Note: with serious and intentional regard for our customer’s privacy, we do not mention the name of the customer in the case study.

The Customer:

A renowned multinational company, well known for its pioneering work in imaging and photography. They have developed a cutting-edge inkjet printing system that is highly regarded for its precision, reliability, and versatility in various applications including graphic arts, electronics, and material deposition.

The Challenge:

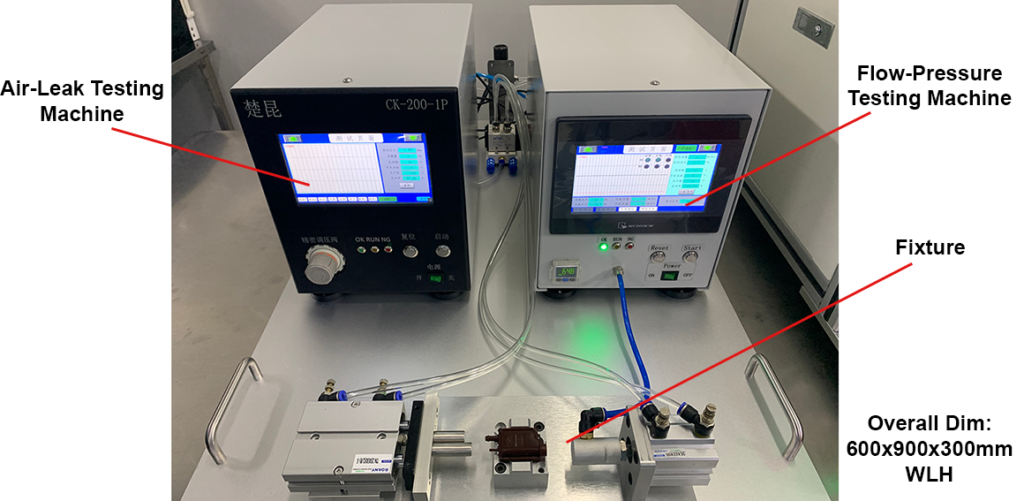

To address the need for stable internal performance in filter products, PICA developed a specialized detection instrument to match the unique requirements of customer products. This instrument is crucial for products needing consistent internal flow channel characteristics and overall sealing, such as various filters. It includes two functional parts: “Flow-Pressure” detection and an” Air-Leak” detection. The “Flow-Pressure” detection evaluates if the internal dimensions of the flow channel align with design specifications, while” Air-Leak” detection ensures the product’s overall sealing integrity.

The PICA Solution:

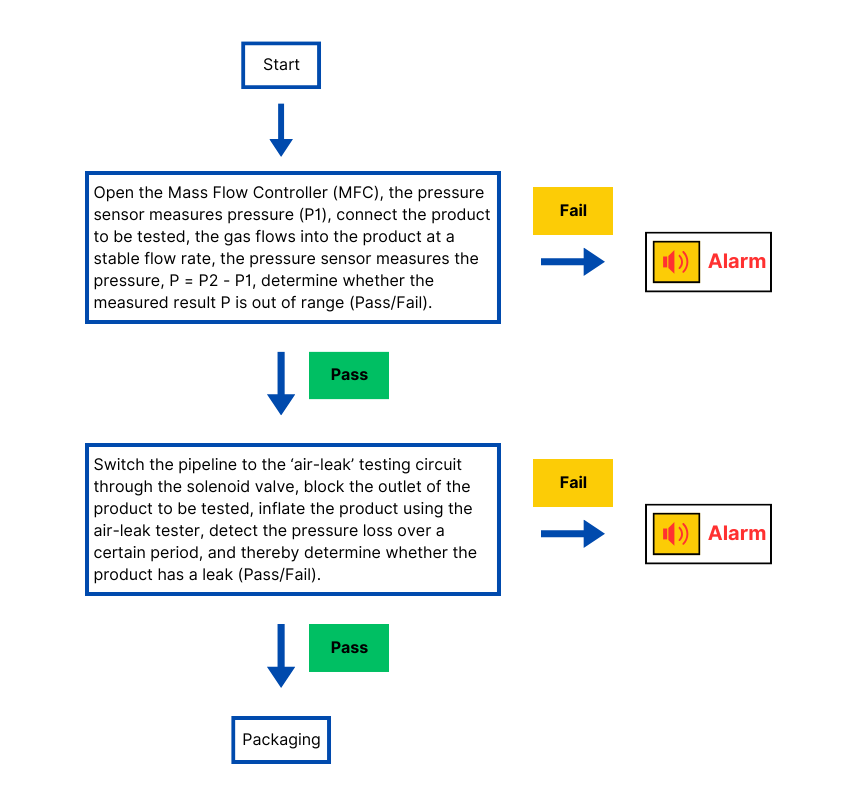

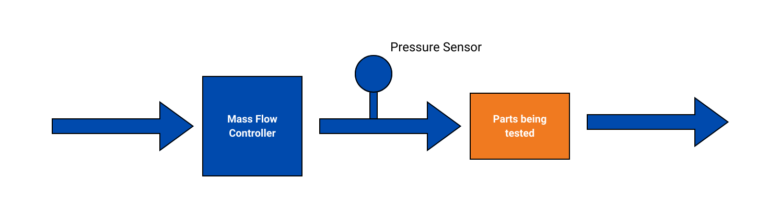

The “Flow-Pressure” test operates on the principle that obstructions in a gas flow channel cause pressure change. By measuring the gas pressure before and after connecting the product at a stable flow rate, the internal flow conditions are assessed. This is facilitated by the Mass Flow Controller (MFC), which maintains a consistent gas flow, and a pressure sensor to measure pressure variations (P1 before the product connection and P2 after). The result is expressed as P = P2 – P1. Following the “Flow-Pressure” test, the system automatically seals the product outlet and initiates the” Air-Leak” test. This phase involves inflating the product and measuring pressure changes over time to detect leaks. The integration of these two tests—enabled through signal communication between the testers—allows for comprehensive and automated control of the entire machine.

The following diagram illustrates the principles:

The Result:

The combined approach of “Flow-Pressure” and” Air-Leak” testing provides a robust solution for ensuring product quality. The ability to detect both flow channel conditions and sealing integrity in a single system streamlines the testing process. This innovative approach by PICA not only meets the stringent requirements for internal stability in filter products but also offers a versatile solution applicable to a range of products requiring precise internal flow and sealing characteristics. The outcome is a highly efficient and reliable testing mechanism, enhancing product quality and customer satisfaction.

The control logic of the entire machine is as follows: