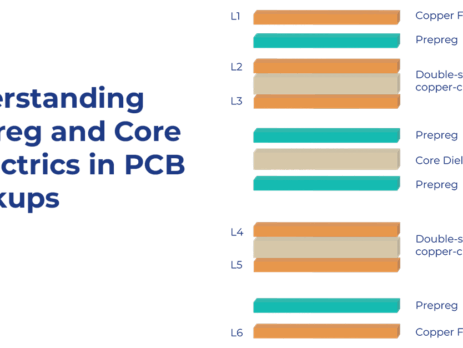

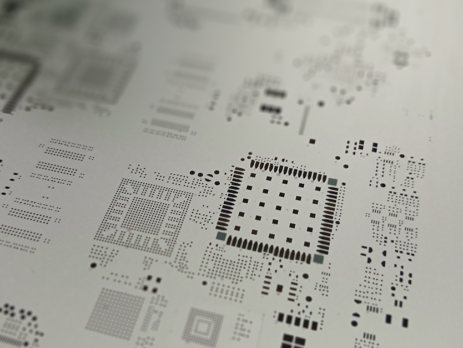

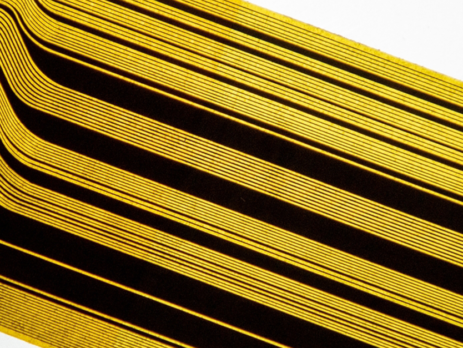

Understanding Prepreg and Core Dielectrics in PCB Stackups

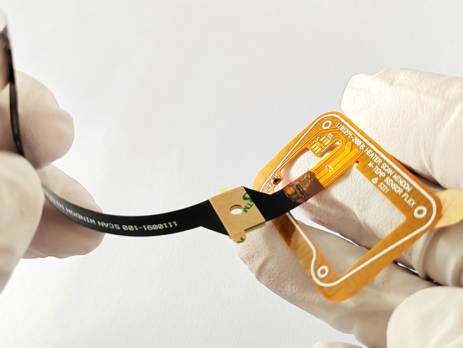

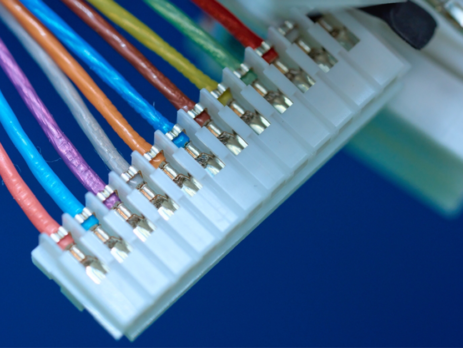

In multilayer PCB fabrication, what connects copper layers together isn’t just glue—it’s carefully engineered dielectric materials that control signal integrity, insulation, and mechanical performance. Among these, prepreg plays a critical role, serving as both an adhesive and an electrical insulator between copper layers. Whether you’re working on high-speed digital signals, RF layouts,...