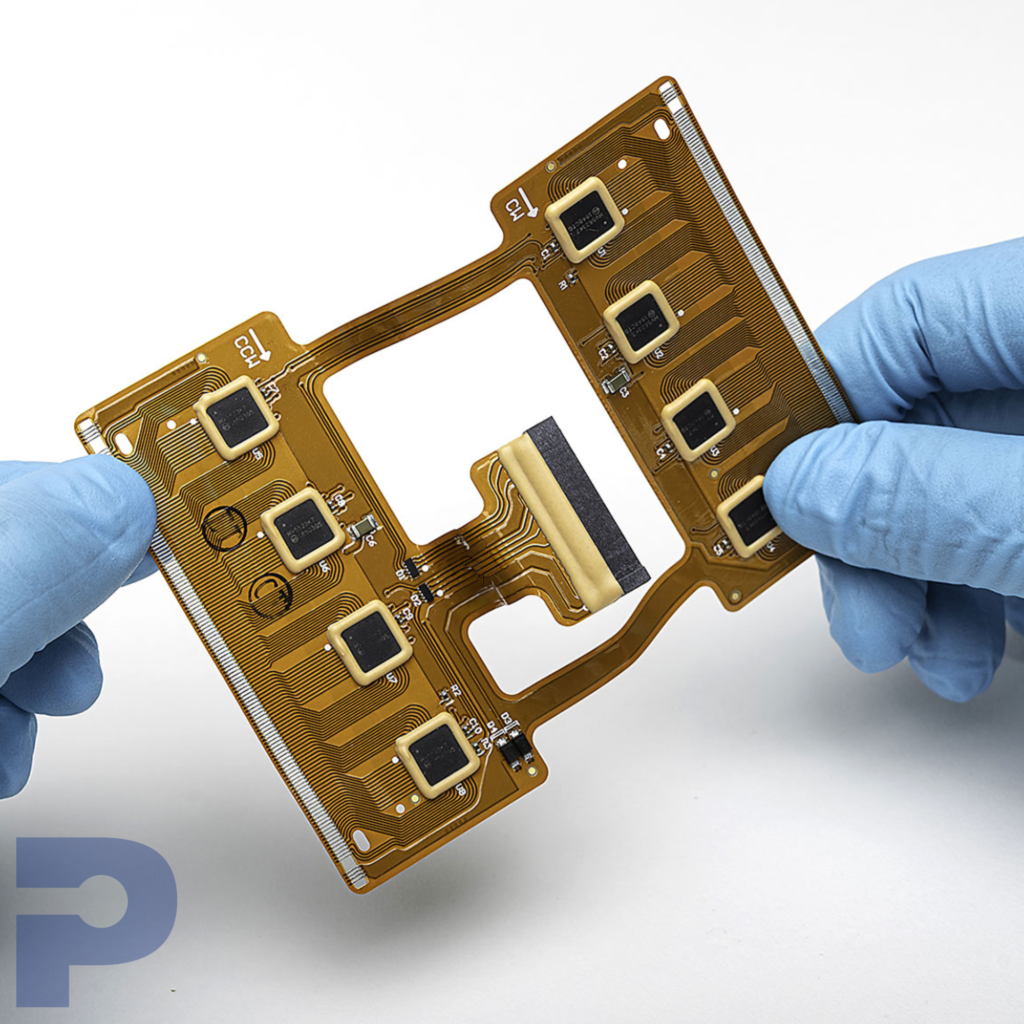

Flexible Circuit Boards / Flex PCB:

Custom Flexible Circuit Boards Designed for Performance

PICA designs and manufactures Flexible Circuit Boards / Flex PCBs engineered for reliability, miniaturization, and high-performance applications. Built from advanced polyimide and polyester materials, our flex circuits bend, twist, and fold to fit the most compact or irregular spaces — without sacrificing durability.

With fast turnaround, expert DFM support, and global delivery, PICA helps design engineers push the limits of what’s possible in medical, automotive, defense, aerospace, industrial, and consumer electronics.

Why Choose Flexible Circuit Boards?

-

Space-Saving Design – Perfect for compact or irregular spaces, enabling thinner, lighter, and more efficient devices.

-

Enhanced Reliability – Fewer connectors and cables mean fewer failure points.

-

Superior Durability – Withstands vibration, shock, and repeated bending better than traditional rigid boards.

-

Lightweight Construction – Reduces overall system weight, critical for portable and aerospace applications.

