Designing for Precision: Controlled Impedance in Flexible Circuits

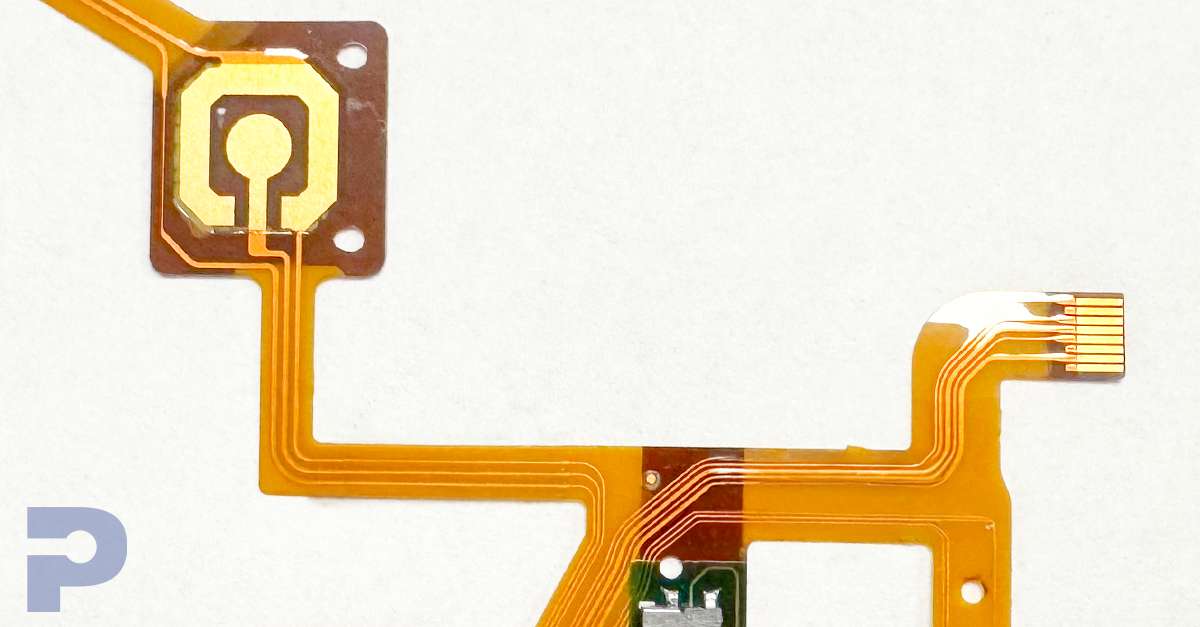

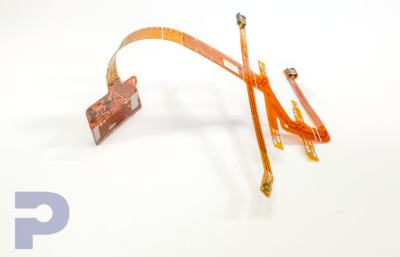

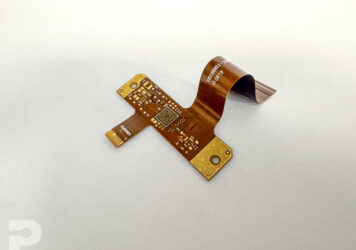

Sara Hu2025-08-11T15:03:29+00:00As electronic devices shrink and signal speeds increase, one design requirement becomes mission-critical: controlled impedance. This is especially true in flexible circuits—where mechanical and electrical performance must coexist in tight, dynamic spaces.

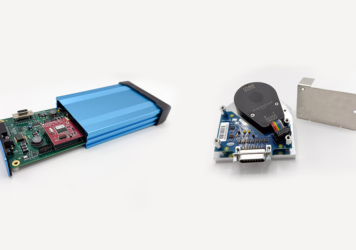

At PICA Manufacturing Solutions, we help engineers design and build flexible and rigid-flex PCBs that deliver signal integrity, even under bending and high-speed data demands. Here’s what you need to know about controlled impedance in flex design—and why it matters across industries.

What Is Controlled Impedance—and Why Does It Matter?

Controlled impedance ensures that high-speed signals travel through a PCB/FPC/FFC without distortion, delay, or interference. This is achieved by precisely defining the electrical resistance (usually 50Ω for single-ended or 100Ω for differential pairs) between a signal trace and its return path.

In rigid boards, maintaining controlled impedance is straightforward. But in flexible PCBs, it’s more complex. The materials bend. The layer counts are lower. The dielectric thicknesses are thinner. Yet the expectations for signal performance remain the same.

Key Design Factors for Controlled Impedance in Flex Circuits

To achieve consistent impedance, engineers must carefully control several parameters:

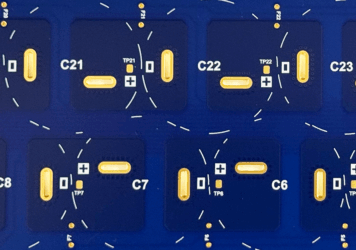

• Trace Width & Spacing: The width of signal lines and distance between differential pairs directly affects impedance.

• Dielectric Thickness & Material (Dk): Polyimide is often used in flex circuits, but its dielectric constant and thickness must be controlled within tight tolerances.

