Cryogenic Electronics Research

Introduction: Supporting Academia to Advance the Sciences

At PICA Manufacturing Solutions, we support advancements in quantum computing by partnering with researchers who are pushing the limits of electronics performance in extreme environments. PICA collaborates with academic institutions and research programs to help translate quantum computing concepts into manufacturable hardware suitable for cryogenic operation. Through engineering expertise, materials insight, and prototyping support, we enable researchers to evaluate new interconnect technologies critical to next-generation quantum systems.

This project reflects PICA’s commitment to advancing quantum computing research by bridging academic innovation with real-world electronics manufacturing.

Project Overview

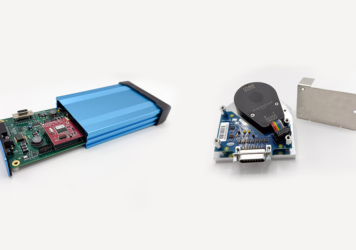

PICA supported a university-led research initiative focused on electronic interconnects operating at cryogenic temperatures below 4 Kelvin. These extreme conditions are common in quantum computing systems and advanced low-temperature physics research, where traditional wiring harnesses introduce thermal, mechanical, and scalability challenges.

The goal of the project was to evaluate the feasibility of fully adhesiveless flexible printed circuits as a replacement for conventional wiring in quantum computing cryostats, focusing on reduced thermal loading, improved mechanical stability during thermal cycling, and support for higher-density interconnects at cryogenic temperatures.

Application

This project focused on electronic interconnects for cryogenic systems operating below 4 Kelvin. These systems are relevant to quantum computing platforms, cryogenic instrumentation, and advanced low-temperature physics research, where minimizing thermal load and maintaining reliable electrical performance are critical.

Project Objectives

The objective was to replace traditional wiring harnesses with flexible circuits in order to reduce thermal load, improve mechanical stability, and enable higher-density interconnects suitable for cryogenic environments.

Technology Focus

The project emphasized the following technical elements:

- Fully adhesiveless polyimide-based flex PCB construction

- Elimination of adhesive layers to improve reliability at ultra-low temperatures

- Reduced copper mass to minimize heat transfer into the cryogenic environment

Electrical Requirements

The electrical design requirements included:

- Support for high-speed differential signaling

- Controlled impedance routing at 100 ohms differential in a flex format

PICA Engineering Scope

PICA provided engineering and manufacturing support across multiple phases of the project, including:

- Stackup concept development and material selection for cryogenic operation

- Manufacturability assessment for ultra-thin, adhesiveless flex constructions

- Prototype fabrication to validate feasibility and design assumptions

Results and Outcomes

The project achieved the following outcomes:

- Early-stage evaluations demonstrated the feasibility of adhesiveless flex circuits for operation in sub-4 Kelvin cryogenic environments, supporting their potential use in quantum computing applications.

- Cryogenic testing was scheduled following sample receipt, with evaluation planned under representative operating conditions relevant to quantum computing systems. Testing focus areas include mechanical robustness, stability during thermal contraction, and overall suitability for use inside quantum computing cryostats.

- If testing is successful, the research team has expressed interest in future iterations of the flex design, including more advanced versions aligned with evolving quantum computing research requirements.

Impact and Relevance

This project demonstrates the relevance of adhesiveless flex PCB technology for quantum computing platforms operating in cryogenic environments. Positive initial inspection results and forthcoming cryogenic validation position adhesiveless flex circuits as a promising interconnect solution for next-generation quantum computing research systems. The work further reinforces PICA’s capability to translate advanced academic research into manufacturable, extreme-environment hardware.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

CES 2026 Highlights: The Breakthrough Technologies Powered by Advanced Flex & PCB Design

Las Vegas, January 2026 — CES 2026 once again confirmed that the pace of innovation in consumer tech, mobility,...

What Is Box Build Assembly? Process, Benefits & How to Choose a Manufacturer

Box build assembly—sometimes called systems integration—involves assembling a complete electronic product by combining a finished PCBA with...

Designing PCBs for Medical Devices: Key Considerations & Compliance Tips

PCB design for medical electronics demands more than just electrical functionality. Devices must meet...

What to Look for in a Manufacturing Company in Malaysia

When evaluating a manufacturing company in Malaysia, most teams are focused on a few essentials: capability fit, reliable quality systems,...