At PICA, we deliver advanced Metal Core Printed Circuit Board solutions engineered for high-power and thermal-demanding applications. Below are our capabilities across Materials, Thermal Performance, Stack-Ups, and Manufacturing Processes. For detailed specifications on surface finishes, design guidelines, and tolerances, please request the full MCPCB Capabilities PDF using the form below or click the button to connect with a PICA engineer.

Technology

- Max. 4 Layers

- Single-sided Aluminum substrate size max. 500×1230 mm

- Single-sided copper substrate size max. 500 mm

- Thermoelectric separation of copper substrate size max. 300×350 mm

- Min. Board Thickness: 0.40 mm (0.0157 inch)

- Max. Board Thickness: 4.0 mm (0.157 inch)

- Copper thickness 1-20 oz

- Minimum solder mask dam 0.10 mm (.004 in) (1 oz copper)

- Minimum SMD pad size 0.40 mm

- Punching, Routing, V-cut

Materials

- RoHS Compliant, UL 94 V-0 Approved

- Thermal Conductivity 1.0 to 20W/m.k

- PICADJ, TCB-2AL, BOYU, HA80, VT-4B3, NRK, 3D Bending, etc. aluminum base

- Copper base

- White, green, black solder mask; high reflection white solder mask

Interconnect

- Copper IMS Plating Insulation Hole

- Copper IMS With Isolated Thermal Pad – Single Sided

- Copper IMS With Isolated Thermal Pad – Double Sided

- Aluminum IMS PTH Insulation Hole

Surface Finishing

- HASL, Lead free HSL, OSP, Immersion Gold, Immersion Silver

Patterns & Holes

- Space & Trace: 0.10mm (.004 in) (1 oz copper)

- Through hole size: 0.80mm~6.50mm

- Countersunk; maximum drill bit size: 8.3mm

Laminate Shear and Drill

| Product Process | Project | Process Capability | ||||

|---|---|---|---|---|---|---|

| Laminate Shear |

Board Thickness | 0.4-0.8mm | 1.0-1.6mm | 1.7-2.0mm | 2.1-4.0mm | |

| Board Tolerance | ±0.05mm | ±0.075mm | ±0.10mm | ±0.12mm | ||

| Panel Size |

|

Aluminum array | Max length is 1.2m, but when length >600mm, width size must be <333mm |

