PICA Manufacturing Solutions Wearables Market

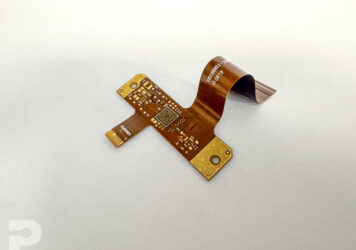

PICA Manufacturing Solutions designs and builds ultra-flexible, lightweight flex and rigid PCBs and assemblies engineered for comfort, safety, and performance in wearable technology. Whether for fitness tracking, tactical operations, or healthcare monitoring, our solutions combine durability, precision, and skin-contact safety to seamlessly integrate with the body—or what it’s wearing.

We enable innovation across a broad spectrum of submarkets:

Consumer Fitness Devices

From smartwatches to fitness bands and body sensors, consumer wearables demand compact, lightweight flex and rigid PCBs that fit into small, often non-rectangular enclosures. PICA’s designs ensure reliable performance without compromising comfort or style.

Military / Tactical Wearables

Soldier tracking and communication systems require rugged electronics with optimized routing and custom board shapes. PICA delivers mission-ready solutions that prioritize space efficiency and operational reliability in challenging conditions.

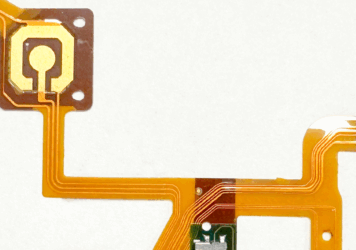

Textile-Integrated Electronics

Smart garments and uniforms with embedded flex circuits must endure bending, impacts, sweat, and humidity. PICA creates flexible, resilient flex and rigid PCBs that maintain performance even under repeated stress and environmental exposure.

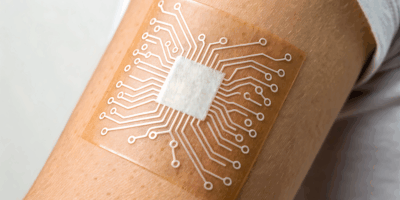

Healthcare Wearables

Clinical-grade trackers and posture monitors rely on small and sometimes flexible batteries, making power management and energy efficiency essential. PICA develops electronics that maximize battery life while meeting strict healthcare device standards.

Sports Tech

From biometric helmet sensors to smart pads like sweat sensors, sports tech wearables require EMI/EMC compliance and a comfortable fit. PICA produces precision flex and rigid PCBs that integrate seamlessly into gear without hindering performance or comfort.

PICA Manufacturing Solutions blends precision engineering with human-focused design to deliver wearable electronics that are lightweight, safe, and built to perform. Whether on the field, in the gym, or in critical care, our flex and rigid PCBs keep your technology close—literally.

Bring your wearable innovation to life. Fill out our form and let PICA create the flexible, durable PCBs your design needs.

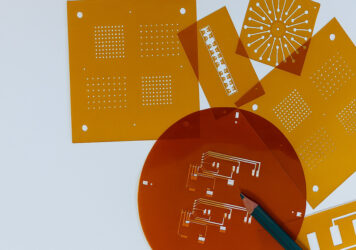

Biocompatible Substrates for Flex and Rigid PCBs

In the expanding world of medical devices, and wearables, the demand for biocompatible substrates...

Advanced Trace Routing Techniques for Flexible PCBs: Boost Reliability and Performance

Designing a flexible PCB is not just about taking the layout practices from

Mastering Thermal Management in PCB and Flex Circuit Design

As electronic devices become more compact and powerful, managing heat effectively is critical to ensuring performance, reliability, and long product...

Step-by-Step Guide to the Flex Printed Circuit Board Assembly (FPCBA) Process

IntroductionAs electronics evolve to become thinner, lighter, and more complex, Flex Printed Circuit Boards (FPCBs) have emerged...

Designing for Precision: Controlled Impedance in Flexible Circuits

As electronic devices shrink and signal speeds increase, one design requirement becomes mission-critical: controlled impedance. This is...

Bending Without Breaking: How Flexible Circuits Are Tested for Reliability

Flexible circuits are built to bend—but only when designed and tested to handle real-world mechanical demands. Whether...

Embedding Performance: How Passive Components Are Integrated into Flexible Circuits

As electronic devices evolve to become smaller, smarter, and more power-efficient, engineers are under increasing pressure to maximize performance within...

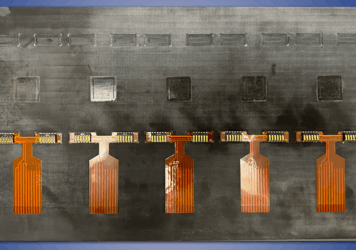

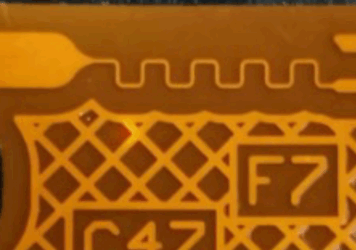

Kapton Etching in Flex Circuit Manufacturing: Processes, Materials, and Considerations

In the world of flexible electronics, polyimide films like Kapton® (a DuPont trademark) are a foundational material. Used in everything...