Box Build Assembly & Turnkey Solutions

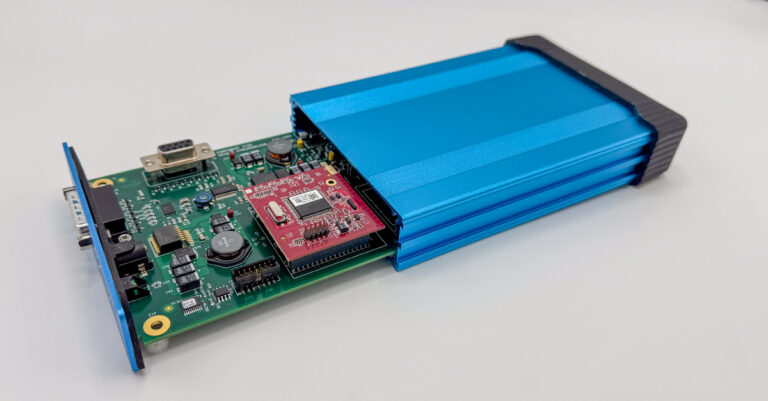

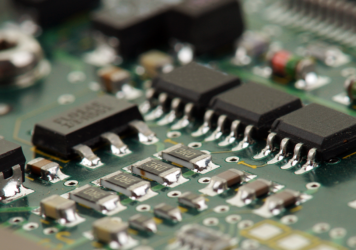

PICA delivers turnkey box build assembly that takes your project from circuit to finished product. Instead of managing multiple vendors, we integrate PCB assembly, wiring harnesses, enclosure installation, final mechanical build and testing under one controlled manufacturing process. Our engineering-driven approach reduces handoffs, improves reliability, and accelerates timelines from prototype through full production.

Whether you’re building medical wearables, industrial controls, IoT devices, or specialized consumer electronics, our box build manufacturing ensures consistent results across every unit. We combine PCBA, wiring, mechanical integration, labeling, packaging, and final product qualification to deliver production-ready systems that meet functional, cosmetic, and compliance requirements.

Our turnkey box build assembly supports low- to mid-volume custom builds as well as scalable manufacturing for high-volume programs. Early engagement with our engineering team helps align design files, enclosure requirements, connector strategies, wiring layouts, test procedures and documentation to ensure predictable performance and smooth production transitions.

PICA’s box build solutions also provide clear advantages over PCB-only assembly. By controlling wiring, interconnect strategies, component routing, enclosure fit, and testing in one process, we reduce variability and improve repeatability. For regulated and safety-critical designs, our structured documentation and quality controls help ensure compliance and product consistency.

For companies searching for turnkey box build assembly or full product integration, PICA provides a single manufacturing partner that understands system-level requirements. From PCB and flex assembly through wiring, enclosure installation, and final validation, our box build capabilities deliver dependable electronic systems ready for deployment.

Benefits of Box Build Assembly & Turnkey Solutions

End-to-End Integration – Combines PCB assembly, wiring, enclosures, and software into a single, fully tested system.

Streamlined Supply Chain – One trusted partner reduces the need for multiple vendors, saving time and resources.

Accelerated Time-to-Market – Integrated processes and expert engineering shorten production cycles.

Improved Quality – Centralized assembly, inspection, and testing ensure consistency and compliance with standards.

Cost Efficiency – Reduces overhead by consolidating sourcing, assembly, and logistics into one seamless solution.

Scalable Manufacturing – From prototypes to high-volume turnkey builds, production adapts to project needs.

