Guidelines for Consigning Components & PCBs to PICA

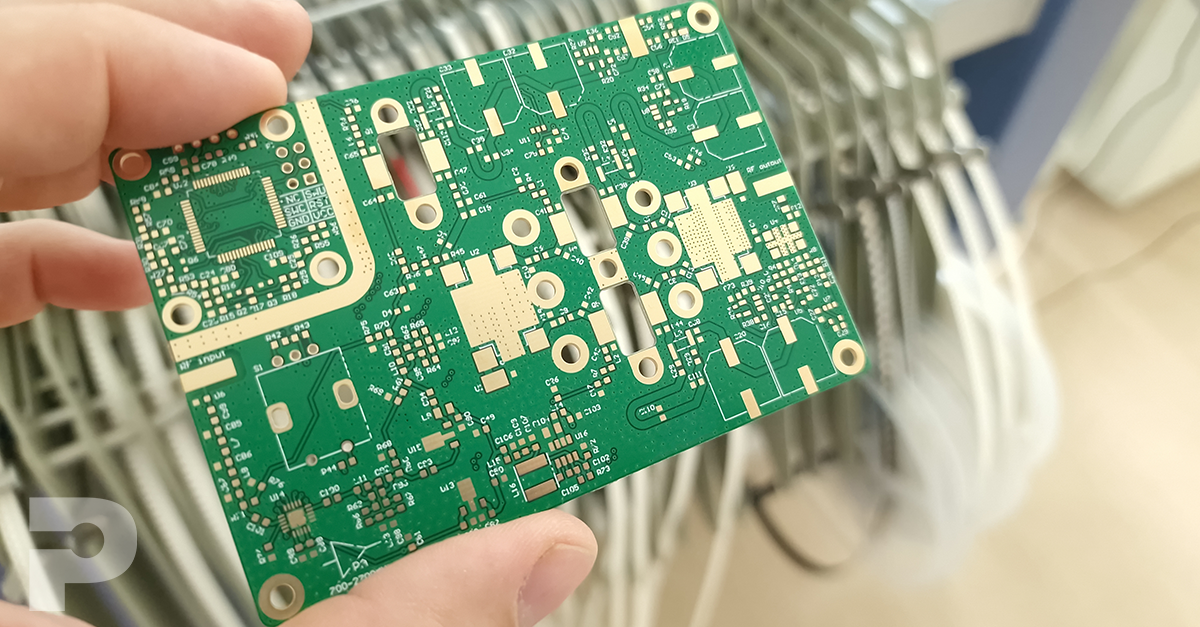

FlexPros2025-09-02T13:42:24+00:00At PICA Manufacturing Solutions, we occasionally receive printed circuit boards (PCBs) and/or components consigned by our customers for their projects. To ensure we can deliver the highest quality service and products, we recommend that customers follow specific guidelines when consigning materials to us. These guidelines are designed to enhance our assembly processes and ensure precision throughout production. This blog details the key requirements and recommendations that help us achieve optimal results in every project involving consigned materials.

- Actual Quantities of Components Supplied

It’s crucial to ensure the actual quantities of components supplied are accurately counted and verified upon receipt. This verification process helps in maintaining the integrity of the production schedule and reduces discrepancies in component inventory.

- Component Quantities Based on 98% Yield

We calculate component quantities based on a 98% yield rate. This accounts for potential defects or assembly issues, ensuring that there are sufficient components available to meet the production demands without unnecessary delays.

- Additional Components Supply

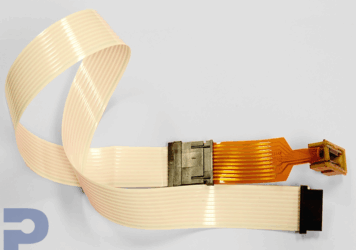

To further mitigate any potential production losses or for testing purposes, we require a supply of 10% more components than the base number calculated or a minimum of 3 inches of continuous tape. This extra provision safeguards against unexpected shortages.

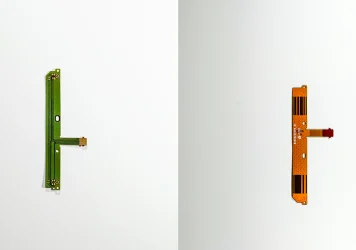

- Continuous Strips for Components Delivery

For enhanced efficiency in our automated pick-and-place processes, components should be delivered in continuous strips instead of individual pieces. This aids in reducing the time and complexity involved in the assembly process.

- Board Quantity Based on 98% Yield

Similar to components, the quantity of PCBs provided should also reflect a 98% yield rate, with a minimum of two extra boards. These additional boards are crucial for compensating for any non-conforming units or for use during the testing phase.

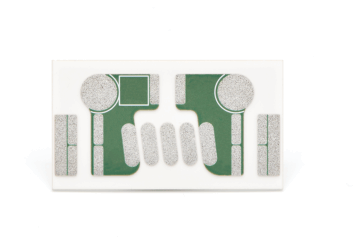

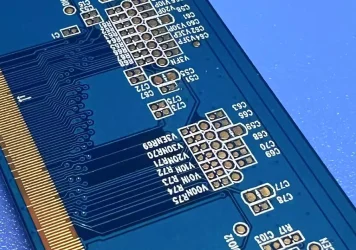

- Fiducials on Parts and Panels

Fiducials are critical for accurate placement and orientation during the assembly:

- Individual Parts: Each part should have fiducials to assist in precise placement.

- Panel (Array): Panels containing multiple parts should include fiducials to ensure proper alignment during the assembly process.

Explore our company profile

Explore PICA Manufacturing Solutions’ history, values, locations, and product offerings. Learn about our quality-first approach and engineering expertise.

- Preferred Fiducial Design

The design of fiducials should consist of 1mm round pad diameters. This size is commonly preferred for its consistency and ease of machine recognition, enhancing the reliability of the assembly equipment.

- Number of Fiducials

A minimum of two fiducials per part is mandatory, though three are typical to enhance the accuracy and reliability of component placement across various production scenarios.

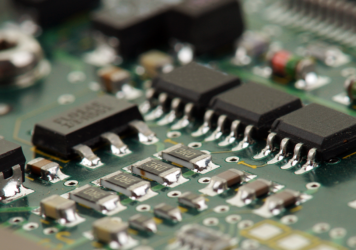

- Soldermask Between Component Solder Pads

Applying a soldermask between component solder pads is essential to prevent solder bridging. This ensures a clear delineation of connection points on the PCB, crucial for maintaining the functionality and integrity of the circuit.

- Panel Use Over Singulated Parts (primarily for Rigid PCB)

Whenever possible, PCBs should be provided in panel form rather than as singulated individual parts. Utilizing panels can significantly improve handling efficiency, eliminate the need for additional fixturing, and reduce overall production costs.

By adhering to these guidelines, you help us maintain the highest standards of quality and efficiency. Thank you for your cooperation and trust in PICA Manufacturing Solutions. Together, we can continue to achieve exceptional outcomes in every project.