Heavy Copper Printed Circuits

High Current, High-Reliability PCBs Built for Power & Performance

Heavy-copper PCBs use significantly thicker copper layers to handle high currents, improve thermal dissipation, reduce impedance, and deliver enhanced mechanical toughness in demanding environments. PICA’s heavy-copper capability supports power-electronics, automotive, industrial, and defense applications that demand more than a standard PCB.

Why Choose Heavy Copper Printed Circuits?

- Massive Current-Handling Capacity – Heavy copper layers allow high-current traces, bussing and plane structures far beyond standard boards.

- Enhanced Heat Management & Thermal Stability – Thicker copper and optimized via/plane structures pull heat from high-power components and reduce risk of thermal fatigue.

- Layer Count & Footprint Efficiency – With heavy copper, power and control circuitry can often be combined, reducing layer count and board size.

- Mechanical & Environmental Durability – Boards with heavy copper can survive thermal cycling, mechanical stress, and harsh conditions better than standard copper builds.

- Design Flexibility for Special Use Cases – Mixed copper weights on-board, heavy-copper pads and heat-sink interfacing, and strong capability for power/bus planes.

Heavy Copper Capabilities – Highlights

- Finished copper weights from 3 oz and above, with builds up to 10 oz+, 20 oz+ (depending on design).

- Heavy copper plating for via sidewalls and planes, enabling high-current through-holes and strong thermal pathways.

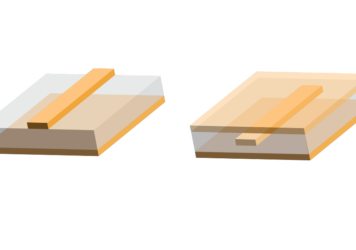

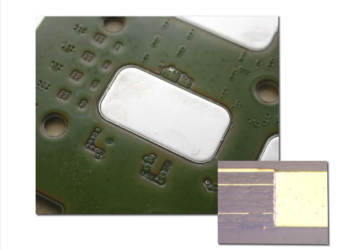

- Integrated heat-sink style copper elements or embedded buss plates within the PCB structure for thermal & power performance.

- Mixed copper weights on a single layer—power traces heavily plated, control signals standard copper—enabling layer-count optimization.

- Robust design workflows: early DFM for heavy copper routing, copper thickness analysis, thermal dissipation modelling and manufacturability feedback.

- Prototype to volume production scalability with heavy-copper build process controls and quality assurance.

For technical information on PICA’s Engineering expertise, click the button below.

Global Design & Manufacturing Support

PICA supports heavy-copper builds from concept to production across global engineering and manufacturing sites. Early collaboration ensures correct copper weight selection, trace/plane geometry, thermal path definition, and manufacturable board architecture that meets high current, thermal and reliability targets.

Benefits of Heavy Copper Printed Circuits

High-Power Ready

Heavy-copper PCBs handle large current densities and high power loads with fewer constraints than standard builds—enabling durable power distribution and bus architectures.

Superior Thermal & Electrical Performance

Thicker copper lowers board impedance, improves heat spread, reduces hot spots and supports stable performance under higher duty cycles.

Reduced Board Size & Complexity

Power and control circuits can often be consolidated, layer count reduced, and board footprint minimized by leveraging heavy copper along with standard copper in hybrid layouts.

Enhanced Reliability

Heavy-copper boards are better positioned to resist thermal cycling, mechanical stress, vibration, and environmental extremes—ideal for automotive, industrial, defense, and rugged applications.

Flexible Design for Specialized Needs

From heavy-current bussing to embedded copper heat plates to hybrid copper-weights, these PCBs offer tailored solutions for emerging power systems and high-density power electronics.

Markets We Serve with Heavy Copper PCBs

Industrial Equipment & Power Conversion

Motor drives, inverters, UPS systems, welding controllers and heavy machinery require PCBs that can carry high current and tolerate harsh thermal/mechanical conditions.

Automotive & Electrification Systems

EV charging infrastructure, power-train modules, battery management systems, and vehicle power electronics leverage heavy copper for high-reliability and high-current performance.

Defense & Aerospace Electronics

Radar systems, power distribution panels, shipboard electronics, and rugged mission-critical platforms demand boards built with heavy copper to meet longevity, performance and environmental standards.

Renewables & Grid Infrastructure

Solar inverters, battery storage systems, grid power converters and renewable asset controllers require high-current PCBs capable of efficient heat dissipation and long life.

Telecommunications & Data Centres

Power distribution modules, converters for 5G/6G infrastructure, data-centre power supplies benefit from low-impedance heavy-copper boards to handle demanding loads and continuous operation.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

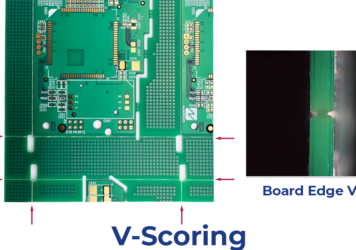

Choosing the Right PCB Separation Method: V-Scoring, Routing, and Die Cutting

Printed Circuit Board (PCB) manufacturing involves precise processes, not just in design and component assembly but also in how the...

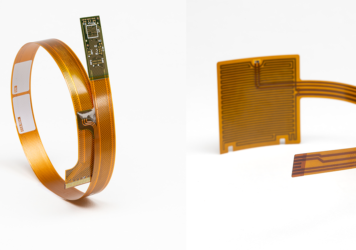

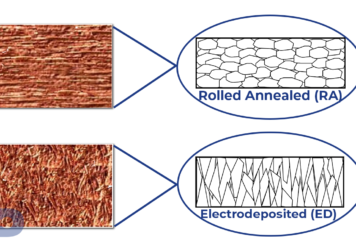

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

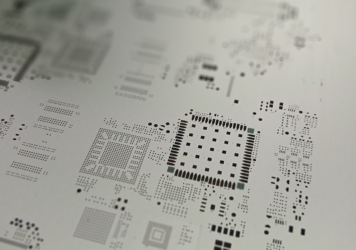

Printed Circuit Board (PCB) Stencil Design: Key Characteristics & Best Practices

Stencil design plays a critical role in ensuring the quality and reliability of printed circuit boards (PCBs). A well-designed stencil...

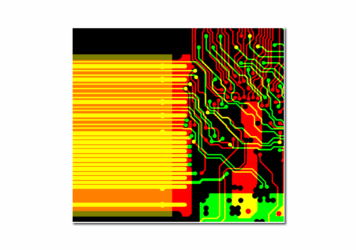

Controlled Impedance in Printed Circuit Board Design

In the design of printed circuit boards (PCBs), controlling impedance is a crucial factor for ensuring optimal signal integrity, especially...

The Best Copper Conductor for Flex-to-Install & Dynamic Applications

When it comes to choosing the right conductor material for flexible printed circuits (FPC), the primary consideration revolves around...

What is Differential Impedance?

In the fast-paced realm of the PCB (Printed Circuit Board) industry, achieving optimal signal integrity is crucial for the...

The Power of Embedded Passives

At PICA, we pride ourselves on being at the forefront of new technological advancements, including embedded passives. Through this blog...

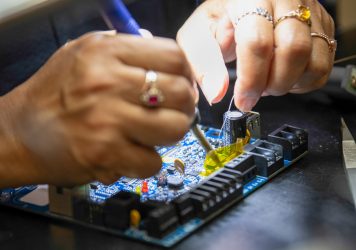

Large Thermal Mass Component Hand Soldering

While mass soldering processes dominate soldering applications, hand soldering remains critical in electronics manufacturing. Existing processes (e.g. convection oven reflow, vapor phase,...