PICA Manufacturing Solutions Defense & Security

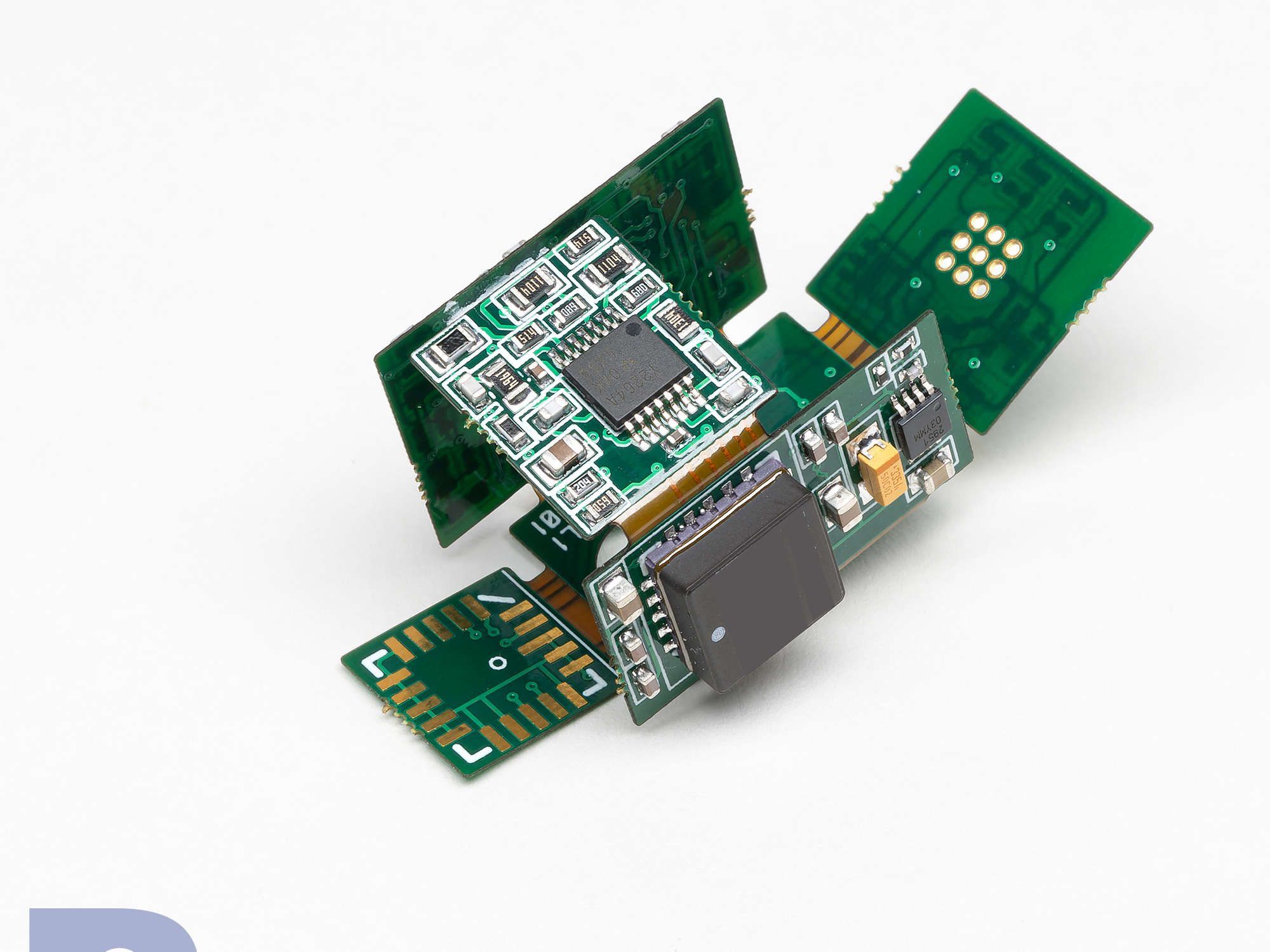

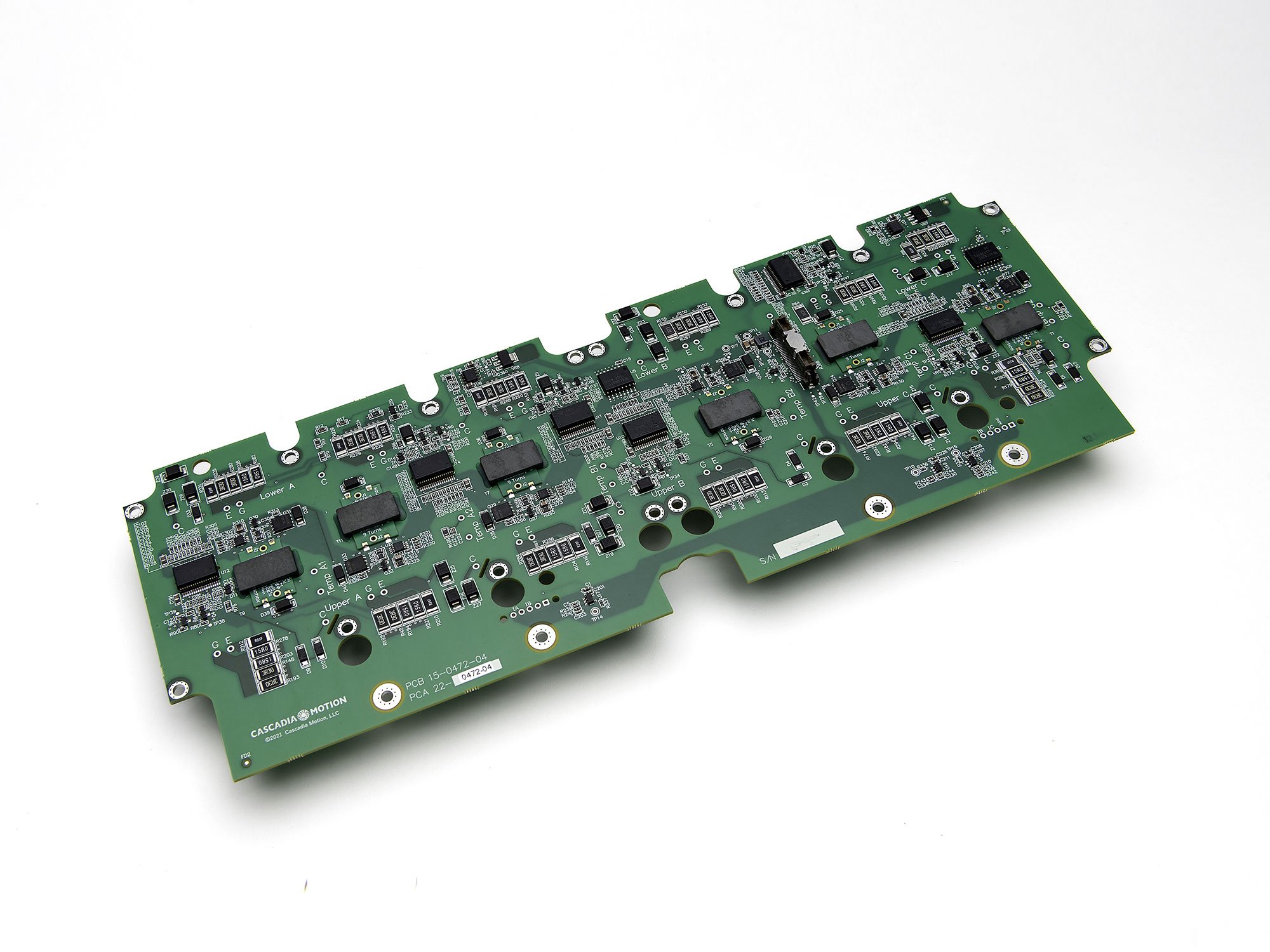

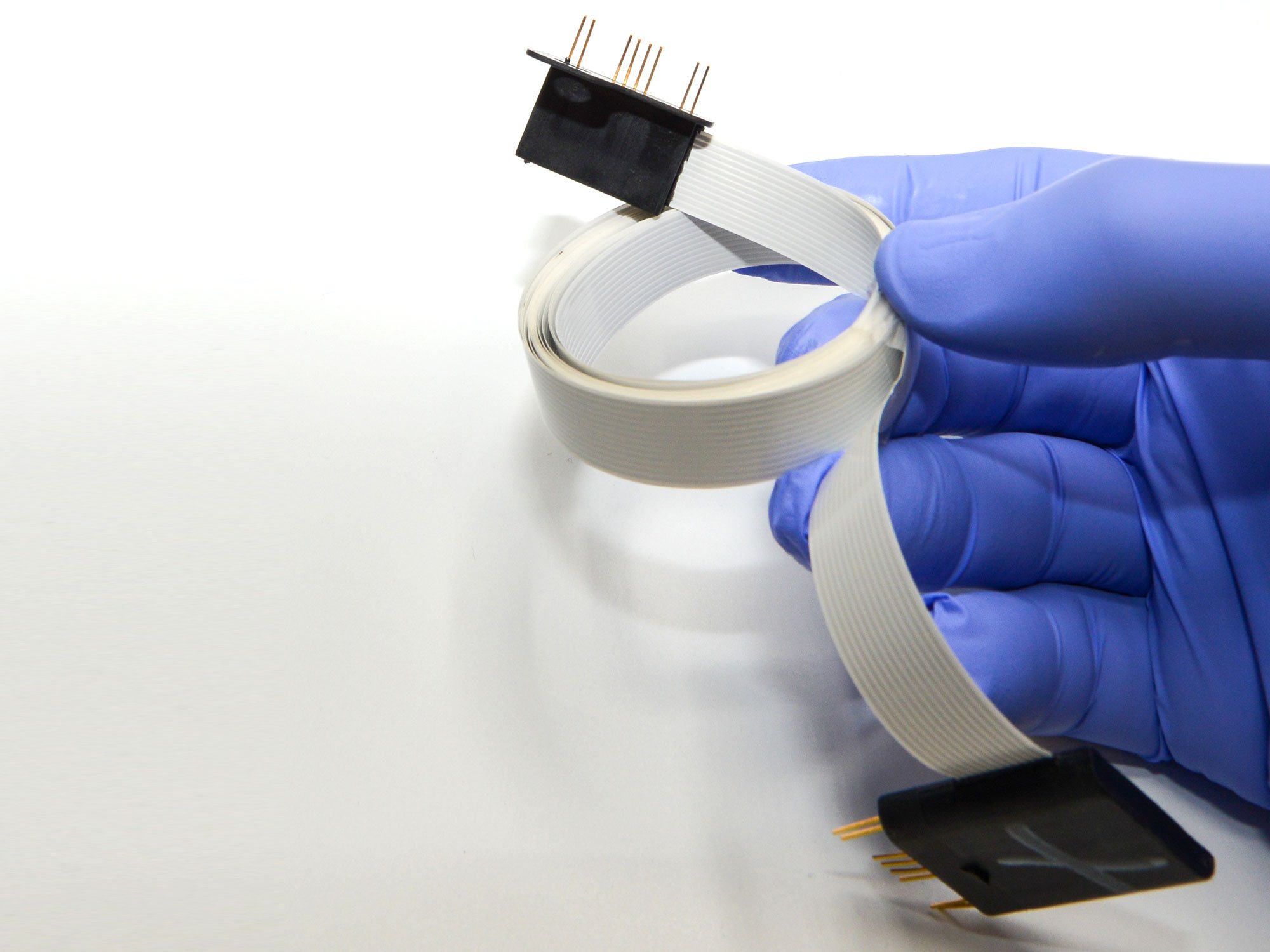

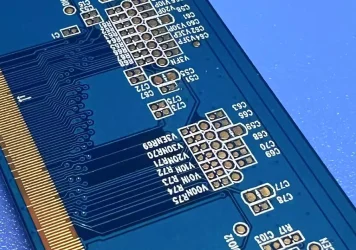

PICA Manufacturing Solutions delivers rugged, secure, and miniaturized flex and rigid PCB technology designed for mission-critical defense and security applications. Our designs meet stringent military and industry standards, providing the reliability, protection, and performance essential for operations where there is no room for failure.

We enable innovation across a broad spectrum of submarkets:

Military Application

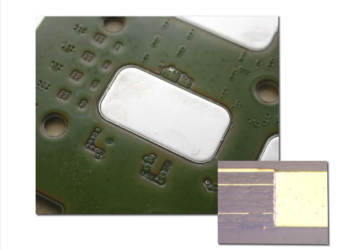

From soldier-worn electronics to battlefield communication systems, defense hardware demands high-reliability flex and rigid PCBs built to strict standards such as MIL-STD and IPC Class 3. PICA produces boards engineered for harsh conditions, extended life cycles, and absolute performance in the field.

Law Enforcement & Public Safety

Body cameras, vehicle-mounted systems, and secure communication devices require protection against tampering, reverse engineering, and counterfeit components. PICA’s designs integrate hardware-level safeguards while maintaining consistent performance in high-stakes environments.

PICA Manufacturing Solutions combines rugged construction, advanced security features, and compliance with military-grade standards to deliver flex and rigid PCB solutions that protect lives, information, and mission success.

Equip your mission with proven reliability. Fill out our form to see how PICA can deliver secure, high-performance PCBs for defense and security.

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing When it comes to PCB and flex circuit manufacturing,...

Guide to PCB & FPC Manufacturing Processes

This blog is an excerpt from the white paper Guide to PCB & FPC Manufacturing Processes: Subtractive, Semi-Additive & Additive...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...