-

Design Versatility – Supports three-dimensional configurations and creative layouts rigid boards can’t achieve.

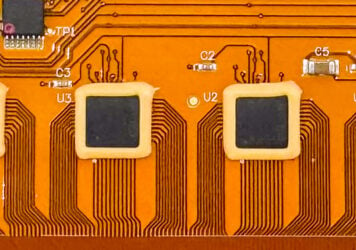

Flexible PCB Capabilities - Highlights

PICA combines advanced materials and manufacturing techniques to support today’s most demanding designs:

Up to 40 rigid layers and 32 flex layers

2 mil (50 μm) trace/space for high-density designs

Controlled impedance with TDR testing & verification

Ultra-thin adhesiveless polyimide laminates

EMI shielding (Ag ink, copper plane, and EMI film)

High-frequency and high-power design options

For more technical information on PICA's Flexible Printed Circuit Board capabilities, click the button below.

Global Support, Fast Turnaround

With facilities in both the U.S. and Malaysia, PICA provides flexible circuit manufacturing with responsive engineering support, global logistics, and scalable production capacity. Whether you need prototypes, high-volume roll-to-roll production, or complex rigid-flex builds, our team delivers speed and reliability.

Benefits of Flexible Circuit Boards / Flex PCB

Space Efficiency

Flex circuits are uniquely suited for compact and irregular spaces, making it easy to optimize limited real estate within modern electronic devices. Their adaptability allows them to conform to unconventional shapes and configurations.

Reliability

By reducing the need for connectors and interconnect cables, flexible printed circuits minimize failure points and improve overall device reliability.

Durability

Engineered to withstand vibration, shock, and repeated bending, flexible PCBs are ideal for harsh operating environments where traditional rigid boards often fail.

Lightweight Design

The light construction of flex PCBs helps reduce overall device weight — a key advantage in portable electronics, aerospace, and wearables.

Design Freedom

Flexible PCBs enable true three-dimensional layouts. They can bend, fold, and twist, giving engineers more freedom to create innovative, space-saving designs not possible with rigid boards.

Markets We Serve with Flexible Circuit Boards / Flex PCBs

Consumer Electronics Market

Flexible PCBs are critical in smartphones, tablets, wearables, and other portable devices. Their thin, lightweight design enables compact layouts while improving durability and reliability in daily use.

Medical Market

From pacemakers and implants to hearing aids and diagnostic systems, PICA’s flex circuits deliver miniaturization, biocompatibility, and reliability for life-critical medical technologies.

Automotive Market

Our flex PCBs are engineered for control systems, sensors, lighting, and infotainment. Their vibration resistance and ability to conform to vehicle contours make them ideal for modern automotive electronics.

Industrial Market

In robotics, automation, and advanced sensors, flexible printed circuits provide space savings, rugged durability, and lightweight performance in demanding industrial environments.

Defense & Aerospace Market

Flex circuits are trusted in satellites, avionics, missiles, and defense electronics. Their durability under extreme stress, vibration, and temperature ensures mission-critical reliability.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Why You Should Involve Your Flex Circuit Manufacturer Early in the Design Process

In product development, timing is everything. But too often, the flexible circuit comes late in the conversation,...

Flexible Circuits Powering the Next Generation of Drones

Modern drones demand electronic systems that are lightweight, compact, and highly reliable. Traditional rigid PCBs often struggle to...

Roll-to-Roll Processing: Driving the Next Generation of Flexible Circuits

Electronics are shrinking, getting lighter, and expected to perform flawlessly in demanding environments. From medical

Using Flex Circuits to Design Smaller, Smarter Electronics: The Smartphone Advantage

From the palm of your hand, smartphones have revolutionized how we connect, work, and navigate the world. But behind the...

Environmental Resilience in Flex PCB Design

Part 1: High-Temperature Flex Circuit Design – Engineering for Heat Resistance

In aerospace, automotive, industrial,...

Biocompatible Substrates for Flex and Rigid PCBs

In the expanding world of medical devices, and wearables, the demand for biocompatible substrates...

Advanced Trace Routing Techniques for Flexible PCBs: Boost Reliability and Performance

Designing a flexible PCB is not just about taking the layout practices from

Mastering Thermal Management in PCB and Flex Circuit Design

As electronic devices become more compact and powerful, managing heat effectively is critical to ensuring performance, reliability, and long product...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.