Case Studies That Prove Performance

Featured Case Studies

We at PICA Manufacturing Solutions support select research and academic programs when time and capacity allow because advancing science and medicine starts with reliable hardware. We partner with university teams and labs to help design and build flexible, rigid, and rigid-flex PCBs that meet demanding performance requirements, from high-density routing and signal integrity to durability in challenging environments. Whether you need early design guidance, material and stackup recommendations, or a complete build path from prototype to assembly, our engineer-backed team works alongside your researchers to turn complex concepts into manufacturable, dependable circuitry so your project can move forward with confidence.

Vivo Recording and Optogenetics

A UC San Diego research team needed a reliable interconnect to link a main electronics board to a sensor board in a tight mechanical envelope, while maintaining a slim profile, high-density routing in a narrow flex width, and continuous flexing during operation. PICA delivered a double-sided flexible printed circuit using rolled annealed copper on an adhesiveless base laminate with button plating, plus turnkey support including design, fabrication, and assembly of the two board connectors.

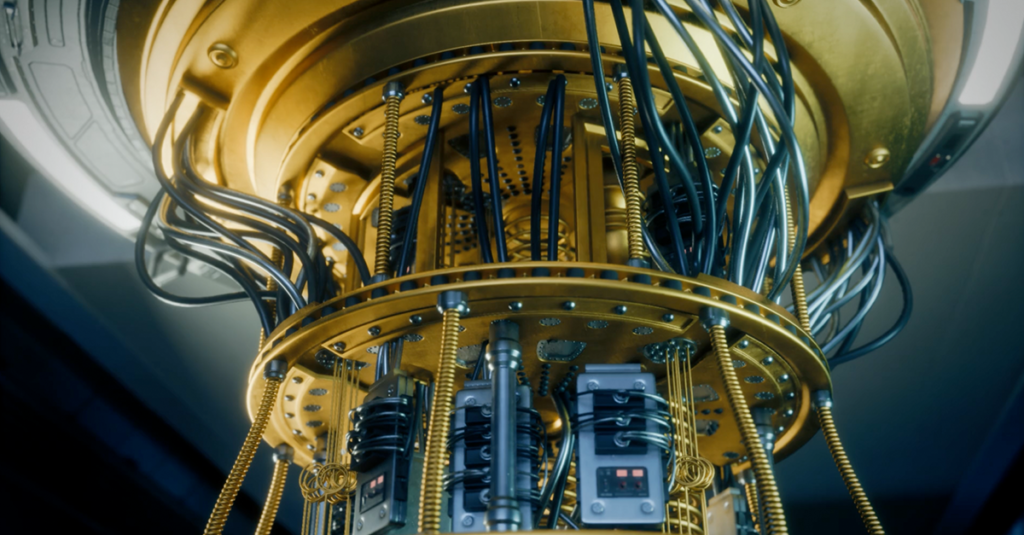

Cryogenic Electronics Research Case Study

Université de Sherbrooke led project evaluated fully adhesiveless flex circuits as an alternative to wiring harnesses in quantum computing cryostats operating below 4 Kelvin. The goal was to reduce thermal loading, improve stability during thermal cycling, and enable higher-density interconnects, while supporting high-speed differential signaling with 100 ohm controlled impedance routing. Initial evaluations showed feasibility, with cryogenic validation planned under representative conditions.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Flex PCB Substrate Deep Dives Beyond Polyimide

PET vs PEN, LCP, PTFE/fluoropolymers, and specialty films like PEI/PEEK: when each wins, where each struggles, and what it means...

Highlights from MD&M WEST 2026

MD&M West 2026 in Anaheim brought together medtech, automation, design/manufacturing, plastics, and packaging, so the biggest trend wasn’t one...

Tariffs in the United States: History, Reality, and How PICA Helps You Navigate Them

Tariffs have played a role in the U.S. economy since the nation’s founding. In the early days of the republic,...

CES 2026 Highlights: The Breakthrough Technologies Powered by Advanced Flex & PCB Design

Las Vegas, January 2026 — CES 2026 once again confirmed that the pace of innovation in consumer tech, mobility,...