Note: with serious and intentional regard for our customer’s privacy, we do not mention the name of the customer in the case study.

The Customer:

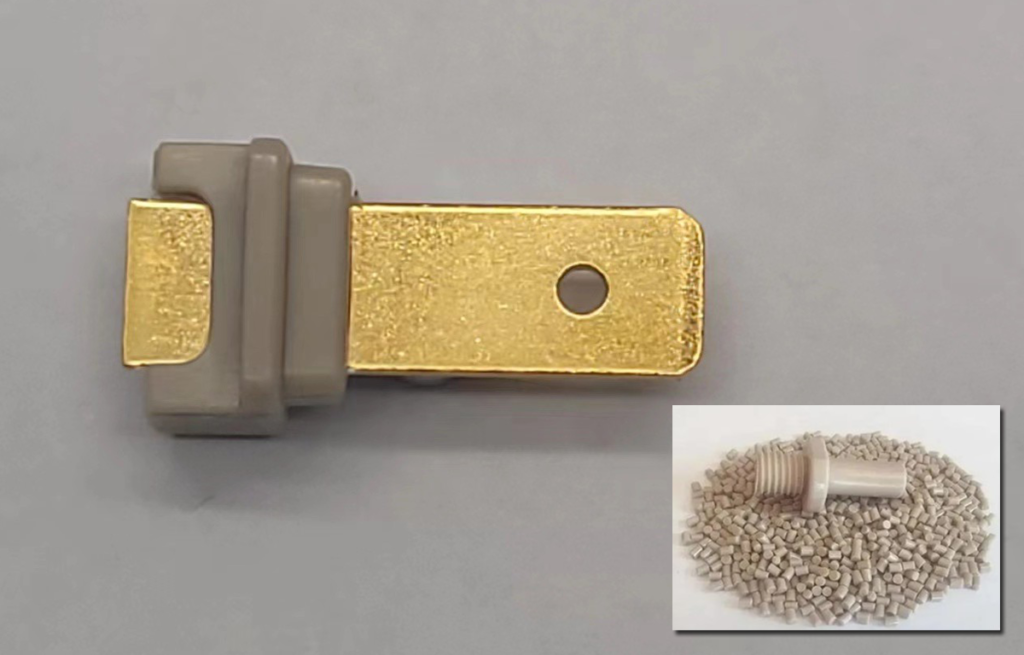

A leading company specializing in high-power semiconductor and fiber lasers for diverse applications, including industrial, microfabrication, aerospace, and defense sectors, required a material solution for their laser connector products that met stringent internal performance criteria. To meet these specialized needs, PICA recommended the use of PEEK (polyetheretherketone) material, known for its exceptional mechanical strength, high-temperature resistance, chemical resistance, wear resistance, and fatigue resistance. This material stands out for its superior properties compared to general engineering plastics, offering performance levels that approach those of metal materials.

The Challenge:

The challenge in using PEEK material stems from its processing difficulties, including high processing temperatures, high melt viscosity, poor fluidity, significant shrinkage, and high demands on mold wear and processing precision. These factors make the material complex to handle despite its superior performance, requiring sophisticated equipment and expertise for effective management during manufacturing.

The PICA Solution:

In response to these challenges, PICA adopted a comprehensive approach, selecting the appropriate processing equipment and continuously optimizing the injection molding process parameters. The company also chose suitable mold materials and designed molds rationally to navigate the demanding processing requirements of PEEK. These measures significantly improved the processing quality of the PEEK material. Moreover, PICA strengthened quality control throughout the processing phase to maintain the highest standards.

The Result:

The outcome of PICA’s approach was a 100% customer satisfaction rate, underscoring the effectiveness of their strategy in addressing the challenges of processing PEEK material. By surmounting the difficulties associated with PEEK, PICA successfully fulfilled the high-performance requirements for the laser connector products of a leading company in the semiconductor and fiber laser industry, demonstrating the exceptional potential of PEEK material when managed with expert knowledge and specialized equipment.