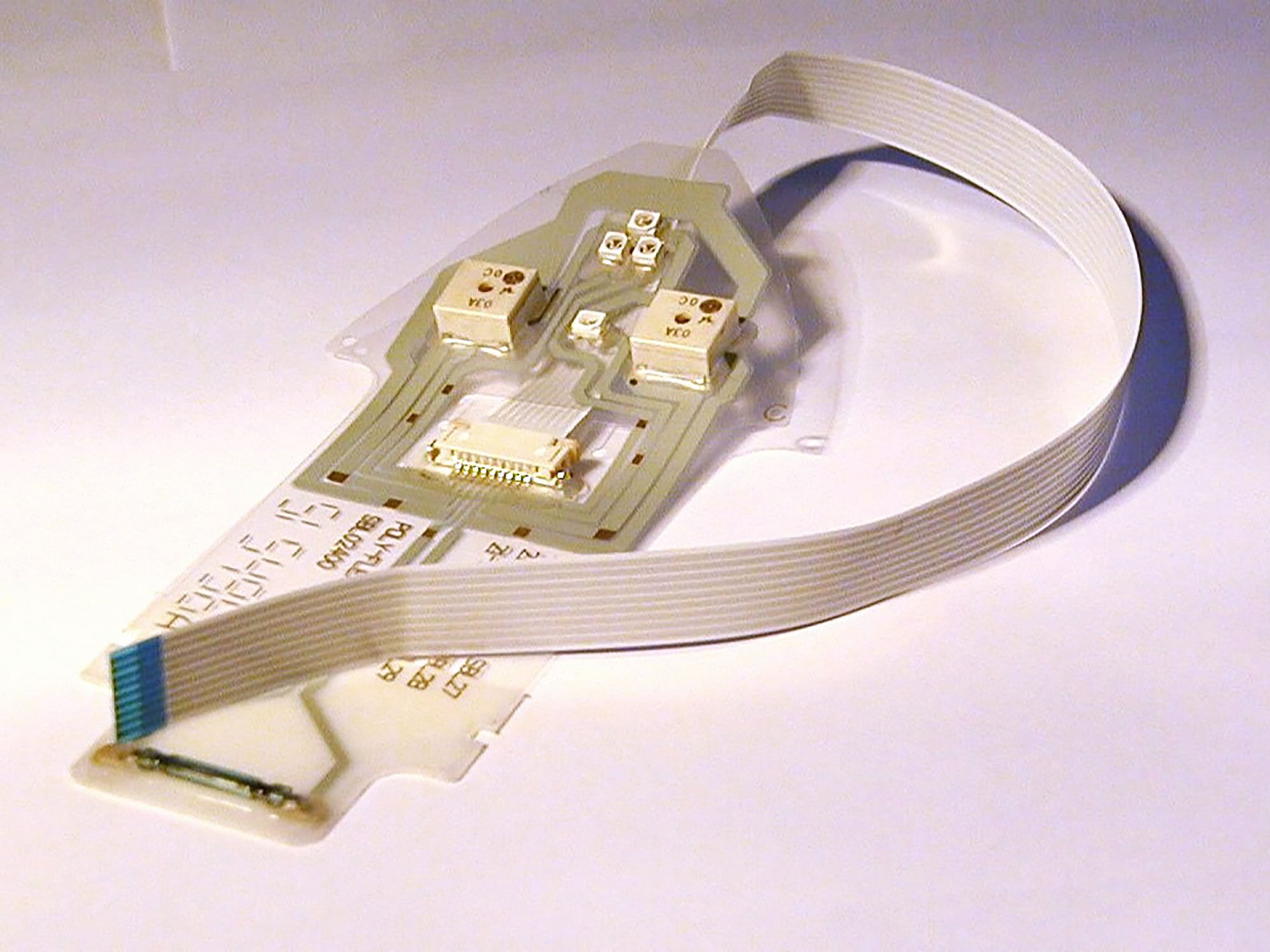

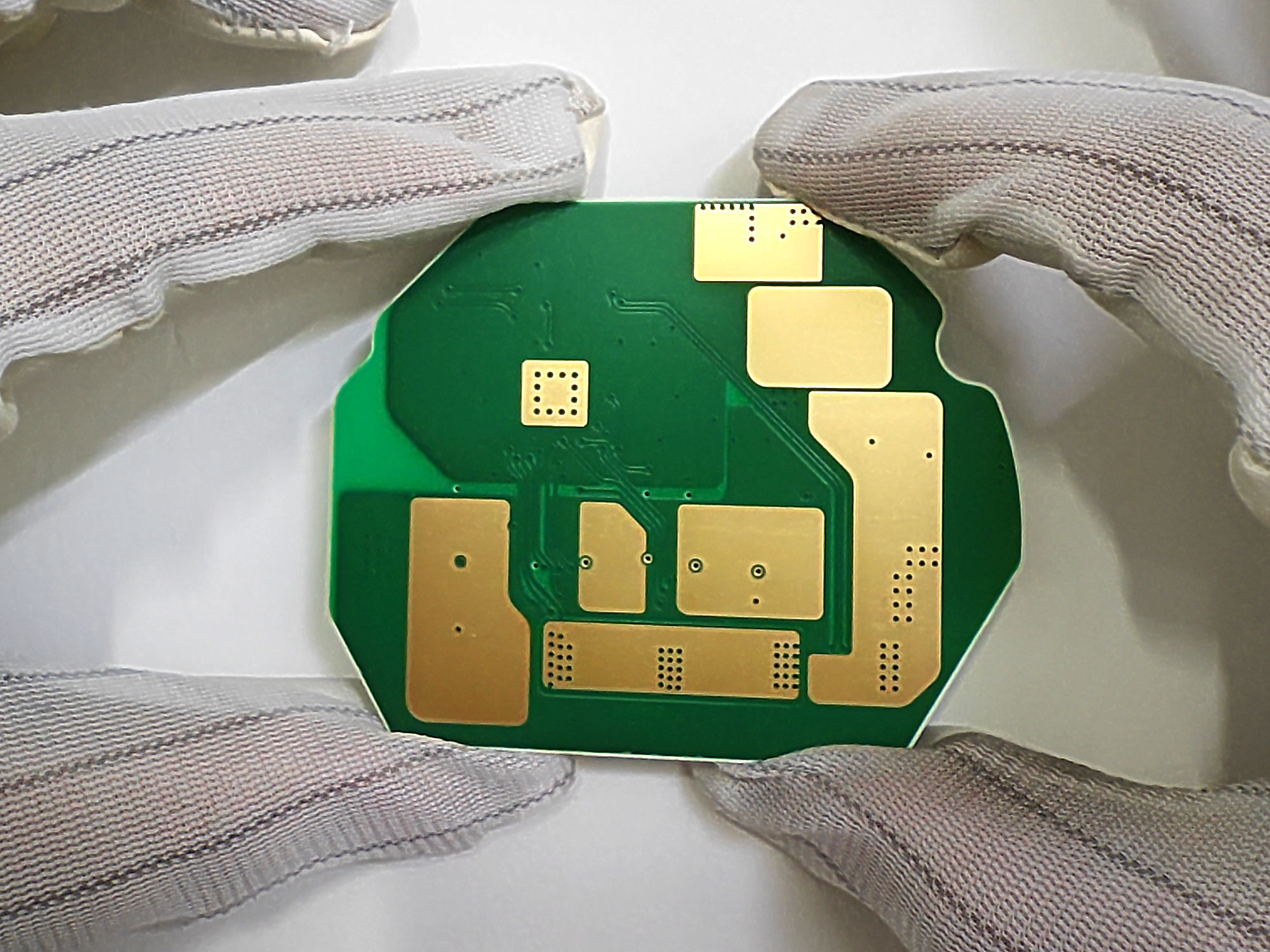

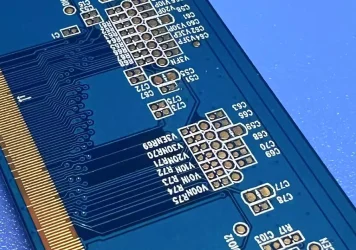

PICA Manufacturing Solutions produces high-sensitivity, reliable flex and rigid PCBs for biosensor applications—whether disposable, semi-reusable, or designed for rapid scale-up. Our expertise in precision manufacturing supports accurate detection, contamination resistance, and consistent performance in health, environmental, and safety monitoring devices.

We enable innovation across a broad spectrum of submarkets:

Wearable Body Analyzers

Our PCB solutions for compact biosensing devices are built for accuracy and durability in small form factors, whether designed for single use or extended operation. We focus on clean manufacturing to reduce contamination risk and maintain measurement integrity.

Environmental Biosensing

From toxin detectors to food safety monitors, environmental biosensors depend on consistent electrode surface quality. PICA controls flex and rigid PCB electrode surface roughness to optimize antibody and bioreceptor deposition, improving detection accuracy and minimizing copper oxidation risks.

From wearable health monitors to environmental analysis equipment, PICA delivers the high-precision flex and rigid PCB technology that ensures biosensors perform consistently, accurately, and at scale.

Partner with PICA for high-performance PCB solutions that bring accuracy, reliability, and scalability to your biosensing technology.

Guide to PCB & FPC Manufacturing Processes

This blog is an excerpt from the white paper Guide to PCB & FPC Manufacturing Processes: Subtractive, Semi-Additive & Additive...

Conductive Inks and Their Role in Flexible and Printed Electronics

Conductive Inks and Their Role in Flexible and Printed ElectronicsAs electronics continue to evolve beyond rigid, boxy enclosures, the materials...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...