PICA Manufacturing Solutions – U.S.-Based Electronics Manufacturing With Strategic Operations in Malaysia

Your Engineering-Driven Manufacturing Company in Malaysia

Looking for a trusted manufacturing company in Malaysia to support complex electronics, medical devices, or high-reliability assemblies? PICA Manufacturing Solutions (Malaysia) combines ISO-certified quality, cleanroom production, and hands-on engineering support to help you move from concept to scalable production with confidence.

PICA Manufacturing Solutions (Malaysia) at a Glance

Located in Petaling Jaya, Selangor, within Malaysia’s electronics and manufacturing hub

Over 22,000 ft² of total space with ISO 7 (Class 10,000) cleanroom area, assembly, warehouse, and office areas

Clean, controlled environment designed for high-reliability electronics and medical devices

Growing team of skilled operators, technicians, and engineers

Local manufacturing company in Malaysia backed by PICA’s global engineering and supply-chain network

What We Manufacture in Malaysia

Our Malaysia site integrates with PICA’s U.S. and Asia-based operations to support:

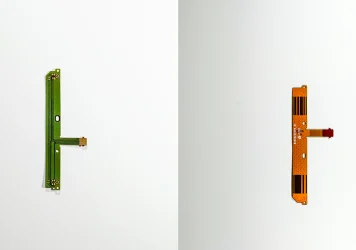

Flexible and rigid-flex printed circuits

Rigid and metal-core PCBs

Medical and wearables assemblies

Sensor modules and sub-assemblies

Turnkey box-builds and final product assembly

Whether you’re prototyping a new medical device or scaling an industrial or automotive platform, PICA Malaysia gives you access to an experienced electronics manufacturing company in Malaysia with strong engineering support, not just production capacity.

Certified Quality & Medical Manufacturing

PICA Malaysia is built for high-reliability and regulated applications. The facility holds:

ISO 9001:2015 – Quality management

ISO 13485:2016 – Medical device quality systems

ISO 14001:2015 – Environmental management

IPC-A-610 – IPC Trainer on staff

These certifications, combined with PICA’s engineering review and DFM support, help reduce risk, speed approvals, and improve long-term product reliability.

Cleanroom & Production Environment

To support sensitive and high-cleanliness assemblies, PICA Malaysia features:

ISO 7 (Class 10,000) cleanroom area (~9,644 ft²) for controlled manufacturing

Dedicated final product assembly area (938 ft²)

Segregated warehouse (3,000 ft²) and component storage

This environment supports medical wearables, biosensor patches, optical assemblies, and other applications where contamination control and process discipline are critical.

Robust Utilities & Capacity to Scale

The facility is designed with built-in headroom so customers can grow without changing partners:

Building equipped with its own substation to support high electricity demand

Air compressors running at ~50% loading, with a spare unit available

Chiller capacity with additional units available when ground-floor expansion is activated

Ground floor space and future cleanroom expansion (up to ~13,993 ft²) defined for growth

For OEMs and design teams, this means your manufacturing company in Malaysia has a clear path to support higher volumes, more lines, and additional processes without disruption.

Digital Transformation & Workforce Development

Beyond equipment and square footage, PICA Malaysia is focused on building a smarter, more capable operation:

• Digital Transformation

We are actively digitizing production data, traceability, and quality records to give customers better visibility, faster feedback, and more reliable process control.

• Workforce Development & Training

Our team invests in structured operator and technician training, IPC certification, and cross-functional skill building to maintain a highly capable workforce that can handle complex builds and continuous improvement.

• Sustainability Initiatives

With ISO 14001 certification, PICA Malaysia manages environmental impact carefully, from utilities usage to waste handling—supporting customers with their own ESG and sustainability goals.

Why Use a Manufacturing Company in Malaysia?

Locating your production with PICA Malaysia offers several advantages:

Strategic location: Easy access to Southeast Asia, with strong logistics routes to the U.S., Europe, and Asia-Pacific.

Cost-effective manufacturing: Competitive operating costs compared to many mature electronics hubs.

Skilled, English-speaking team: Easier communication, better collaboration, and smoother NPI launches.

Stable, ISO-certified supply chain: Balanced across the U.S. and Asia to reduce risk and lead-time volatility.

For many customers, PICA Malaysia becomes the core hub in a multi-region strategy—using Malaysia for volume manufacturing, U.S. operations for engineering liaison, and partner facilities for specialized processes.

Benefits of Our Manufacturing Company in Malaysia

Engineering-Driven Partnership

Our Malaysia team works closely with PICA’s global engineers to review designs, optimize stack-ups, and solve manufacturability issues before they become costly problems.

Cleanroom & Controlled Production

Class 10K cleanroom space and disciplined processes support medical, wearable, and other high-reliability assemblies that demand tight contamination control.

Scalable Capacity

Built-in electrical, HVAC, and floor-space headroom make it easier to ramp from pilot builds to higher volumes without changing manufacturing partners.

Certified Quality Systems

ISO 9001, ISO 13485, and ISO 14001 certifications help ensure consistent quality, traceability, and environmental stewardship across every build.

Global Supply Chain Resilience

PICA Malaysia is integrated with U.S. operations and proven partners in Asia, giving you multiple-region sourcing and reduced supply-chain risk.

Cost-Effective Manufacturing

Competitive operating costs in Malaysia, combined with strong process control, help you balance price, performance, and quality for demanding products.

Markets We Serve from Our Malaysia Facility

Medical & Wearables Market

From biosensor patches to patient monitoring devices, our cleanroom and ISO 13485 systems support life-critical and near-patient medical electronics.

Consumer & Wearable Electronics Market

Compact, lightweight assemblies for smart devices, fitness wearables, and connected consumer products benefit from our flex and rigid-flex expertise.

Automotive & Mobility Market

We support modules for sensors, lighting, control systems, and EV-related electronics that must survive vibration, heat, and long service life.

Industrial & IoT Market

Rugged assemblies for factory automation, robotics, and industrial sensing leverage our durability, reliability, and scalability in Malaysia.

Communications & Networking Market

High-density interconnects and reliable PCB assemblies for networking, telecom, and connected infrastructure are supported by disciplined processes.

Defense & Security Market

For selected programs, our engineering-led, tightly controlled manufacturing environment helps meet demanding reliability and quality expectations.

What to Look for in a Manufacturing Company in Malaysia

When evaluating a manufacturing company in Malaysia, most teams are focused on a few essentials: capability fit, reliable quality systems,...

LPI Solder Mask vs. Polyimide Coverlay: Choosing the Right Protection for Flexible Circuits

Protecting the copper circuitry on a flexible printed circuit (FPC) is essential to ensuring long-term reliability and...

Roll-to-Roll Processing: Driving the Next Generation of Flexible Circuits

Electronics are shrinking, getting lighter, and expected to perform flawlessly in demanding environments. From medical

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...