|||

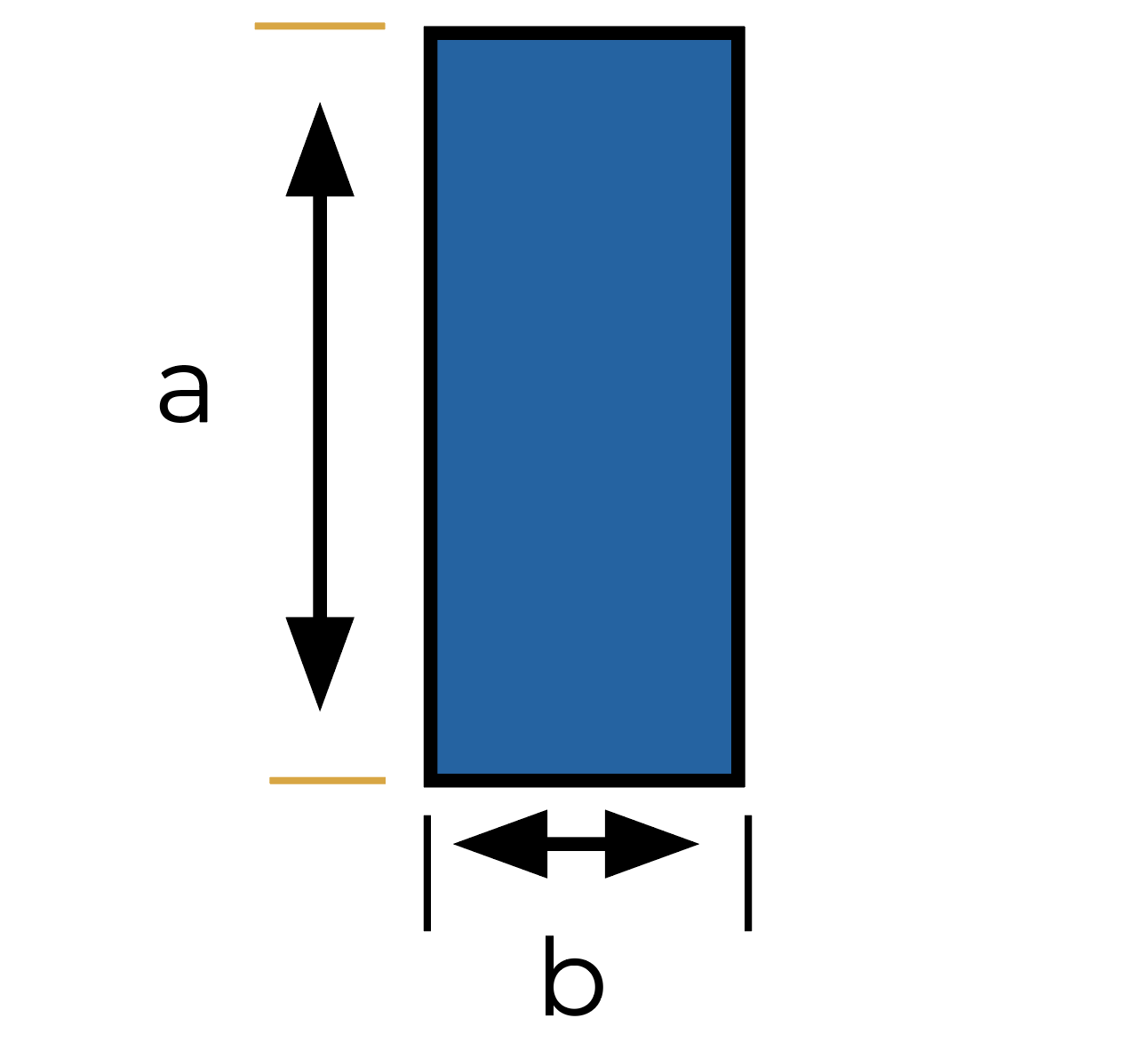

| AL plate panel | a≥500mm, b≤300mm | |||||

| Copper substrate panel | Copper substrate panel size 500x600mm Max Thermoelectric separation of copper substrate panel size 300x350mm Max |

