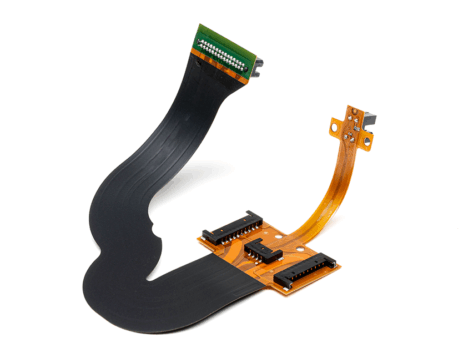

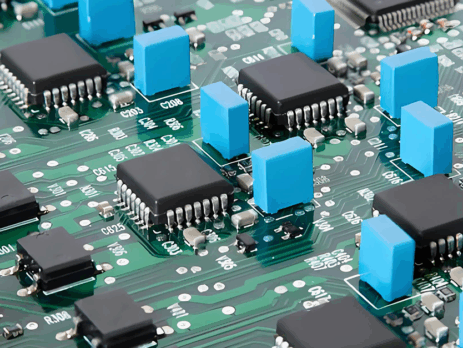

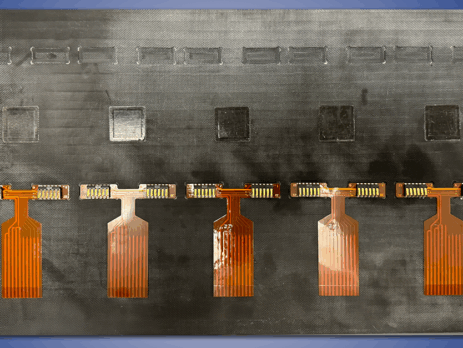

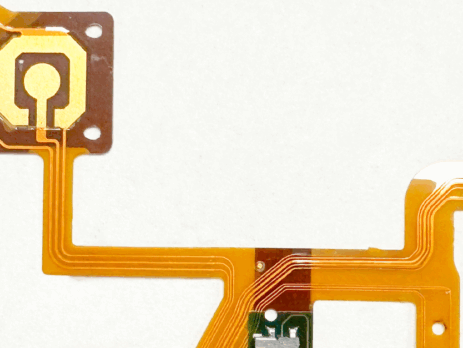

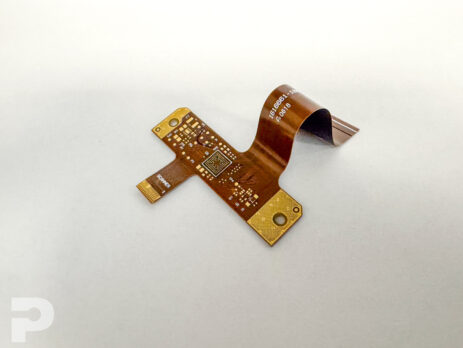

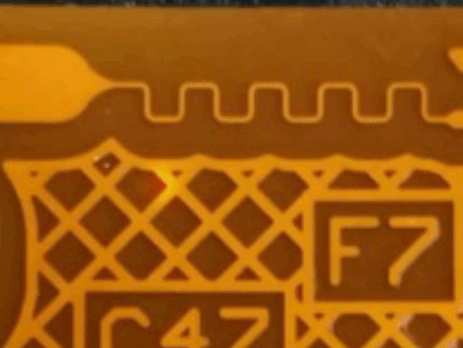

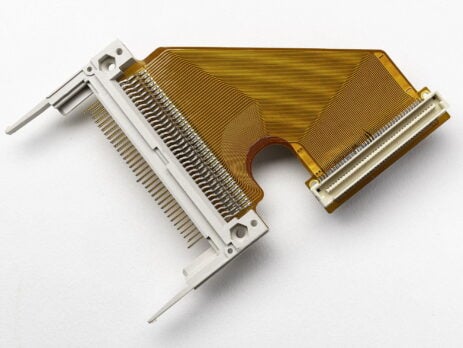

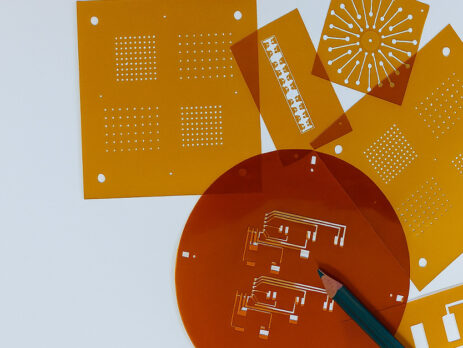

Biocompatible Substrates for Flex and Rigid PCBs

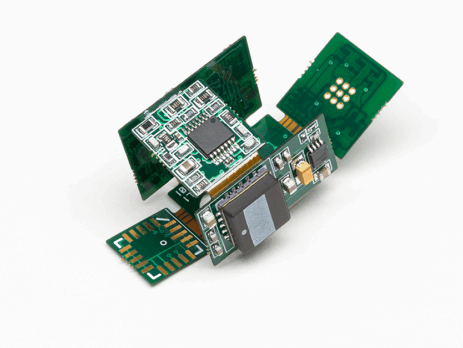

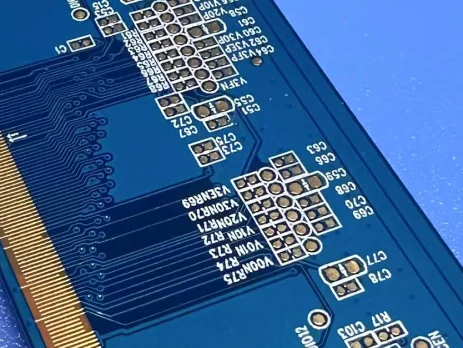

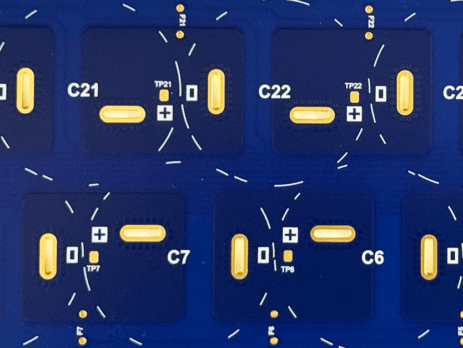

In the expanding world of medical devices, and wearables, the demand for biocompatible substrates in flex and rigid PCBs has never been greater. As electronic systems move closer to and even into the human body, designers and manufacturers must ensure that every...