Electrical Verification Protocols Part #2: Functional Testing of Complete Circuit Assemblies

Simon Lim2024-11-14T15:32:03+00:00Part #2: Functional Testing of Complete Circuit Assemblies

Introduction

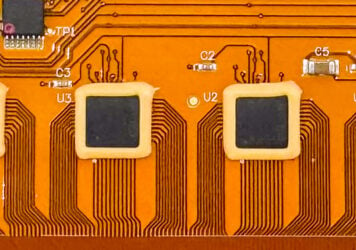

In the second part of our series, we delve into the verification processes for circuitry once components are mounted. This phase is crucial for assessing the functional integration and overall performance of our PCBs and FPCs. Through a series of targeted tests, we evaluate how individual components, and their interactions contribute to the circuit’s integrity, ensuring that each assembly meets our rigorous quality standards.

- Resistance, Capacitance, and Inductance Testing

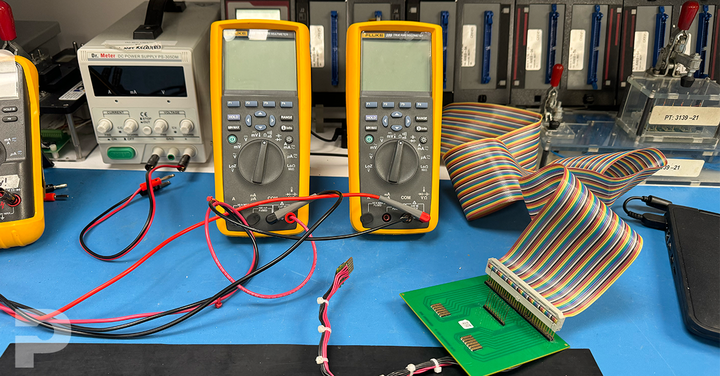

Testing the resistance, capacitance, and inductance is vital for verifying that components on PCBs adhere to their functional specifications. For these measurements, we employ LCR meters, which are versatile and precise instruments capable of assessing all three parameters.

Detailed Testing Methods

LCR Meter Testing: Our LCR meters are integral to our testing procedures. They provide accurate and comprehensive measurements of resistance, capacitance, and inductance. This multifunctional capability ensures that each component—whether a resistor, capacitor, or inductor—meets its specific requirements and performs reliably within the circuit. By confirming that these elements adhere to their design specifications, we enhance the overall functionality and reliability of our PCBs.

- In-Circuit Testing (ICT)

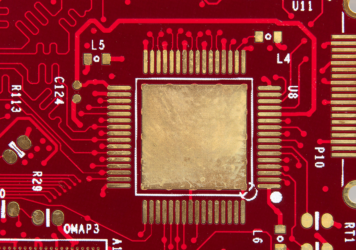

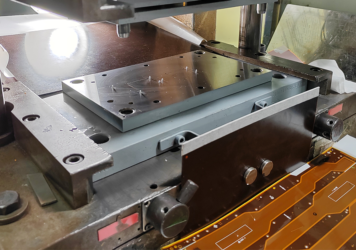

ICT is one of the most comprehensive methods used to check the assembly and functionality of components on a PCB. It’s particularly valuable for complex circuits with high component densities.

Methodology and Considerations

This test requires a specialized fixture that contacts test points on the PCB, allowing individual testing of each component for functionality and correct behavior. The test typically involves various voltages and currents, tailored to the specific components being tested. Although this method is more costly and time-consuming, its thoroughness makes it indispensable for ensuring that complex PCBs function correctly in their final applications.

Have you reviewed Part 1? Begin with the foundational insights on electrical verification in PCB manufacturing to fully benefit from Part 2. Click below to read part 1.

- Signal Integrity and Power Integrity Testing

We ensure that all signals and power distributions within the PCBs are optimal and meet operational standards.

Testing Protocols

Signal Integrity: Oscilloscopes analyze signal waveforms for any distortions or noise.

Power Integrity: Power analyzers measure voltage drops and current distribution to ensure stable power delivery to components.

- Cap Test: Specialized Capacitance Testing

The Cap Test is an essential procedure designed to verify the functionality and accuracy of capacitors within PCBs. It ensures that capacitors meet their specified values and perform reliably within their circuit applications.

Testing Process

Using targeted electrical signals, we measure each capacitor’s response to identify any performance discrepancies or deviations from expected values. This precise testing is crucial for applications where capacitor reliability is critical, such as in power supply circuits and signal filtering systems.

Conclusion

This discussion of our verification methods for assembled circuitry concludes our two-part series on electrical verification protocols. By rigorously testing circuitry with mounted components, we ensure that our products not only function according to technical specifications but also uphold the reliability and excellence expected by our customers. PICA Manufacturing Solutions remains dedicated to delivering top-tier PCBs and FPCs, reinforcing our commitment to quality and customer satisfaction in every piece we produce.