|||||

| Working panel size |

|

CNC Routing | 7.5mm≥a and b≥5mm | |||

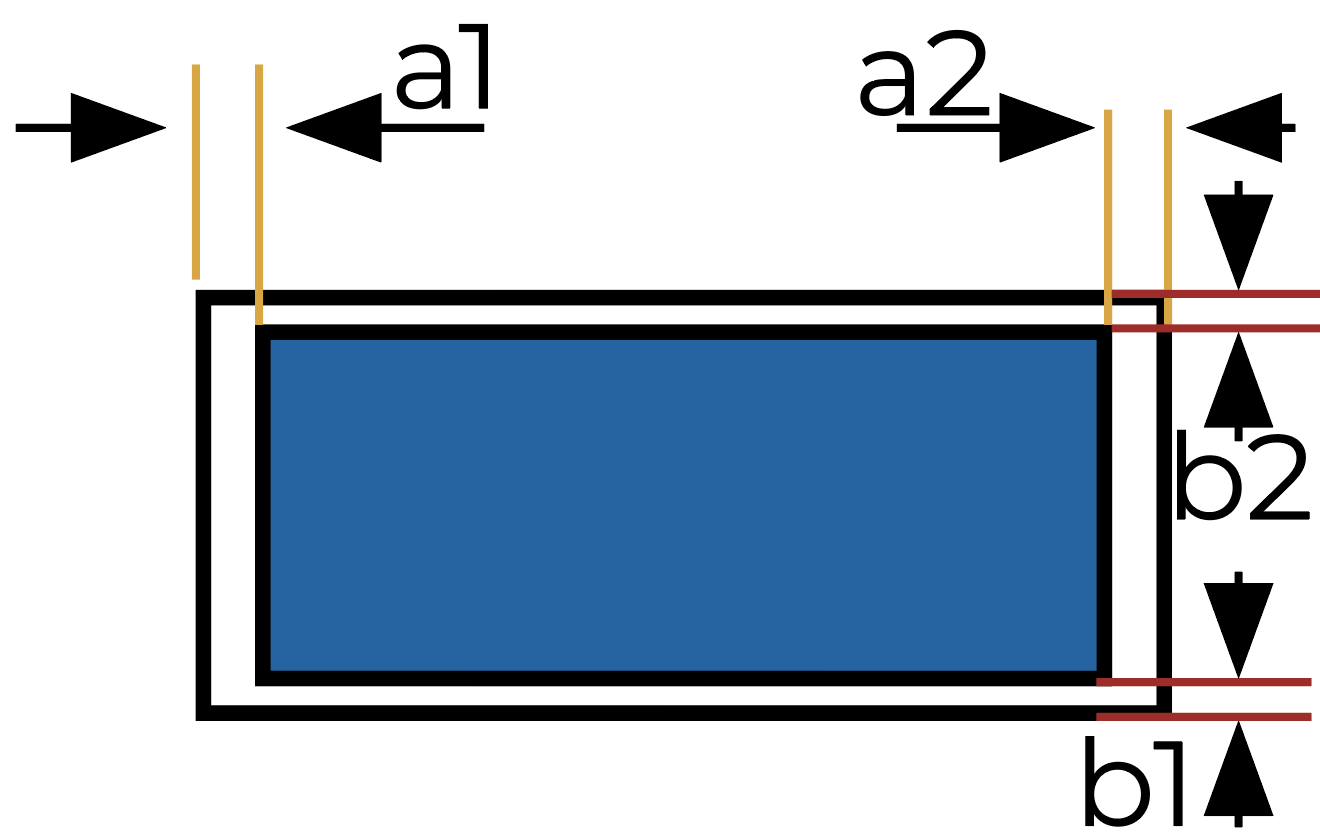

| V-cut | 11mm≥a and b≥5mm a1+a2≤18mm, b1+b2≤18mm |

|||||

| Laminate Shear Tolerance | +/-1mm | |||||

| Drill | Drill position tolerance | ≥0.05mm | ||||

| Hole to Hole | ≥0.1mm | |||||

| Hole Size Tolerance | Single Fr4 | ±0.05mm | ||||

| Single AI | ±0.05mm | |||||

| Double-sided AI and Copper substrate board | PTH/1 oz/2 oz | ±0.05mm | ||||

| NPTH | ±0.05mm | |||||

Drill and Electrical Circuit

| Product Process | Project | Process Capability | |

|---|---|---|---|

| Drill | Max Drill bit size | Drill bit size: Ø5.5mm; counter sink: Ø8.3mm | |

| Min Drill bit size | Board thickness<1.6mm: Ø0.8; board thickness≥1.6mm: Ø1.0 | ||

| Countersunk | Hole DIA ±0.05mm | ||

| Angle ±°5 | |||

| Counter sink DIA ±0.2mm | |||

| Counter sink depth ±0.2mm | |||

| Max working panel size | 1200x350mm; 500x600mm | ||

| Hole wall roughness | ≤0.025mm | ||

| Electrical Circuit | Width/Distance | Cu Thickness | min width/distance |

| 1 oz | 0.10mm/0.10mm | ||

| 2 oz | 0.25mm/0.25mm | ||

| Line to routing edge | CNC routing | 0.3mm | |

| V-cut | ≥0.4mm and no less than 1/3 of board thickness | ||

| Registration accuracy | ≥0.05mm | ||

| Circuit to hole edge | ≥0.2mm (Min) | ||

| Exposure size | 1200x500 (Max) | ||

| Circuit compensation | Cu Thickness | Compensation value | |

| 1 oz | 0.03mm | ||

| 2oz | 0.05mm | ||

| Character width | 1 oz: a≥0.2mm, b≥1.0mm; 2 oz: a≥0.3mm, b≥1.2mm | ||

Solder Mask and Silkscreen

| Product Process | Project | Process Capability | ||

|---|---|---|---|---|

| Solder Mask | Registration accuracy | ≥ 0.075mm | ||

| Ink width min | Cu Thickness | Ink width | ||

| 1 oz | 0.15mm | |||

| ≥ 2 oz | 0.2mm | |||

| Solder Mask Opening | NPTH hole window is smaller than hole diameter by 0.1mm on each side | |||

| Solder pad to circuit | ≥ 0.2mm | |||

| Solder mask side light exposure | Green | ≤ 25µm | ||

| White | ≤ 25µm | |||

| Black | ≤ 38µm | |||

| Ink Thickness | ||||

| Large copper land | 20-25µm | |||

| Circuit corner | ≥10µm | |||

| Gridding width | 1 oz | ≥ 0.2µm | ||

| 2 oz | ≥ 0.25µm | |||

| Character width | On copper land | ≥ 0.2mm | ||

| On laminate | ≥ 0.25mm | |||

| Silkscreen | Silkscreen size | Cu Thickness | Height | Width |

| 1 oz | ≥ 0.75mm | ≥ 0.13mm | ||

| 2 oz | ≥ 1.0mm | ≥ 0.15mm | ||

| Registration accuracy | Silkscreen to PAD ≥ 0.2mm | |||

| Minimum distance of light bar characters from solder: 0.25mm | ||||

Punch, V-Cut, and Other

| Product Process | Project | Process Capability | ||||

|---|---|---|---|---|---|---|

| Punch | Connection trace width | ≥2mm and ≥1.3 x board thickness | ||||

| Minimum hole | ≥Ø2.0mm and ≥1.2 x board thickness | |||||

| Minimum spacing | Board thickness ≤2.0mm, B>1.5mm; board thickness >2.0mm, B>2mm | |||||

| Punch hole to outline | ≥2mm and ≥1.4 x board thickness | |||||

| Hole position tolerance | ≥0.05mm | |||||

| Minimum radius | 0.5mm | |||||

| V-Cut | Minimum V-cut width | ≥120mm | ||||

| Maximum V-cut width | ≤605mm | |||||

| V-cut tolerance | ≥0.1mm | |||||

| V-cut to copper | Board thickness | 0.4-0.6mm | 0.8-1.2mm | 1.3-2.0mm | >2.0mm | |

| Copper to outline | ≥0.4mm | ≥0.5mm | ≥0.6mm | ≥0.7mm | ||

| Other | ||||||

| Maximum measured size | General size | Light bar size | ||||

| 400x650mm | 250x1200mm | |||||

| Flying probe distance | 0.15-0.2mm | 0.15-0.2mm | ||||

| OSP size minimum | 60x60mm | |||||

| OSP Thickness | 0.2-0.5µm | |||||

| Immersion Gold Thickness | NI: ≥120µ", AU: ≥1µ" |

|||||

| HASL Thickness | 2-8µm | |||||

| Plate Silver Thickness | ≥120µ" | |||||

| Immersion Silver Thickness | 0.15-0.3µm | |||||