Box Build Capabilities (Highlights)

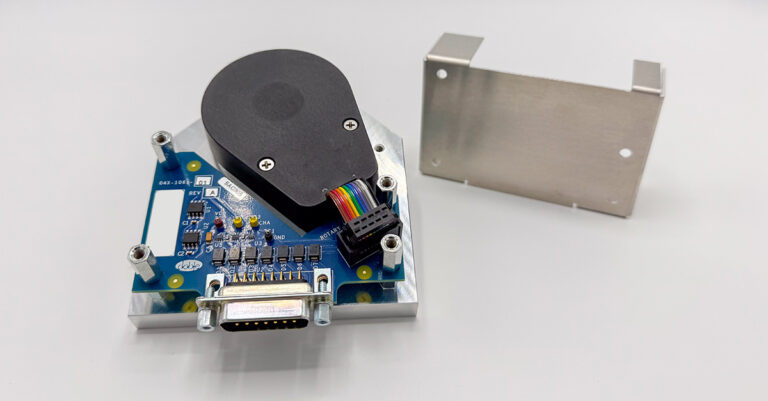

System-Level Integration

Complete box builds combining PCBs, subassemblies, enclosures, and wiring into turnkey products for faster time-to-market.

Enclosure & Subassembly Assembly

Precise builds of submodules and customer-supplied enclosures with reliable fit, finish, and performance.

Cable Routing & Wire Harness

Clean, efficient routing and harness assembly to improve reliability and serviceability.

Testing & Quality Assurance

Custom functional and power-up testing, visual inspection, and strict ESD controls ensure dependable performance.

Thermal & Environmental Protection

Epoxy, encapsulation, and potting services safeguard electronics from vibration, moisture, and harsh conditions.

Traceability & Compliance

Lot tracking, serialized labeling, and tailored documentation to support regulated industries.

Manufacturing Support

DFM reviews, fixture design, and flexible sourcing models (including consignment) reduce risk and cost.

For more technical information on PICA's Box Build and Turnkey capabilities, click the button below.

Benefits of Box Build Assembly & Turnkey Solutions

Simplified Supply Chain Management: By going to one supplier the supply chain is reduced and thus allows the OEM to focus instead on their core competencies.

Faster Time to Market: The assembly process is streamlined and done by experts and thus reducing greatly the time to market. Everyone is focused on what they are best at.

Improved Quality Control: By entrusting the assembly to experts with experience and quality systems the final product is more likely to meet high-quality standards.

Reduced Overall Costs: Due to increased expertise and efficiency the price of outsourcing the bob builds is reduced.

Markets of Box Build Assembly & Turnkey Solutions

Medical Devices

Box build solutions for diagnostic instruments, monitoring systems, and portable medical devices requiring high reliability and compliance.

Automotive & Transportation

Turnkey assemblies for control units, infotainment modules, and power systems built to withstand rugged environments.

Industrial Systems

Integrated builds for robotics, automation equipment, and process controls where durability and precision matter.

Consumer Electronics

End-to-end builds for smart home systems, computing devices, and audio/visual electronics requiring efficiency and scale.

Defense & Aerospace

Ruggedized assemblies for avionics, mission-critical electronics, and secure communications requiring traceability and durability.

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

Compliance: Ensuring Safety and Performance in Flexible Printed Circuit Manufacturing

When developing and manufacturing flexible printed circuits (FPCs), adhering to industry standards ensures reliability, safety, and performance. Two pivotal standards...

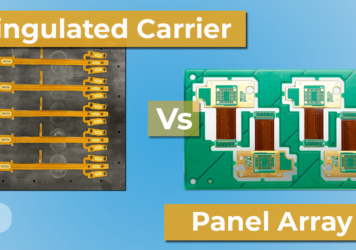

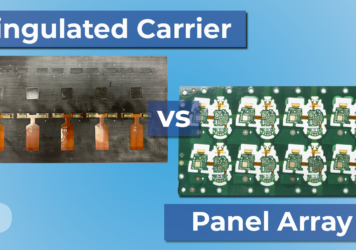

Navigating SMT Assembly Methods for Flexible Circuits Part 2

Part 2: Comparing Panel Array vs. Singulated Carrier AssemblyIn the first part of this series, we explored the key considerations...

Navigating SMT Assembly Methods for Flexible Circuits

This blog is the first in a two-part series that delves into the critical factors you need to consider when...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advance Soldering Techniques for Printed Circuit Board Assembly

Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy,...

Why X-Ray inspection is essential in flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA) processes

In the realm of flexible printed circuit assembly (FPCA) and printed circuit board assembly (PCBA), X-ray inspection...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.