• Copper Thickness: Heavier copper changes impedance and can limit flexibility.

• Ground Planes: Solid or cross-hatched ground planes are used as return paths, but must be designed to balance electrical performance with bendability.

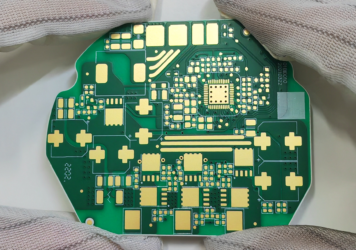

• Layer Stack-Up: Whether it’s microstrip (2-layer), stripline (3+ layers), or embedded designs, stack-up design plays a key role in managing impedance.

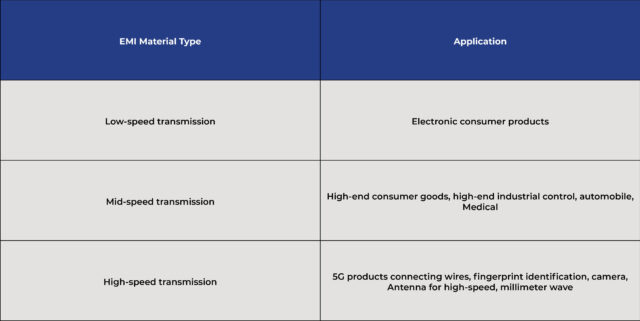

• EMI Material Type: Different EMI materials have different performance implemented at different applications (low-speed transmission, mid-speed transmission and high-speed transmission).

At PICA, we model all of these factors to create stack-ups tailored to your performance and assembly needs.

Common Flex Stack-Ups for Controlled Impedance

• 2-Layer Microstrip: Ideal for lightweight, bendable designs with basic signal requirements.

• 3-Layer Embedded Microstrip: Signal trace embedded between dielectric and ground layers for more EMI protection.

• Stripline Configurations: Provide the most shielding and consistent impedance but increase rigidity—best for hybrid or rigid-flex applications.

Ensure flawless signal integrity in your next flex design—partner with PICA for precise controlled impedance solutions.

Precision Manufacturing & Testing at PICA

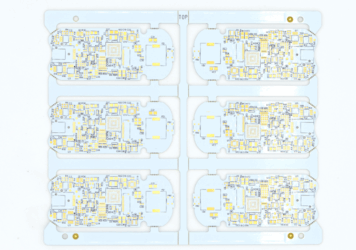

Controlling impedance requires more than just good design. Manufacturing must be equally precise:

• Optimal Etch Compensation: Ensuring trace widths and spacing

• Tightly Controlled Lamination: Ensuring uniform dielectric spacing

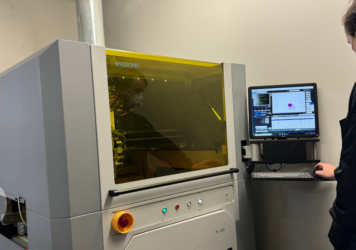

• Advanced AOI (Automated Optical Inspection): Verifies trace widths and spacing

• TDR (Time Domain Reflectometry): Validates impedance performance before shipment.

Our engineering and quality teams work closely with you to ensure your impedance targets are met from concept to completion.

Where Controlled Impedance in Flex Circuits Makes the Biggest Impact

Controlled impedance isn’t just a design preference—it’s essential for reliable performance in today’s high-speed, space-constrained electronics. At PICA, we support industries where signal clarity is non-negotiable:

Medical Devices

• Wearable patient monitors

• Imaging probes and catheters

• Implantable telemetry systems

These applications demand small form factors with precise signal performance, often under dynamic movement or heat.

Aerospace & Defense

• Avionics and navigation systems

• Rugged sensor networks

• Tactical communication equipment

Controlled impedance ensures mission-critical signals are clear, fast, and immune to interference in harsh environments.

Automotive & EV Systems

• Radar and camera systems

• In-vehicle infotainment and data buses

• Battery management and power delivery

Modern vehicles use high-speed digital interfaces and FPCs to reduce weight while maintaining performance under vibration and temperature swings.

Consumer Electronics & IoT

• Smartphones and tablets

• Smartwatches and fitness bands

• Connected home and industrial IoT

Flex circuits allow compact, curved form factors with tightly packed signal paths—requiring careful impedance control to prevent crosstalk and signal loss.

Industrial & Robotics

• Automated inspection systems

• Machine vision

• Factory sensor networks

Flexibility and durability are key in moving or rotating equipment, but signal reliability cannot be compromised.

Why Engineers Choose PICA for Controlled Impedance Flex Circuits

At PICA, we provide:

Full-stack expertise – From DFM reviews to stack-up modeling

Precision processes – Tight material and etching tolerances

Advanced inspection – TDR, AOI, and impedance validation

Flexibility-focused engineering – Designs that bend, but don’t break signal performance

Whether you need a single-ended flex circuit or a multilayer rigid-flex with differential pairs, we partner with you to deliver signal consistency and mechanical reliability in every build.

Ready to Control Your Signals?

Let’s talk about your next high-speed flex or rigid-flex project. Our engineers are ready to review your design and help optimize it for performance, manufacturability, and cost.